Method for determining degeneration rate of aircraft engine according to vibration signal

An aircraft engine and vibration signal technology, which is used in engine testing, machine/structural component testing, measuring devices, etc., can solve problems such as low accuracy of degradation curves and complex engine degradation, and achieve strong reliability and curve accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

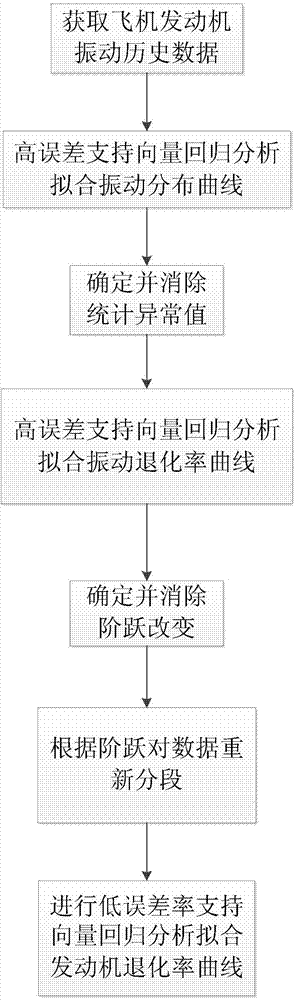

[0042] Describe the present invention below in conjunction with specific embodiment:

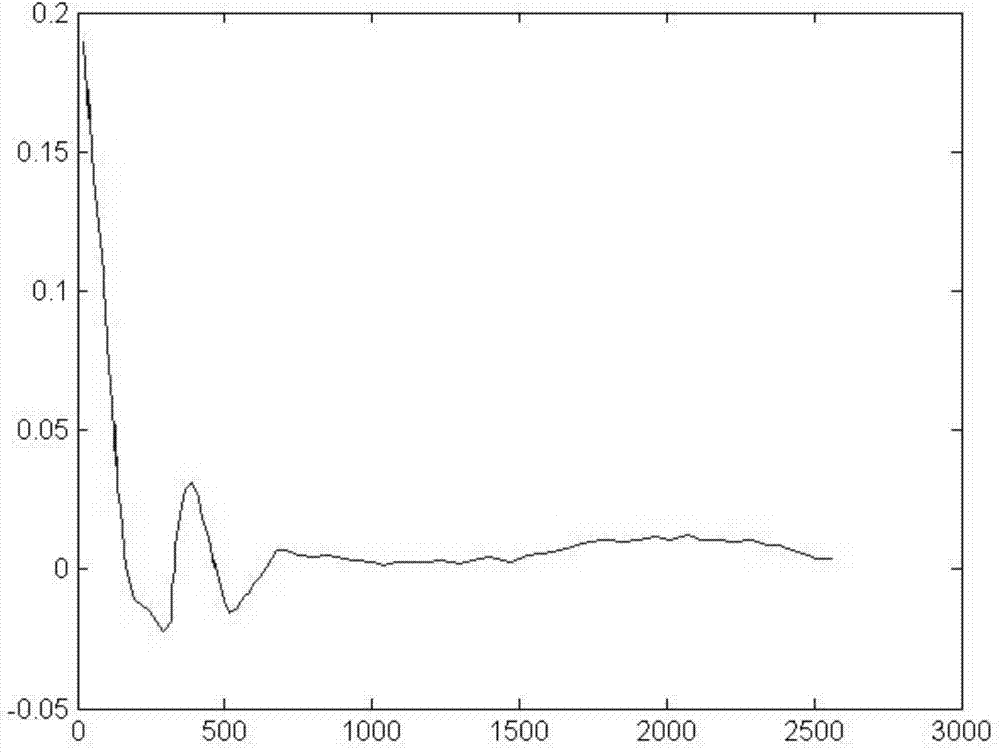

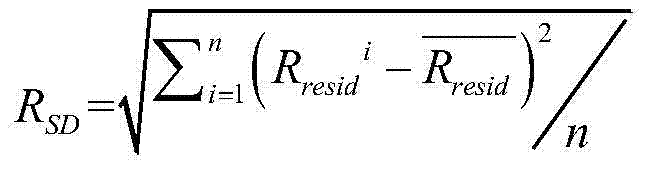

[0043]The present invention is suitable for determining the degradation performance of various types of aircraft engines. The required system includes several sensors for sensing engine vibration values, and can also directly use the historical data provided by each engine's own monitoring system. The key to this method is to confirm and eliminate engine vibration Statistical outliers and step change points in the value data to obtain accurate rate of change of engine vibration values. The method includes two test processes, one is to determine and eliminate the statistical abnormal points in the collected vibration value data; the other is to determine and eliminate the step change points in the degradation rate curve of the engine vibration value data. Eliminate the above two kinds of noise data through these two tests, and then use the low error rate support vector regression method to re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com