Oval tube alignment method and laser cutting device

A technology of laser cutting and elliptical tubes, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of increasing production costs, increasing the labor load of production personnel, and unfavorable large-scale processing and production, and achieves strong versatility, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

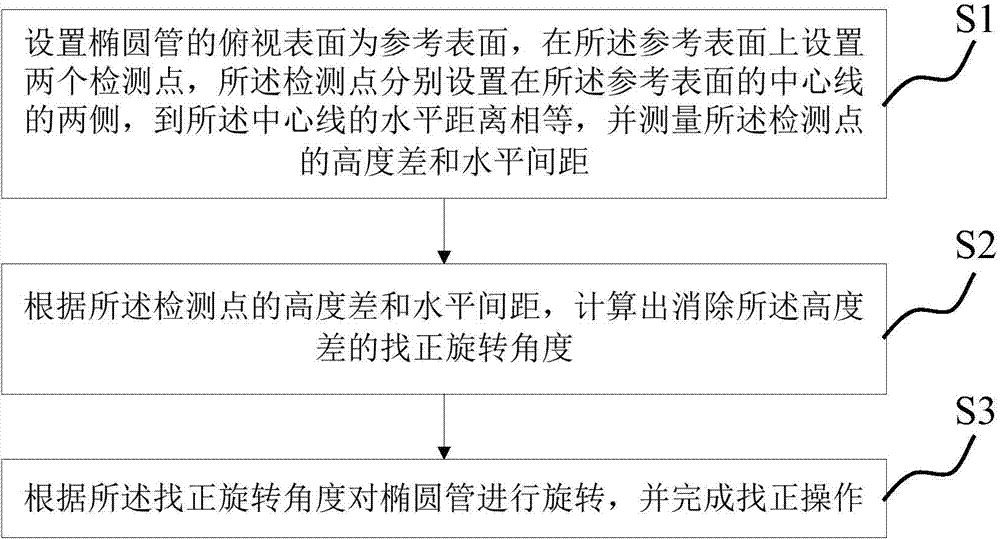

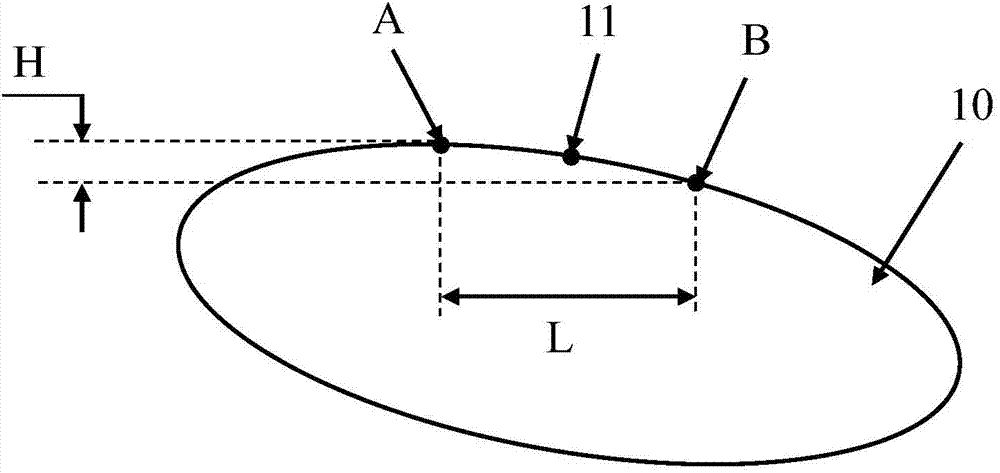

[0031] Such as Figure 2~4 As shown, the present invention provides a preferred embodiment of a method for aligning an elliptical pipe, wherein figure 2 is the principle block diagram of the alignment method, image 3 It is the detection indication of the correct method Figure 1 , Figure 4 It is the detection indication of the correct method Figure II .

[0032] A method for aligning an elliptical tube. The elliptical tube is clamped horizontally before the aligning operation. The steps include:

[0033] S1. Set the top view surface of the elliptical tube as the reference surface, set two detection points on the reference surface, the detection points are respectively arranged on both sides of the center line of the reference surface, and the horizontal distance to the center line are equal, and measure the height difference and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com