Method for automatically unloading drill bit

An automatic unloading and drilling technology, which is applied to drilling/drilling equipment, components of boring machines/drilling machines, metal processing equipment, etc., can solve the problems of complex disassembly methods, complicated operations, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

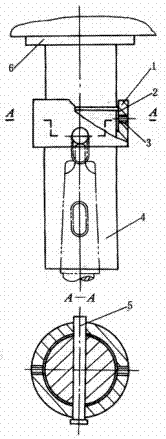

[0006] like figure 1 As shown, the operation steps of the present invention include: putting the ferrule 1 on the spindle 4 of the drilling machine, pushing it to the waist-shaped hole, inserting the cross pin 5 into the waist-shaped hole through the side hole of the ferrule, and the cross pin can be inserted into the waist-shaped hole. Slide up and down inside, the ferrule can slide on the drill spindle. In order to prevent the ferrule from falling off freely, a spring leaf 2 is clamped between the ferrule and the main shaft. When the main shaft is retracted upwards to a certain position after work, the ferrule collides with the fixed part 6 above, and the ferrule drives the cross pin to hit the tail end of the drill bit, and the drill bit is washed off from the taper hole of the main shaft.

[0007] By adopting the above steps, the disassembly process is simple and convenient, and the working hours are shortened.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com