Tobacco seedling sowing method and equipment

A technology of tobacco seedlings and tobacco, which is applied in the field of tobacco seedling cultivation and sowing, and can solve problems such as low efficiency, inability to meet the large-scale cultivation of tobacco leaves, and high labor intensity of tobacco farmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

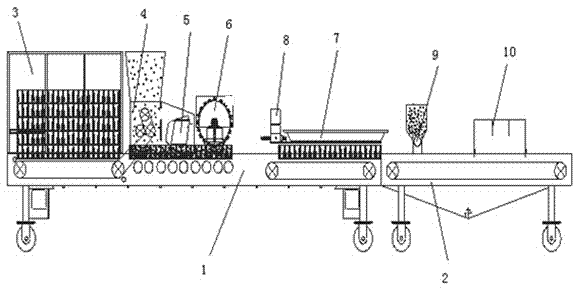

[0037] Such as figure 1 As shown, a tobacco seedling raising and sowing equipment is mainly composed of a frame I1 and a frame II2. Above the frame I1, a tray feeding device 3, a base loading device 4, and a flat tray are installed in a straight line. Disc device 5, pressure hole device 6, seeding device 7, electric control system 8, described electric control system 8 is installed on one end of seeding device 7; Above described frame II2 is installed in a straight line and sequentially arrange base-covering device 9 and cracking Device 10; said frame I1 and frame II2 are movable, and two universal wheels and two directional wheels are respectively installed on them.

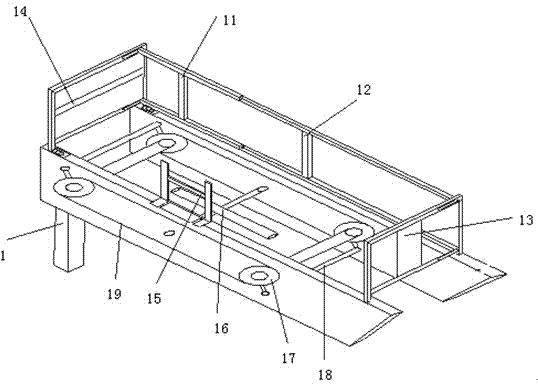

[0038] Such as figure 2 Shown, described disk advance device 3 comprises: put dish frame, power transmission mechanism 17, seedling dish slideway 16, and described dish frame is detachable structure by left block frame, front block frame 13, rear block frame 14, right block frame. Block frame 15 is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com