A visible-infrared compatible cloaking device and its preparation method

An infrared and encapsulation layer technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as insufficient visible light stealth ability, and achieve the effect of visible-infrared compatible stealth performance improvement and stealth ability improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

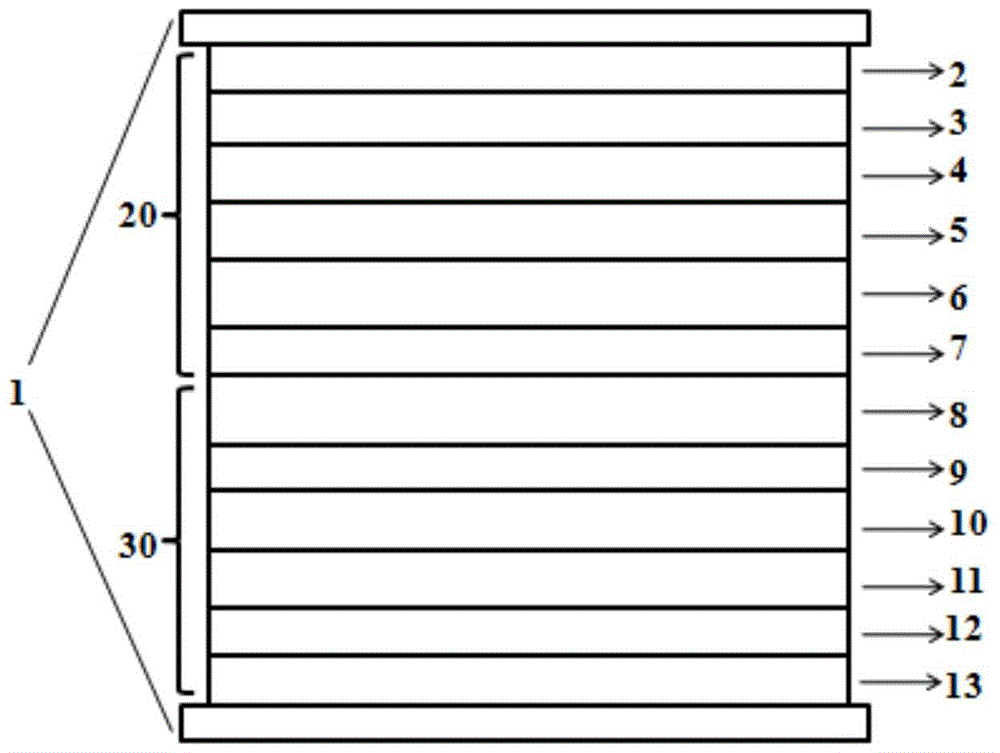

[0040] A visible-infrared compatible cloaking device, such as figure 1 . From top to bottom are the infrared transparent encapsulation layer 1, the first flexible transparent substrate 2, the first transparent electrode 3, the active color-changing material layer 4, the porous membrane carrier 5 adsorbed with polyelectrolyte, the ion storage layer 6, and the second transparent electrode 7. The second flexible transparent substrate 8 , the third transparent electrode 9 , the porous membrane carrier 10 adsorbed with electrolyte, the photonic crystal layer 11 , the metal electrode layer 12 , the flexible substrate material 13 , and the infrared transparent encapsulation layer 1 . The electrochromic device 20 is composed of a first flexible transparent substrate 2 , a first transparent electrode 3 , an active color-changing material layer 4 , a porous membrane carrier 5 adsorbed with polyelectrolyte, an ion storage layer 6 and a second transparent electrode 7 . The photonic cryst...

specific Embodiment approach 2

[0052] A visible-infrared compatible cloaking device, such as figure 1 . Adopting a 13-layer laminated structure, from top to bottom are the infrared transparent encapsulation layer 1, the first flexible transparent substrate 2, the first transparent electrode 3, the active color-changing material 4, the porous membrane carrier 5 adsorbed with polyelectrolyte, and the ion storage layer 6 , second transparent electrode 7, second flexible transparent substrate 8, third transparent electrode 9, porous film carrier 10 adsorbed with polyelectrolyte, photonic crystal layer 11, metal electrode layer 12, flexible substrate material 13, infrared transparent encapsulation layer 1. The electrochromic device 14 is composed of the first flexible transparent substrate 2, the first transparent electrode 3, the active color-changing material 4, the porous membrane carrier 5, the ion storage layer 6 and the second transparent electrode 7, and the second flexible transparent substrate 8, the f...

specific Embodiment approach 3

[0064] A method for assembling a visible-infrared compatible cloaking device, comprising the steps of:

[0065] (1) Deposit metal electrode layer 12 on flexible substrate material 13: adopt methods such as thermal evaporation or ion sputtering to form thickness at the thick silver metal layer of 50nm as metal electrode on flexible substrate material 13 surface;

[0066] (2) Preparation of photonic crystal layer 11: prepare photonic crystal layer 11 on the metal electrode layer 12 that step (1) obtains, wherein photonic crystal can grow opal structure silicon dioxide photonic crystal in silicon dioxide microsphere emulsion, Then fill polyferrocenesilane to obtain;

[0067] (3) Preparation of porous membrane carrier 10 with adsorbed electrolyte: after dissolving lithium hexafluorophosphate at a concentration of 0.1 mol / L in glutaronitrile, immerse the porous film in the polyelectrolyte solution to form porous membrane carrier 10 with adsorbed polyelectrolyte;

[0068] (4) Depos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com