Rice straw returning seeding machine and rice straw returning sowing method

A rice straw and seeder technology, which is applied to harvesters, crop processors, agricultural machinery and implements, etc., can solve the problems of dead seedlings, increased harvest losses, and decreased farming quality, so as to improve threshing and separation capabilities, and reduce straws. Feed quantity, avoid the effect of uneven distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The steps of the method for sowing rice stalks in the present embodiment: one is to cut the stalk stubble in the paddy field with a length of 60 to 80 cm after harvesting, and collect the threshing effluent left on the field surface when the rice is harvested. Cut long stalks into crushed stalks no longer than 8cm in length; 2. Rotate the land and open ditches; The crushed straw is evenly covered on the field surface.

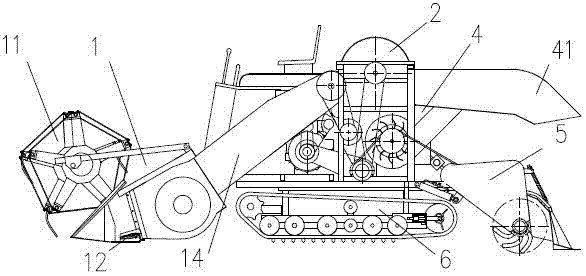

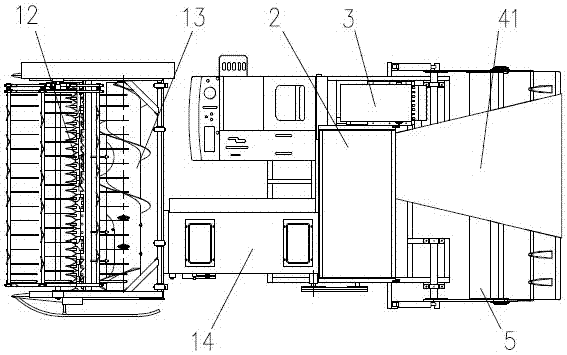

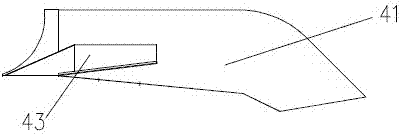

[0038] Such as Figure 1 to Figure 8 As shown, the rice straw returning planter in this embodiment is mainly composed of a crawler-type walking chassis 6, a straw cutting and conveying device 1 installed thereon, a straw chopping device 2, a seeding device 3, a broken straw spraying device 4 and Rotary tillage parts 5 are formed.

[0039] The straw cutting and conveying device 1 is composed of a straw picking wheel 11, a cutter 12, a transverse conveying mechanism 13 and a longitudinal conveying mechanism 14, and completes the picking, cutting and conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com