Solar cell panel transportation support device

A solar panel and bracket device technology, which is applied in the direction of transportation and packaging, packaging, external frames, etc., can solve the problems that affect the normal production of components, the physical injury of employees, glass bursting, etc., so as to avoid bending and improve the yield rate , to avoid the effect of bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

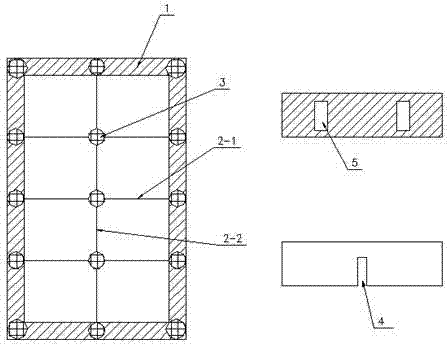

[0012] like figure 1 As shown, the device is made up of frame 1, cross beam 2-1, vertical beam 2-2 and spacer 3, wherein frame 1 is a square aluminum alloy tube with small hole 5 in the middle; cross beam 2-1 And the vertical support beam 2-2 is an aluminum alloy sheet with openings 4-1 and 4-2 in the middle. When assembling, the horizontal support beam 2-1 is on the top, and the vertical support beam 2-2 is on the bottom, and at the opening 4-1 and 4-2 Insertion; after the insertion is completed, the mat 3 is adhered between the beam and the frame and between the beam and the beam. Direct collision effectively protects components.

[0013] The sequence of assembly of the device is as follows: first, the horizontal beam 2-1 and the vertical beam 2-2 are plugged together at the opening. Insert the support beams to the frame again. Finally, stick a hard polyurethane ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com