Forming mold of an adjustable wave support ring and its combined mold

A technology for forming molds and support rings, applied in the field of tooling fixtures, can solve the problems of poor economic benefits, inability to process corrugated support rings, waste of manpower and material resources, etc., and achieve the effects of improving the forming effect, simple structure and good forming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

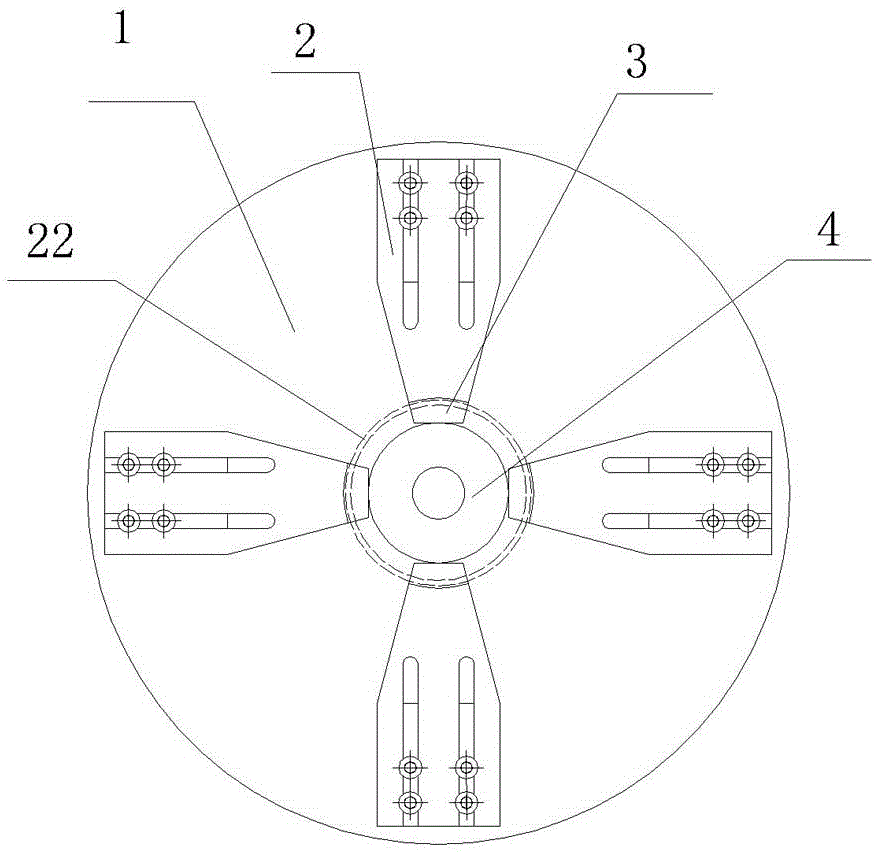

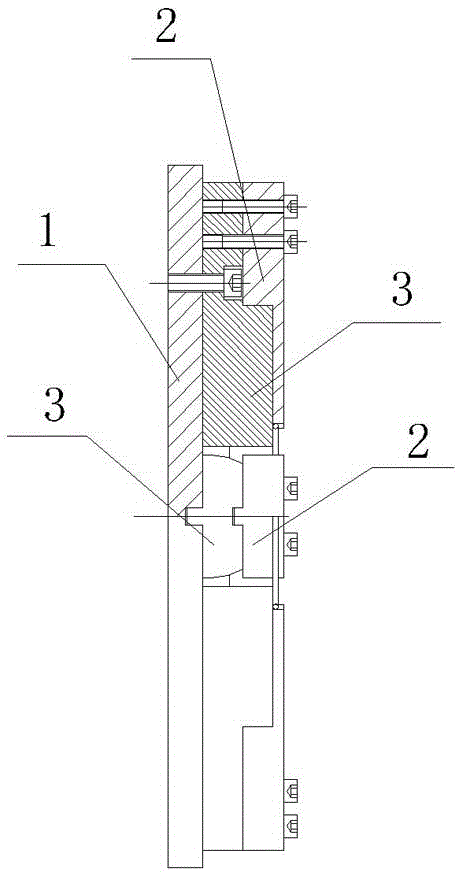

[0027] like figure 1 and 2 As shown, a molding die for an adjustable wave support ring includes a chassis 1 on which four molding heads 3 are evenly distributed, and a positioning baffle 2 is installed on each molding head 3 . The upper surface of the forming indenter 3 is an arc-shaped pressing surface, and the radian of the arc-shaped pressing surface is consistent with the wave radian of the supporting ring 22 to be formed. The front end surface of the positioning baffle 2 is an inwardly concave arc surface, and the arc of the arc surface is consistent with the arc of the supporting ring 22 to be formed. When in use, the flat support ring is placed on the forming pressure head, and the flat support ring is positioned through the positioning baffle.

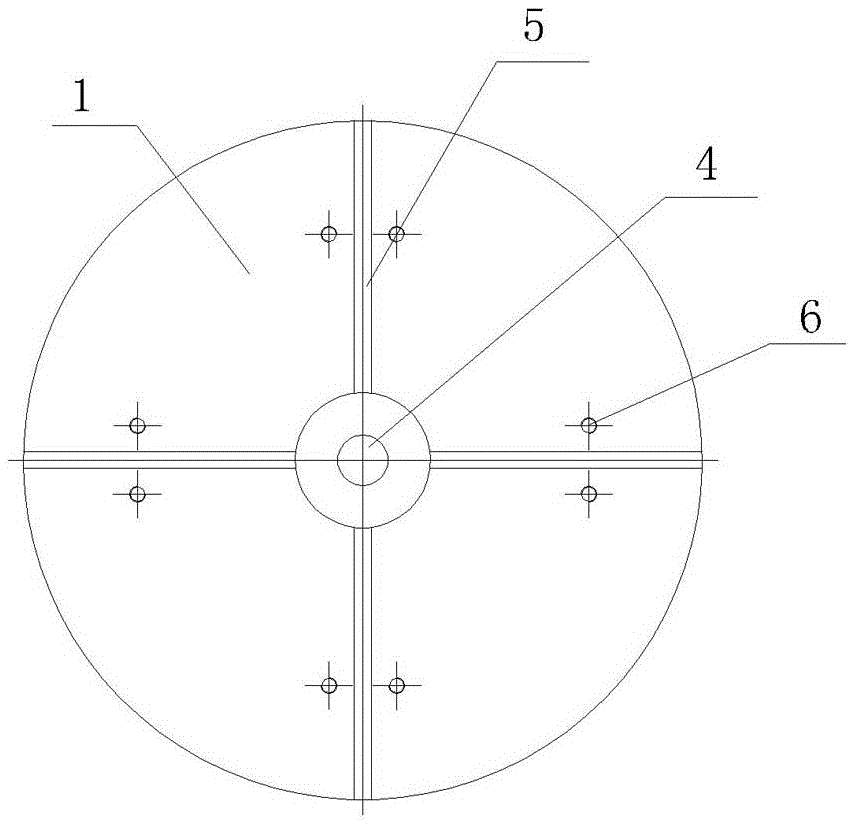

[0028] like image 3 As shown, the center of the chassis 1 is provided with a stepped positioning hole 4, with the positioning hole 4 as the center, four guide grooves 5 are evenly distributed on the chassis, and one end of ...

Embodiment 2

[0033] like Figure 10 and 11 Shown in and 12, a molding composite mold of an adjustable wave support ring includes an upper chassis 24 and a lower chassis 23, and the structure of the upper chassis 24 and the lower chassis 23 is as the chassis structure in embodiment 1. Both the upper chassis 24 and the lower chassis 23 are mounted on the press. When working, first put the stepped central column 21 into the lower chassis, and then position the upper chassis through the central column 21 to realize the concentricity of the upper and lower chassis. Then the flat support ring is fixed on the forming indenter through the positioning baffle, and the forming indenter 20 of the upper chassis and the forming indenter 19 of the lower chassis are staggered by 45° during installation, so as to ensure the even distribution of the crests and troughs of the wave form. sine wave. When the upper chassis and the lower chassis of the starting press are closed, the flat support ring is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com