Gripper assembly and lock/release method for a coiled tubing injector

A technology of oil pipe injection head and clamping device, which is applied in the direction of drilling equipment and methods, drilling pipes, casings, etc., to achieve the effects of cost and time saving, easy maintenance and replacement, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

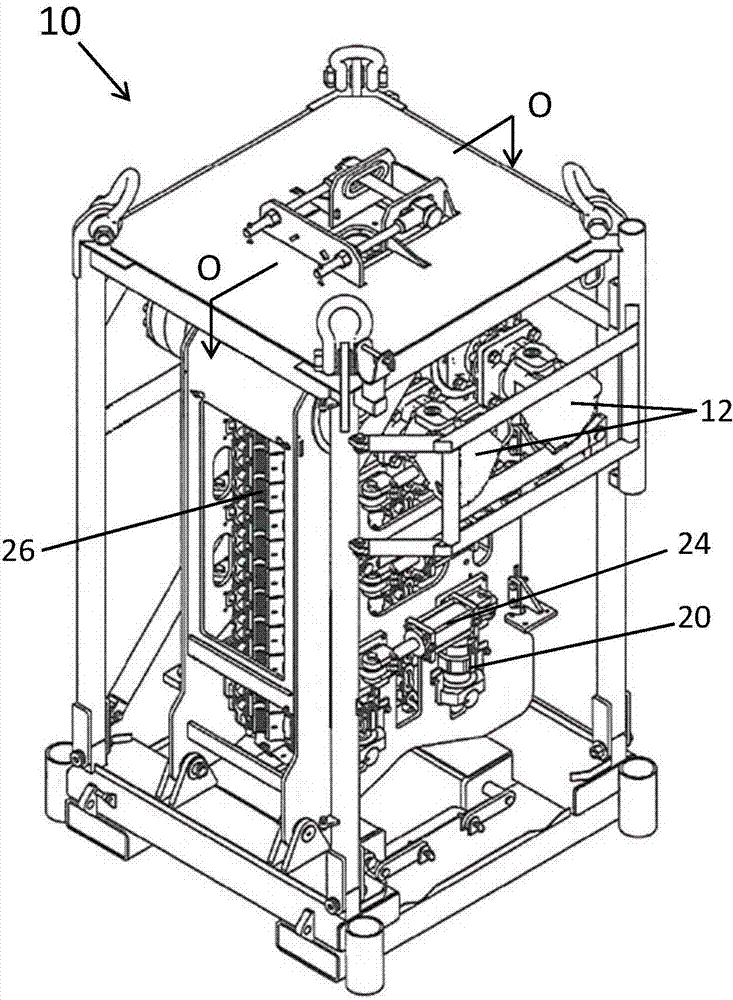

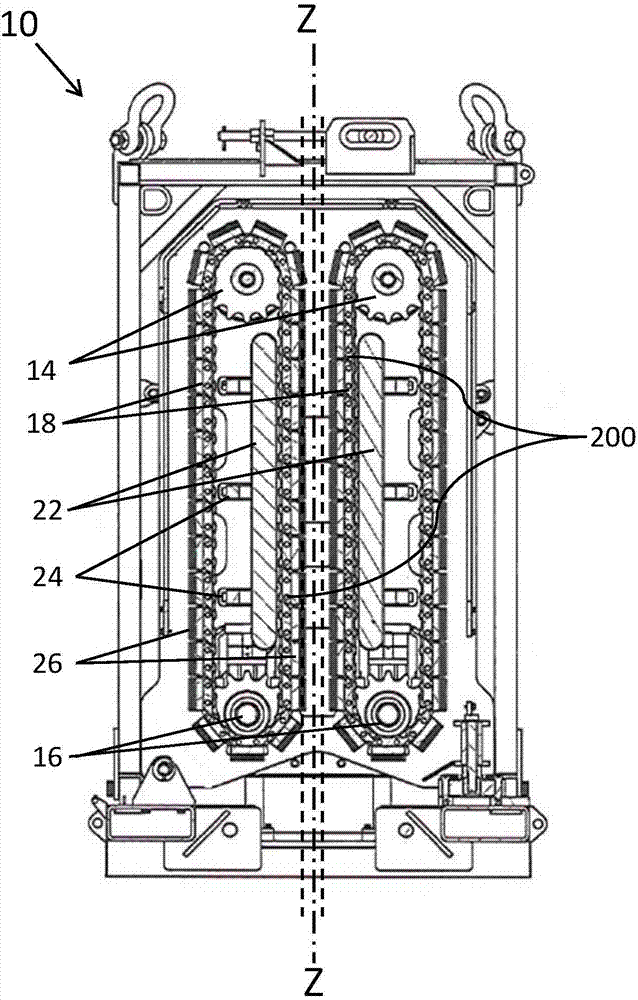

[0055] Attached below figure 2 Turning to FIG. 14 , a first embodiment of a gripping device for a typical coiled tubing injection head is shown, which is used to engage and grip coiled tubing for delivering or withdrawing a continuous length of coiled tubing into a well. like Figure 1B and 2 As shown, a plurality of clamping devices 100 , 100 . Each clamping device 100 is driven by a corresponding chain 200 and together with another opposing clamping device 100 driven by a corresponding chain 200 clamps and encases the coiled tubing therein.

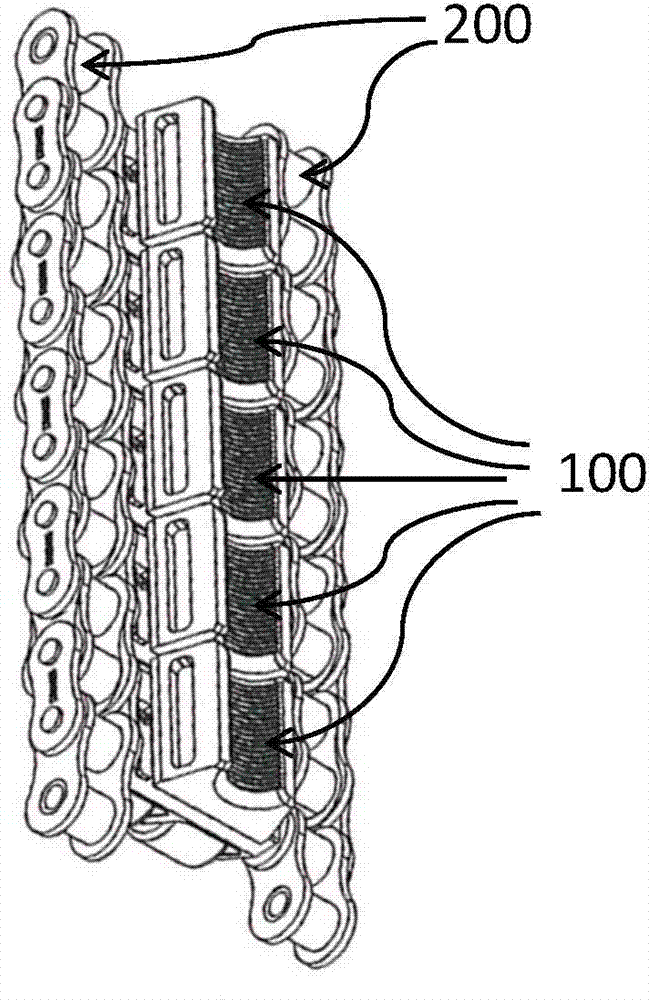

[0056] figure 2 A linear section of a conventional endless chain 200 with a gripping device 100 installed is shown in . see image 3 , a separate holding device 100 and its associated elements are mounted on the chain 200 . Chain 200 generally includes an inner chain plate 202 , an outer chain plate 204 , pins 206 and chain rollers 208 .

[0057] like Figure 4 As shown, in the first embodiment, the clamping device 100 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com