Grain discharging mechanism of harvester

A technology for harvesters and grains, which is applied to harvesters, agricultural machinery and implements, and applications. It can solve the problems of complex use, blockage of horizontal twisted cages, and poor grain flow, so as to achieve high discharge efficiency and avoid blockage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

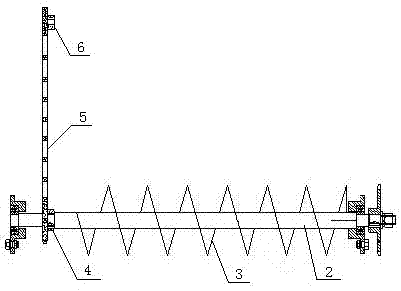

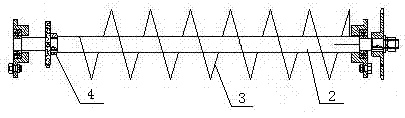

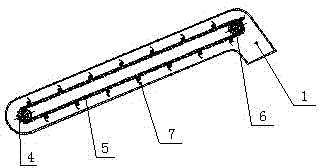

[0012] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] see figure 1 , figure 2 with image 3 As shown, the grain discharge mechanism includes a horizontal twist cage located in the threshing bin, a grain unloading cylinder 1 and a grain lifting mechanism located in the grain unloading cylinder 1 . Described horizontal strand cage comprises transmission shaft 2 and the blade 3 that is connected on transmission shaft 2, and described transmission shaft 2 is provided with the first sprocket 4 near one end of grain lifting mechanism; Described grain lifting mechanism comprises scraping grain chain plate 5 And the second sprocket 6, the outlet end of the second sprocket 6 installation unloading cylinder 1. The valley scraping chain plate 5 meshes with the first sprocket 4 and the second sprocket 6 respectively. A plurality of valley scrap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com