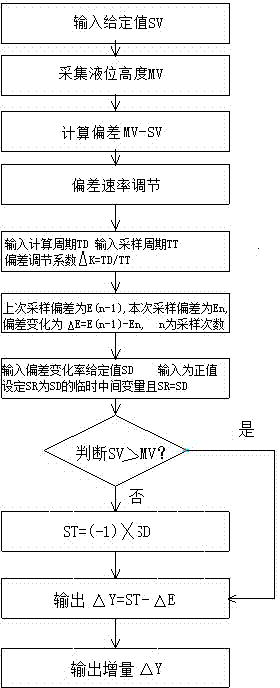

Control method with deviation rate adjustment function

A rate adjustment and rate technology, applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve the problems of inaccurate adjustment accuracy, unstable product quality, and oscillation of the adjustment loop, and achieve precise adjustment control, Avoid production erratic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

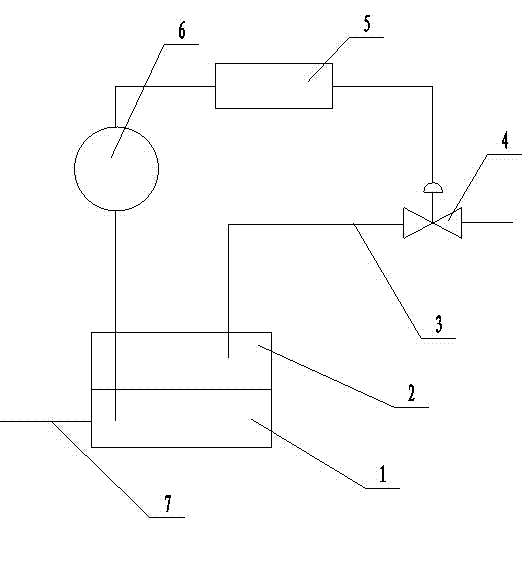

[0016] figure 1 As shown, the present invention is composed of a laser liquid level sensor, a PLC, and a pneumatic control valve. The input of the pneumatic control valve is connected to the output of the PLC, the input of the PLC is connected to the output of the laser liquid level sensor, and the input of the laser liquid level sensor is connected to the flotation device. The slurry outlet and the output of the pneumatic regulating valve are connected to the inlet.

[0017] The PLC uses Siemens 417 system.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com