Device for measuring volume of warhead

A warhead and volume technology, applied in the field of devices for measuring warhead volume, can solve the problems of warhead corrosion, difficulty in cleaning, inaccurate measurement, etc., and achieve the effects of reducing manual labor, wide application, and simple testing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

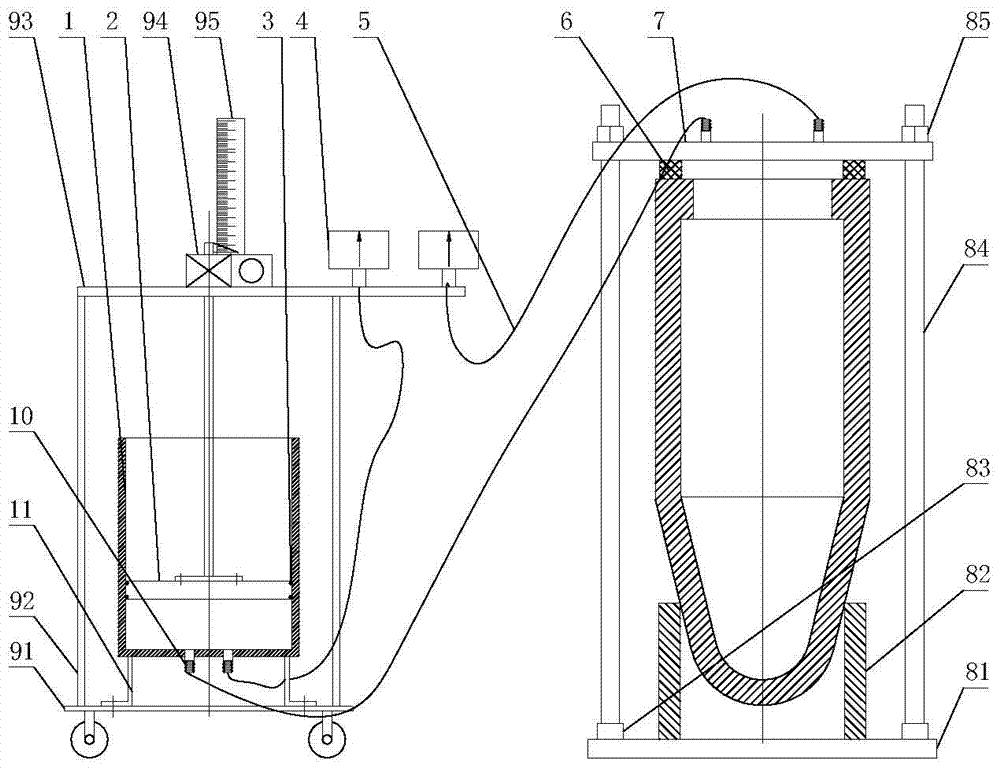

[0022] The present invention refers to the appendix figure 1 , attached figure 2 implement.

[0023] 1.1 Manufacture of the present invention

[0024] The metal parts of the present invention are all made of 0Cr18Ni9 stainless steel or hard aluminum metal materials. The constant volume cylinder 1 is made of a thick-walled cylinder with a bottom, and two pagoda-shaped vents 10 are sealed and welded at the bottom; the piston 2 is made of a short cylinder, and the outer surface is engraved with two circumferential grooves, and the upper plane is Make 2 threaded blind holes; choose rubber standard parts for sealing ring 3, digital pressure gauge for pressure gauge 4, high-pressure air pipe or hydraulic hose for air guide 5, and food-grade thick rubber plate for sealing plate 6. Open 2 through holes; the pressure plate 7 is made into a round cake with a thickness of 10mm-20mm, 2 through holes are opened in the middle of the round cake, each through hole is sealed and welded wit...

Embodiment 2

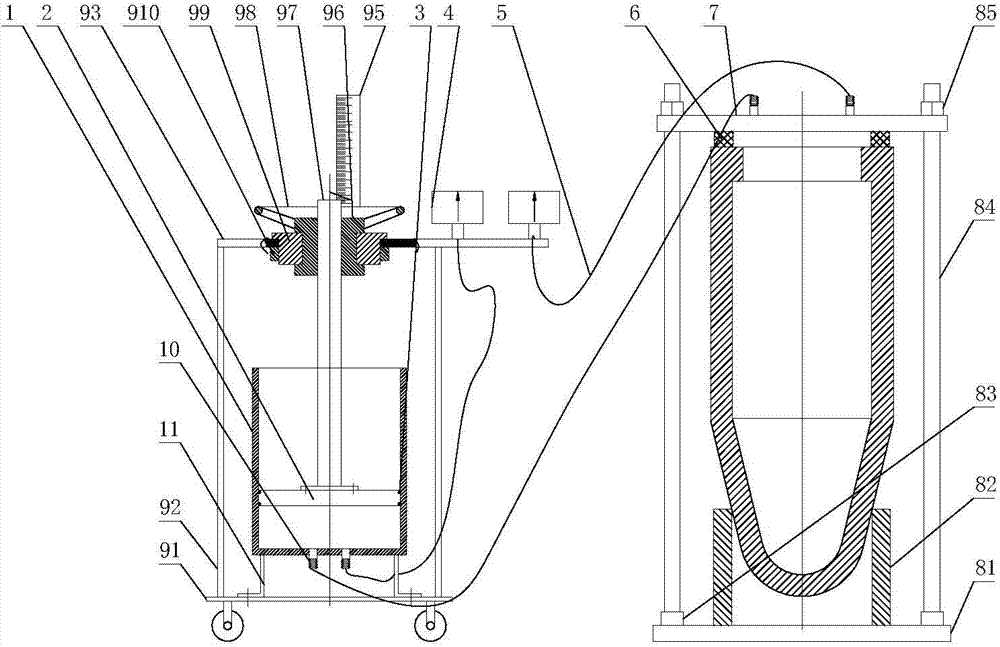

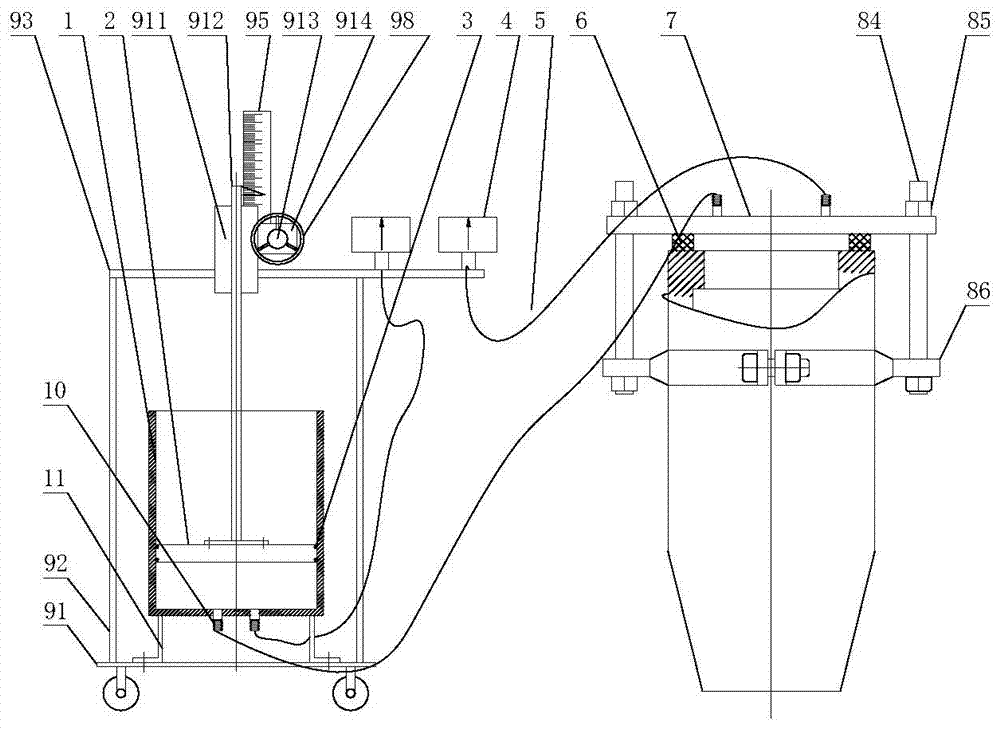

[0030] The present invention refers to the appendix figure 1 , attached image 3 , attached Figure 4 , attached Figure 5 implement.

[0031] 2.1 Manufacture of the present invention

[0032] The manufacturing method of the present invention is basically the same as that of Embodiment 1, except that the force applying lifting mechanism and the fixing seat are different: the fixing seat of the present invention is a fixing seat with a tightening ring 86; the force applying lifting mechanism of the present invention is a gear tooth The bar mechanism includes a guide sleeve 911, a cylindrical rack 912, a gear shaft 913, a gear seat 914, a hand wheel 98, etc.; Through holes are formed on the folded edge, the inner diameter of the hoop is the same as the outer diameter of the port section of the warhead, a shoulder is formed on the outer circumference, and 4 through holes are formed on the shoulder; the guide sleeve 911 is formed into a cuboid, along the length direction (axia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com