Underground net pipeline test system based on big dipper positioning

A Beidou positioning and testing system technology, used in radio wave measurement systems, satellite radio beacon positioning systems, pipeline systems, etc., can solve the problems of inconvenient maintenance by managers, reduced sensing speed and sensing effect, casualties, etc. The effect of pipeline maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

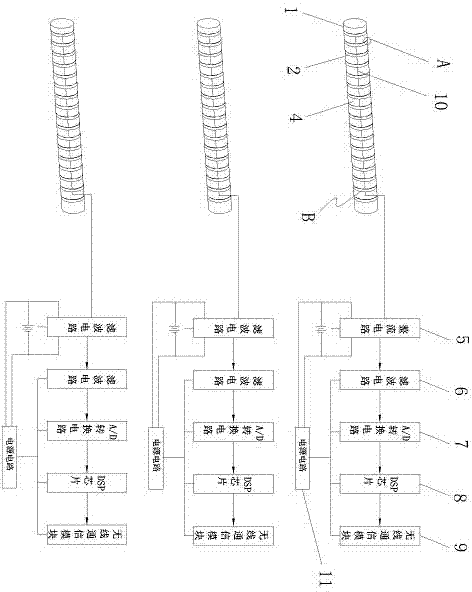

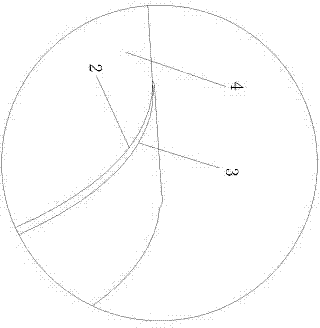

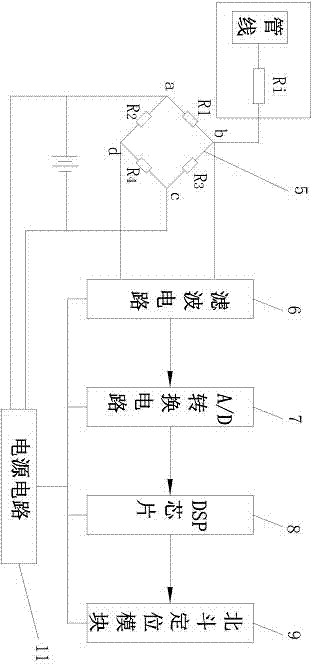

[0056] refer to Figure 4 As shown, this embodiment is basically the same as Embodiment 1, except that every n annular strained films 2 are connected in parallel through wires 10 to form a strained film group B. The equivalent circuit thereof is also the same as that of the first embodiment. The equivalent resistance of the strained film group B is Ri, and the equivalent circuit is connected to the b end of the rectifier circuit 5. When the pipeline 1 is broken or slightly deformed, the corresponding annular strained film 2 is slightly deformed or broken, which makes the strain The equivalent resistance Ri of the film group B changes. At this time, the resistance value is sent to the main control circuit 8 after the rectifier circuit 5, the filter circuit 6, and the A / D conversion circuit 7. Through the corresponding resistance value monitoring, it can be obtained The equivalent resistance value of which strained membrane group B has changed, and the calculation result is sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com