A nozzle for preparing nanofibers and equipment thereof

A technology of nanofibers and nozzles, applied in fiber processing, textiles and papermaking, filament/wire forming, etc., can solve problems such as corona discharge, reduce corona discharge phenomenon, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

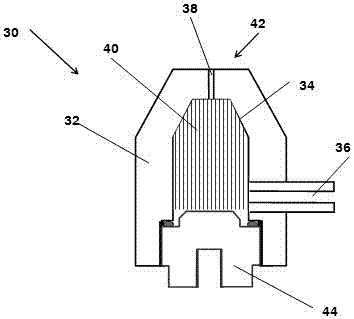

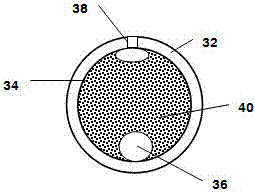

[0033] figure 2 is a schematic diagram of a nozzle 30 used in electrospinning to prepare fibers in Example 1. Nozzle 30 generally includes a sheath 32 and a cavity 34 .

[0034] The sheath 32 has a liquid inlet 36 through which the spinning liquid enters the cavity 34 . The sheath 32 also has a discharge outlet 38 through which liquid exits the cavity 34 .

[0035] The nozzle 30 also includes a buffer polarizer 40 placed in the middle of the cavity 34 , and the charge is efficiently transferred to the liquid in the cavity 34 through the polarizer during spinning. It is important that the structural size of the polarizer is such that the electrode specific surface area is at least 5 m2 / kg.

[0036] A suitable polarizer 40 has a large specific surface area for simple and rapid charge transfer into the liquid within cavity 34 . Polarizer construction types include: wires, meshes, grids, foams, sponges, cloths, braids, fins, parallel plates, bonded powder constructions, inter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com