Apparatus and method for processing a torque request for an engine and to reduce driveline shocks

A technology for driving machinery and transmission lines, applied to control devices, transportation and packaging, and driver input parameters, etc., can solve problems such as incompatibility, undesirability, and great complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

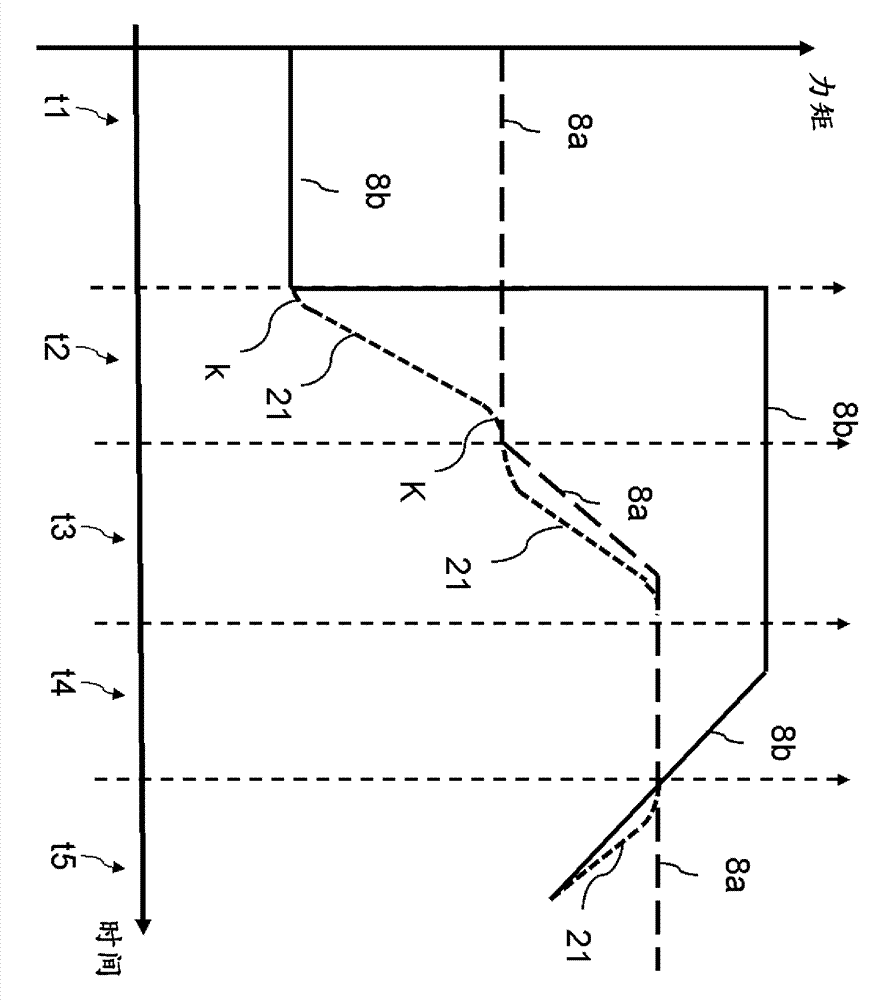

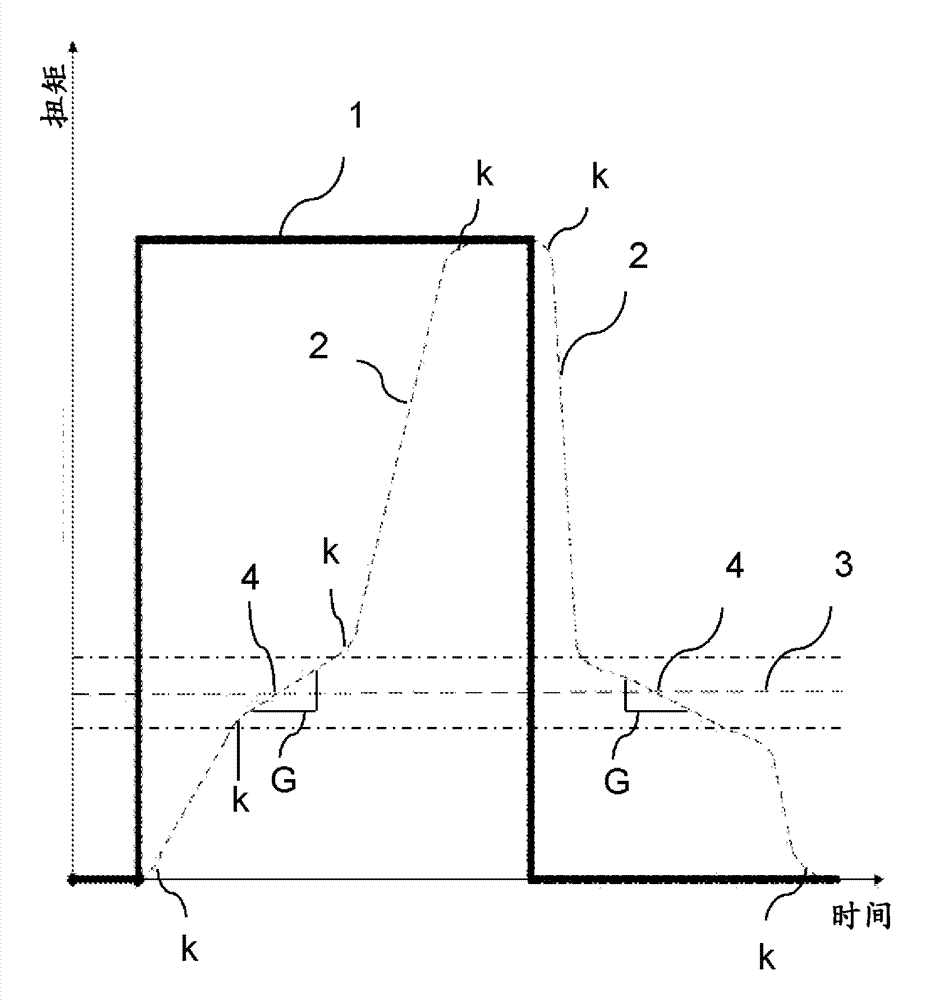

[0059] figure 1 As an example, an unfiltered torque preset 1 and a filtered torque request 2 are shown. Torque request 1 generated in the form of a rectangular function is passively filtered by a setpoint value converter (not shown) and output as filtered torque request 2 (dotted curve).

[0060] Torque request 1 can be generated, for example, by an accelerator pedal, a transmission clutch, a road speed regulator, a sound management system or other sources of torque requests. Torque request 1 can be generated as a torque preset or as a torque limit. A torque preset is understood to mean a setpoint value for the motor torque to be actuated, for which the injection quantity is to be set. Torque limitation is to be understood as a limit value over which the motor torque to be set should not be exceeded.

[0061] In accordance with the prior art, the edges of the rectangular function 1 are rounded by the theoretical value transformation device, which is achieved by figure 1 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com