Method of joining clad metal member and metal part, method of manufacturing thermal tripping device, and circuit breaker

A technology for metal parts and tripping devices, which is used in the manufacture of emergency protection devices, circuit breaker parts, circuits, etc., can solve the problems of insufficient bonding strength, heat dispersion, and applied heat, and achieve the effect of suppressing scattering and sufficient bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

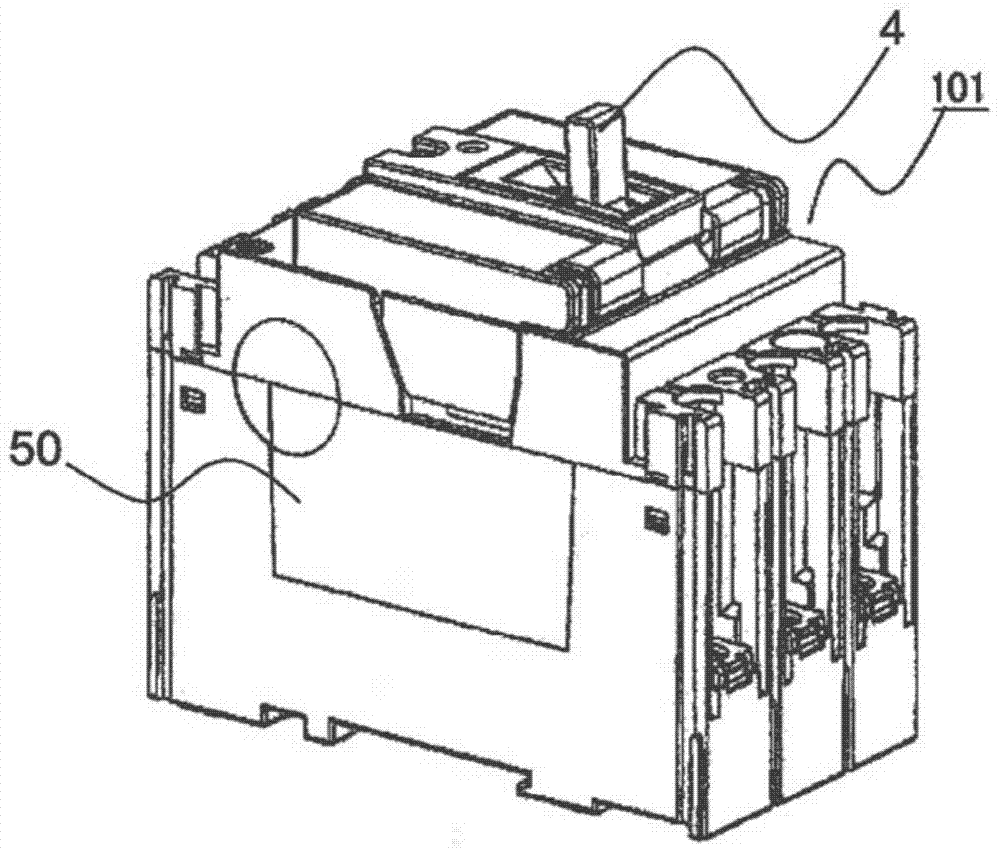

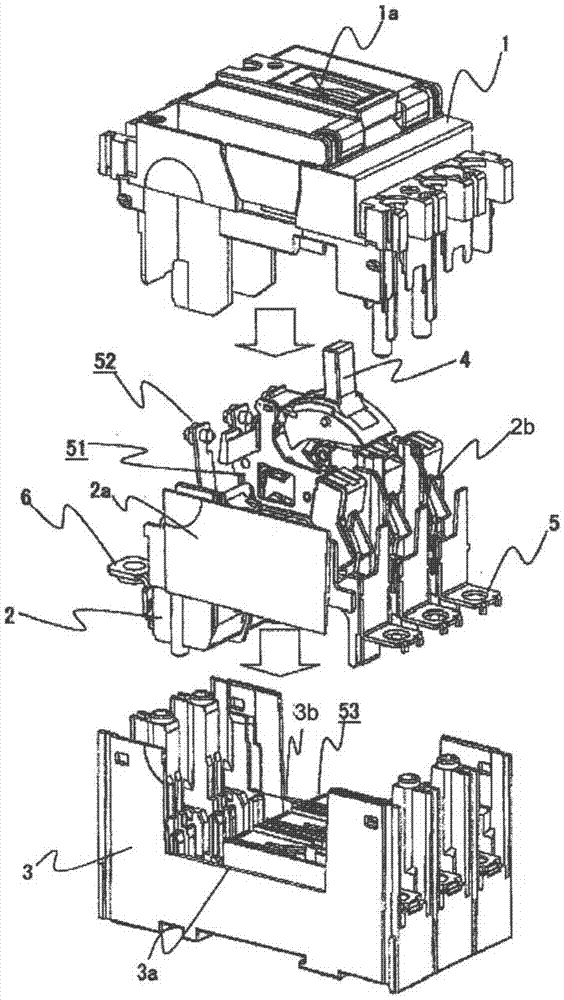

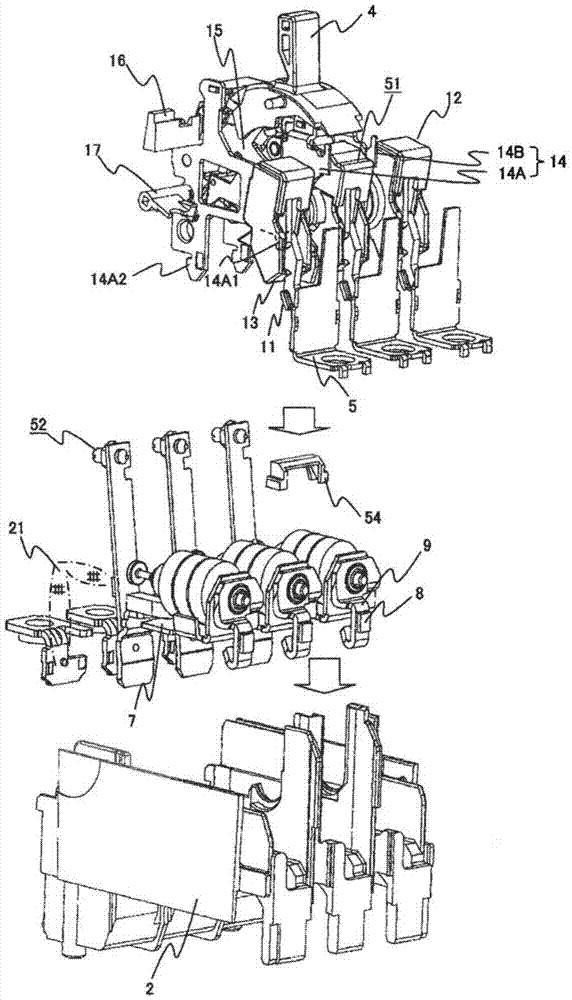

[0034] figure 1 It is an external perspective view showing the circuit breaker in Embodiment 1 of this invention. in addition, figure 2 is said to be figure 1 The shown perspective view of the appearance of the circuit breaker is sequentially decomposed into a cover, an intermediate base, and a perspective view of the state of the base from above. image 3 is to figure 2 The shown is a perspective view of the components contained in the middle base. in addition, Figure 4 It is a perspective view showing a single-pole overcurrent tripping device and a yoke. in addition, Figure 5 It is an enlarged perspective view showing a state in which an insulating member is attached to the overcurrent tripping device of the central pole.

[0035] exist figure 1 as well as figure 2 Among them, the insulating frame 50 of the circuit breaker 101 for 3 poles is constituted by the cover 1 , the intermediate base 2 and the base 3 . Among them, the intermediate base 2 accommodates t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com