Preservative and film coating process for cooked salted duck eggs

A technology of coating preservatives and salted eggs, which is applied in the direction of coating protective layers to preserve eggs, etc., can solve the problems of plastic composite cooking bags that are not easy to degrade, salted duck egg shells are easily damaged, and product loss, etc., to reduce losses and reduce Production cost and usage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] First weigh 5 grams of film-forming agent, 10 grams of hydrophobic agent, 5 grams of disinfectant, and 1 gram of surfactant and mix thoroughly, then add 250 ml of acetic acid and water mixed solution with a volume ratio of 1:1, heat at 80 ° C, stir , 2 hours, until completely dissolved, and then diluted to 1000ml with a mixed solution of acetic acid and water with a volume ratio of 1:1.

[0016] The film-forming agent is one or two of polyvinyl alcohol (PVA) and chitosan (Chitosan).

[0017] The hydrophobic agent is one or more of food-grade stearic acid, glutaraldehyde, and whey protein concentrate.

[0018] The surfactant is one or two of nano-TiO2 and nano-SiO2.

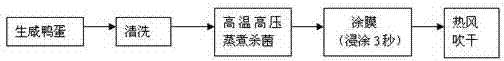

[0019] The present invention is applied to the fresh-keeping treatment of boiled salted duck eggs, and the technological process is:

[0020]

Embodiment 2

[0022] First weigh 10 grams of film-forming agent, 10 grams of hydrophobic agent, 5 grams of disinfectant, and 2 grams of surfactant and mix thoroughly, then add 250 ml of acetic acid and water mixed solution with a volume ratio of 1:1, heat at 80 ° C, stir , 2 hours, until completely dissolved, and then diluted to 1000ml with a mixed solution of acetic acid and water with a volume ratio of 1:1.

[0023] The film-forming agent is one or two of polyvinyl alcohol (PVA) and chitosan (Chitosan).

[0024] The hydrophobic agent is one or more of food-grade stearic acid, glutaraldehyde, and whey protein concentrate.

[0025] The surfactant is one or two of nano-TiO2 and nano-SiO2.

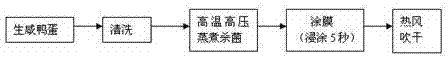

[0026] The present invention is applied to the fresh-keeping treatment of boiled salted duck eggs, and the technological process is:

[0027]

Embodiment 3

[0029] First weigh 10 grams of film-forming agent, 15 grams of hydrophobic agent, 5 grams of disinfectant, and 3 grams of surfactant and mix thoroughly, then add 250 ml of acetic acid and water mixed solution with a volume ratio of 1:2, heat at 80 ° C, stir , 2 hours, until completely dissolved, and then diluted to 1000ml with a mixed solution of acetic acid and water with a volume ratio of 1:2.

[0030] The film-forming agent is one or two of polyvinyl alcohol (PVA) and chitosan (Chitosan).

[0031] The hydrophobic agent is one or more of food-grade stearic acid, glutaraldehyde, and whey protein concentrate.

[0032] The surfactant is one or two of nano-TiO2 and nano-SiO2.

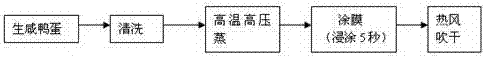

[0033] The present invention is applied to the fresh-keeping treatment of boiled salted duck eggs, and the technological process is:

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com