Underground net pipeline test method based on big dipper positioning

A Beidou positioning and testing method technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of inconvenient maintenance by managers, reduced sensing speed and sensing effect, and danger, and reduce pipeline maintenance costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

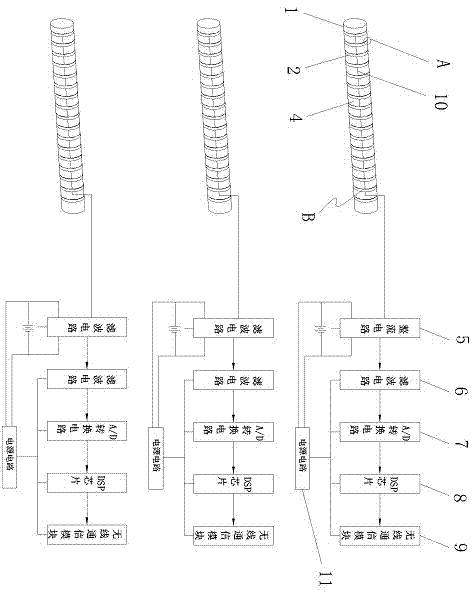

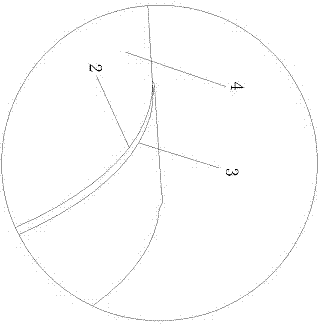

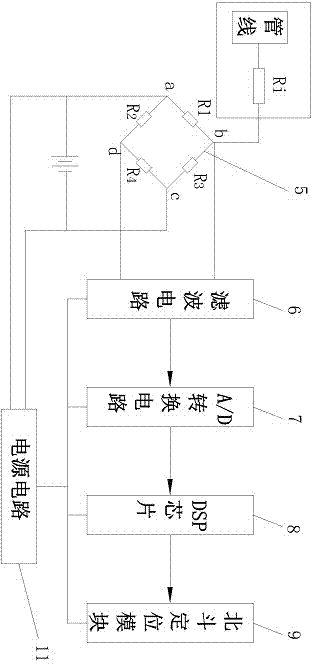

[0056] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 1, except that every n ring-shaped strained thin films 2 are connected in parallel through wires 10 to form a strained thin film group B. The equivalent circuit is also the same as that of the first embodiment. The equivalent resistance of the strained film group B is Ri, and this equivalent circuit is connected to the b terminal of the rectifier circuit 5. When the pipeline 1 is broken or slightly deformed, the corresponding annular strained film 2 is slightly deformed or broken, so that the strain The equivalent resistance Ri of film group B changes. At this time, the resistance value is sent to the main control circuit 8 after being passed through the rectification circuit 5, the filter circuit 6, and the A / D conversion circuit 7. After monitoring the corresponding resistance value, it can be obtained The equivalent resistance value of which strained film group B has changed, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com