Handpiece capable of automatically locking by pressing central spindle and central spindle for handpiece

An automatic locking and pressing shaft core technology, which is applied in medical science, dentistry, dental drilling, etc., can solve the problems of pressing shaft core failure, burs flying out, and burs that cannot be clamped, so as to improve the clamping torque, The effect of prolonging the service life and improving the clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

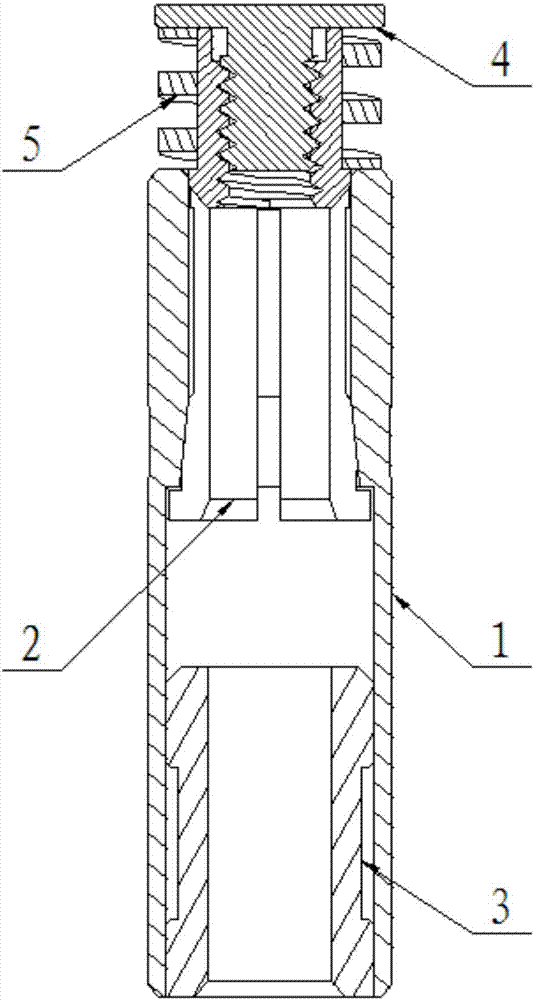

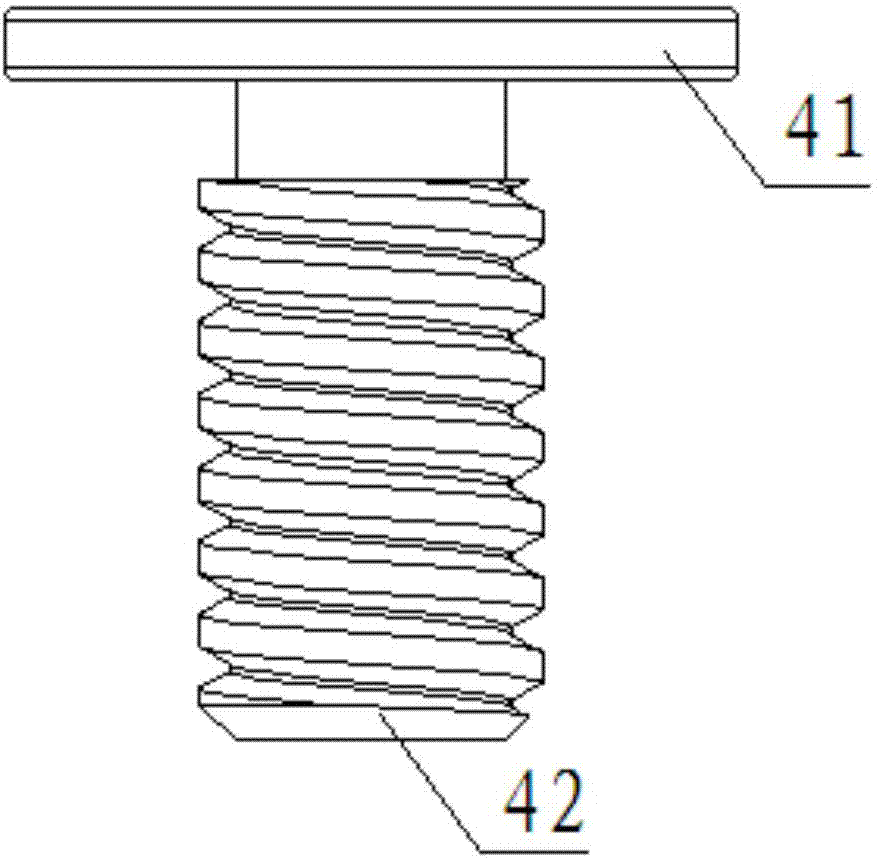

[0016] Such as figure 1 , figure 2 As shown, a shaft core for automatically locking a mobile phone by pressing the shaft core includes a bearing column 1 and a needle holder 2; the bearing column 1 is a cylindrical bushing with both ends open and hollow; A cylindrical meson 3 with an open end and a hollow; the clamping part 2 is nested in the upper end of the bearing column 1; the clamping part 2 is connected with a rebound device that controls its up and down movement so as to realize the disassembly and assembly of the bur; the rebound The device includes a spring 5 and a pressing piece 4, preferably: the pressing piece 4 is set in a T-shape; preferably: the spring 5 is made of a wire with a rectangular cross se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com