Multistage surface turning device

A technology of wagon and installation position, which is applied in the direction of auxiliary devices, turning equipment, turning equipment, etc., can solve the problems of easy damage, high maintenance cost, and low production efficiency of CNC lathes, and achieve production cost savings, convenient and fast operation, and high production efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

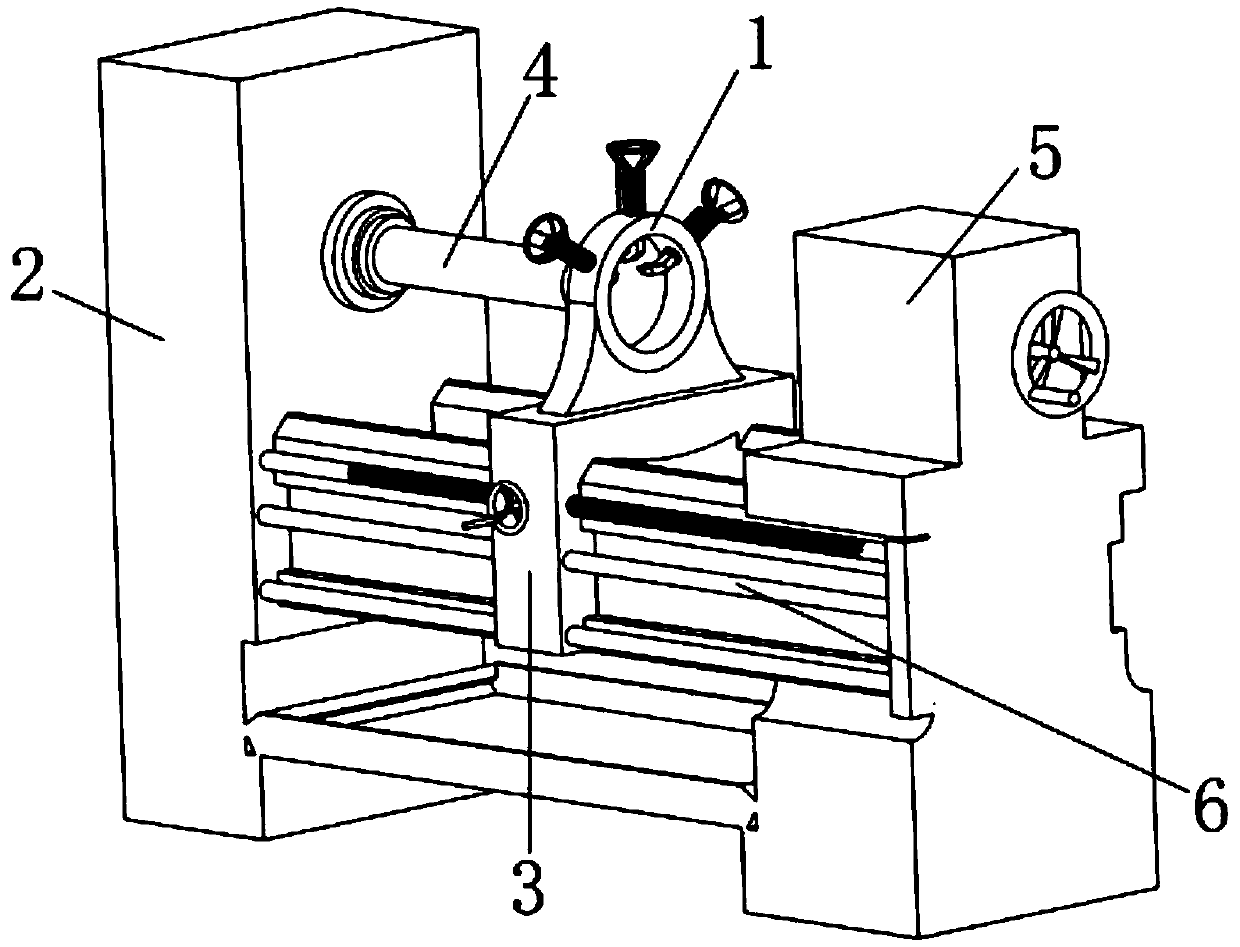

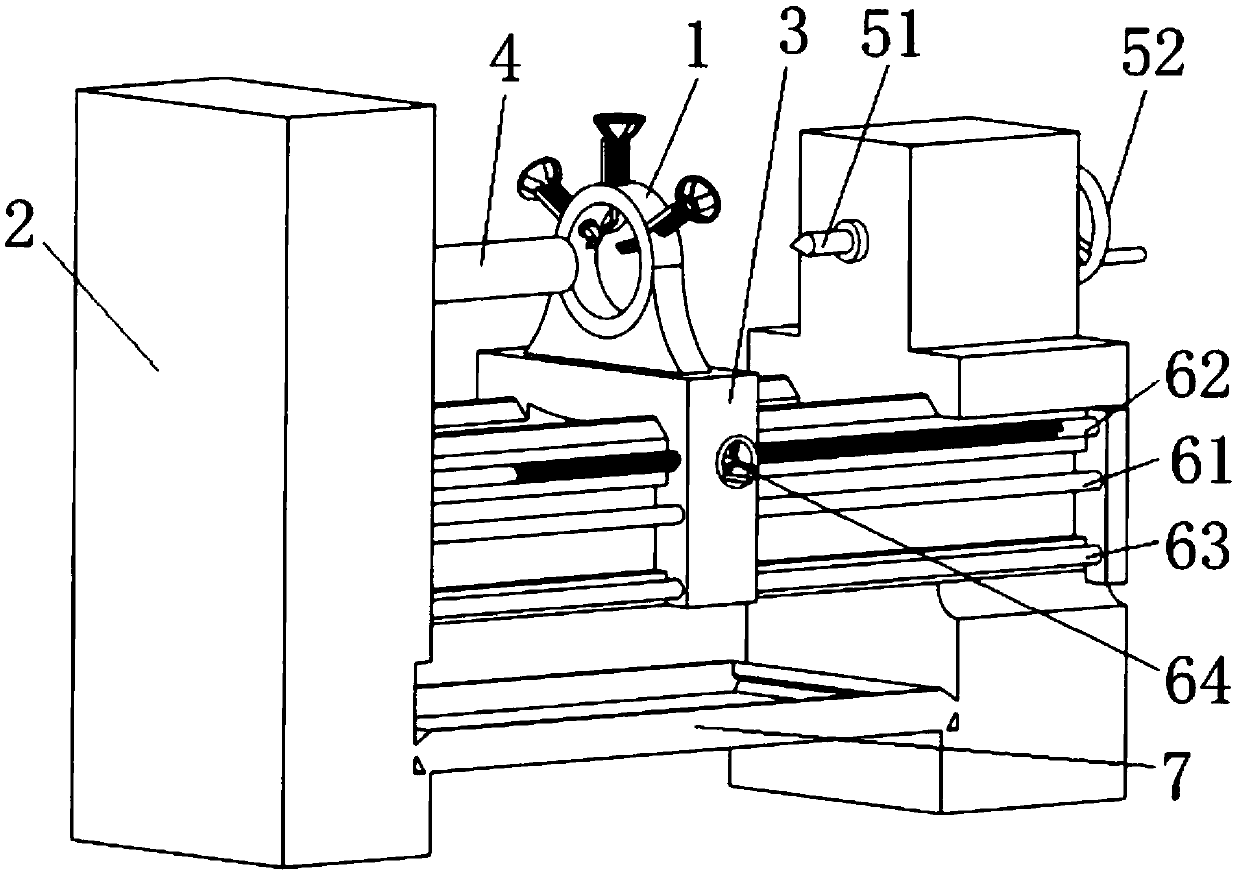

[0034] like Figure 1-3 As shown, a multi-stage turning device includes a tool 1, a bed body 2 for installing the tool 1, a tool connector 3 connected to the tool 1, and a workpiece 4 fixed on the bed body 2. . A tailstock 5 for supporting the workpiece 4 in cooperation with the bed body 2 and a driving mechanism 6 for driving the tool 1 to move;

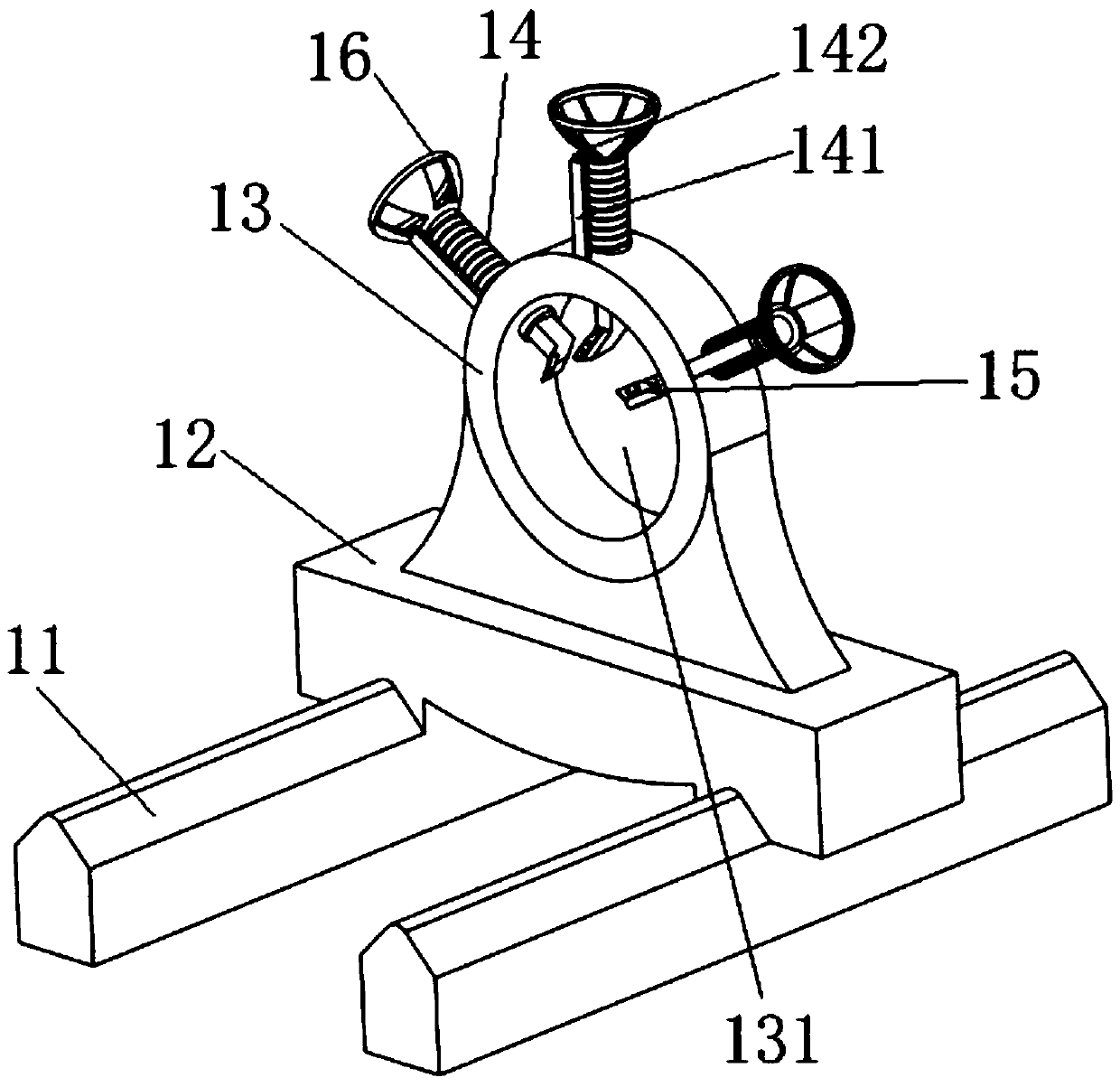

[0035] like image 3 As shown, the tool 1 includes a guide rail 11, a support 12 that is located on the guide rail 11 and can slide along the guide rail 11, a tool holder 13 mounted on the support 12, at least two The adjustment mechanism 14 on the knife rest 13 and the knife body 15 located at the end of the adjustment mechanism 14;

[0036] The tool holder 13 is annular, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com