Calibration method of gasoline engine particulate matter model under low-temperature environment

A low-temperature environment and calibration method technology, applied to mechanical equipment, engine components, combustion engines, etc., can solve problems such as high cost and long time consumption, and achieve the effects of improving service life, reducing development costs, and fast and effective model matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

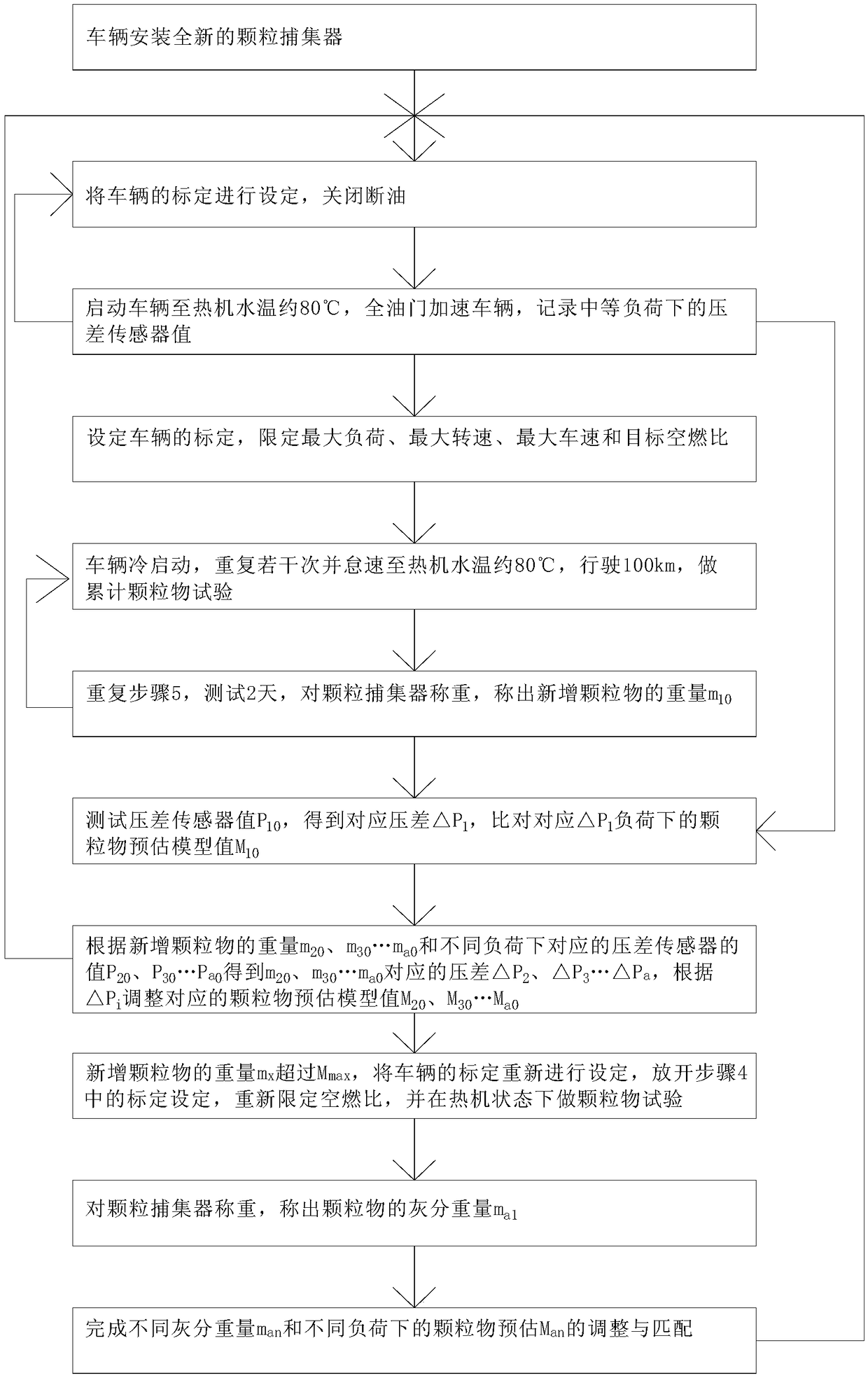

[0030] Please see attached figure 1 , a method for calibrating a gasoline engine particulate matter model in a low-temperature environment, comprising the following steps:

[0031] Step 1: Replace the vehicle with a brand new particle filter;

[0032] Step 2: Set the calibration of the vehicle and turn off the fuel cut-off.

[0033] Step 3: Start the vehicle until the engine water temperature is about 80°C, accelerate the vehicle at full throttle, and record the value P of the differential pressure sensor under a certain medium load a0 . The medium load is about 600~900Kpa.

[0034] Step 4: Carry out related settings on the calibration of the vehicle to limit the maximum load, maximum speed, maximum vehicle speed and target air-fuel ratio.

[0035] In step 4, the maximum load limit is about 400~500Kpa, the maximum speed limit is about 2000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com