Filter assembly

A filter assembly and filter technology, which is applied in the direction of fixed filter elements, filter separation, chemical instruments and methods, etc., can solve the problems of increasing costs and achieve the effect of strong expansion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

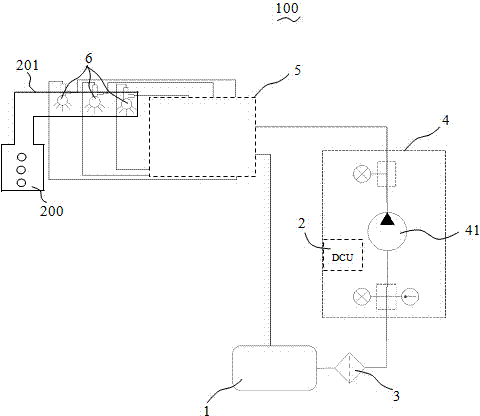

[0032] Please refer to figure 1 As shown, the present invention discloses an exhaust aftertreatment system 100 applicable to large engines, which includes a urea tank 1, a filter assembly 3 connected to the urea tank 1, and a fluid delivery system for delivering the urea solution device 4 , a common rail 5 connected to the fluid delivery device 4 , several nozzles 6 connected to the common rail 5 and a controller 2 for controlling the exhaust gas post-treatment system 100 .

[0033] In the illustrated embodiment of the present invention, the engine 200 is a high-power engine whose power generally exceeds 500 kilowatts. The fluid delivery device 4 is provided with a pump 41 (such as a gear pump, etc.) for pumping the urea solution. In the illustrated embodiment of the present invention, the controller 2 is installed on the fluid delivery device 4 to realize integration. The nozzle 6 is used to spray atomized urea solution into the engine exhaust pipe 201 . The atomized urea ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com