A Simple Lock Body Mechanism

A lock body mechanism and simple technology, applied in the direction of building locks, building structure, construction, etc., can solve the problems of complex process, many accessories, and high cost, and achieve the effect of reducing the process, reducing the cost of raw materials, and reducing the opening process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

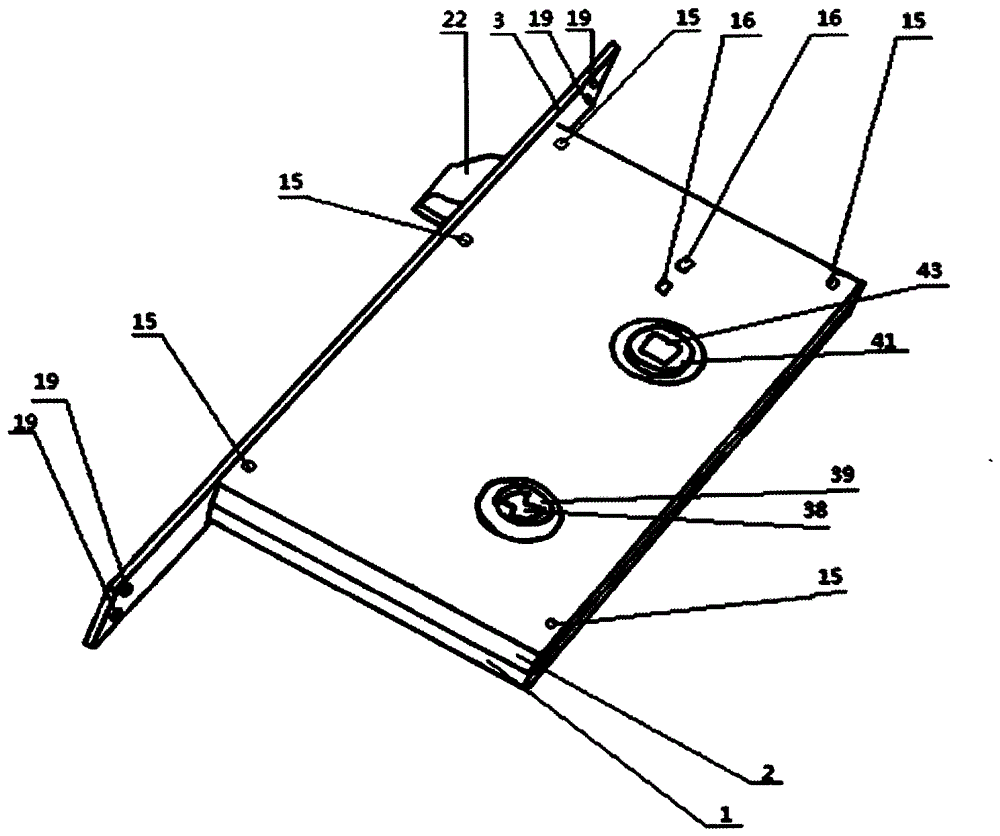

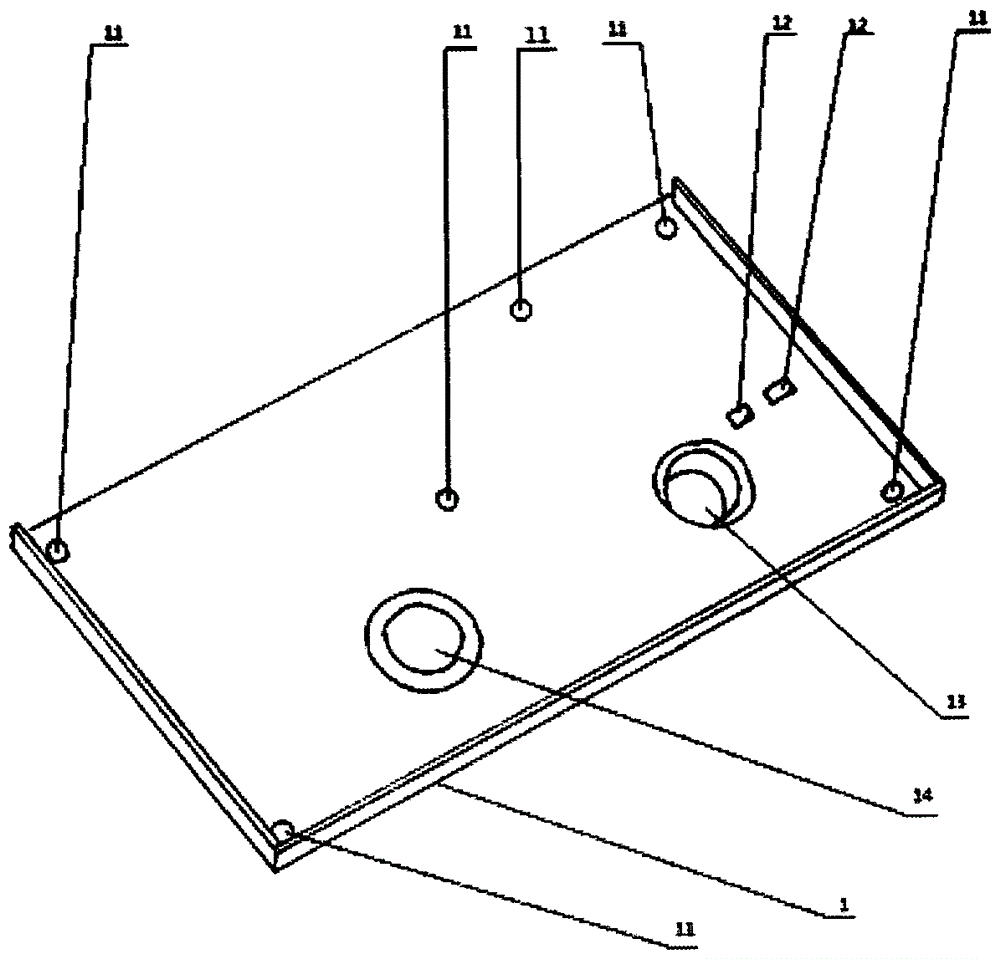

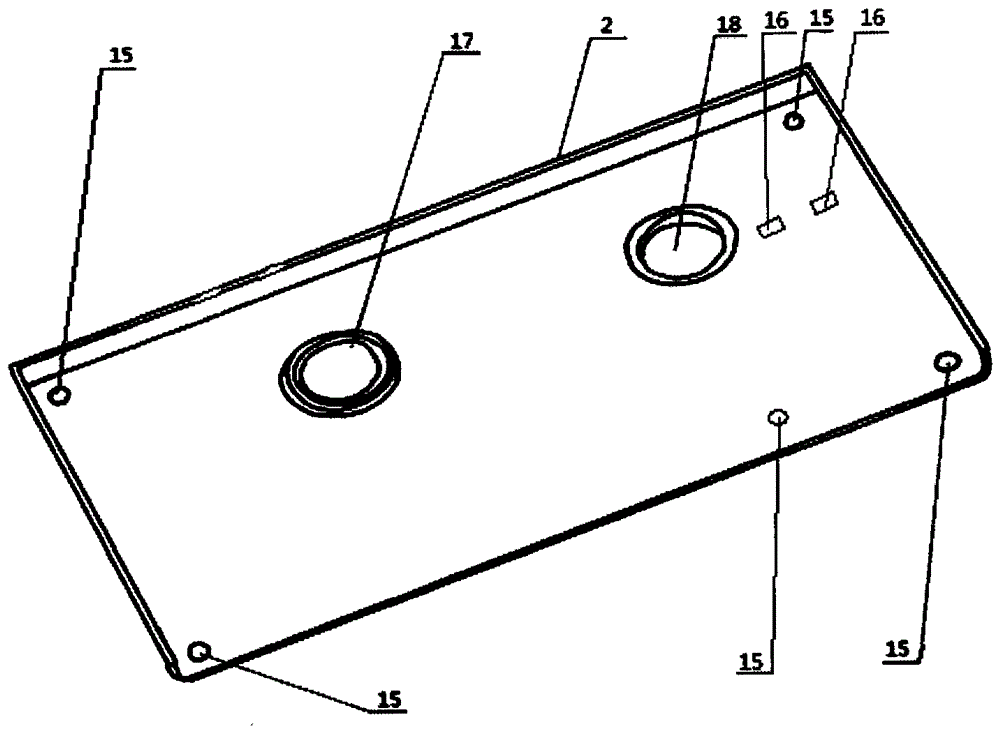

[0049] Now in conjunction with accompanying drawing, the present invention is described in detail:

[0050] The present invention is composed of base (1), loam cake (2), lock body panel (3), oblique lock piece (4), reverse bolt (5), powder-ink metallurgy (6), square hole shift fork (7), U-shaped seat (8), square hole shift fork control frame (9), connecting rod fixed seat frame (10) is formed.

[0051] figure 1 Shown is the structural representation of the present invention. Wherein, 1 is the base (1), 2 is the loam cake (2), 3 is the lock body panel (3), 15 is the screw hole two (15) that is provided with on the loam cake top plate, and 16 is on the loam cake top plate The fixed seat hole two (16) that is provided with on the top, 19 is the screw hole three (19) that is provided with on the lock body panel, and 22 is oblique deadbolt (22), and 38 is that set in the middle of guide post one. The square bar jack (38) that has, 39 is movable post one (39), and 41 is guide pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com