Anti-revolving automobile bolt and processing technique thereof

An anti-rotation, automotive technology, applied in the direction of screws, threaded fasteners, connecting components, etc., can solve the problems of high product scrap rate, high processing cost, wear and tear of hub arc surface, etc., to improve product yield and production efficiency, The effect of reducing processing steps and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

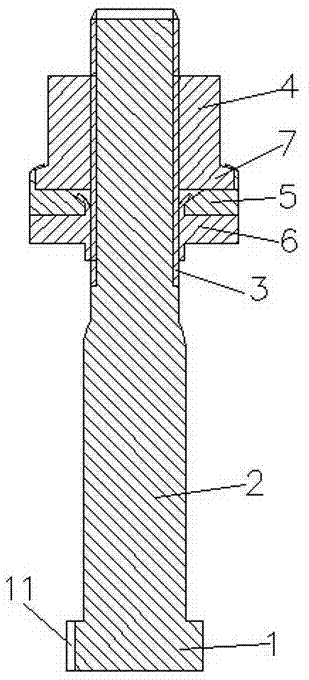

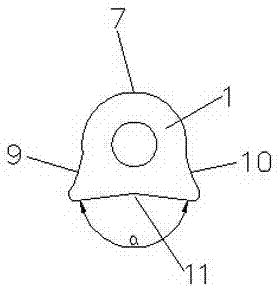

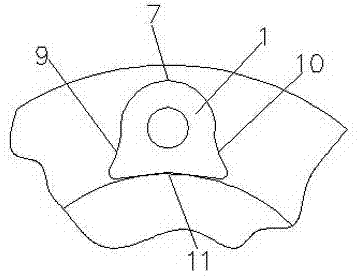

[0023] Please refer to the attached Figure 1 to Figure 3 As shown, the present invention is an anti-rotation automobile bolt, comprising a bolt head 1, a screw 2 formed by extending the bottom surface of the bolt head 1 downward, and a thread 3 formed on the outer edge of the screw, and the screw thread 3 is provided with a matching Nut 4, steel ring 5, flat washer 6, the nut 4 is provided with an integrally formed flange, the bolt head 1 is a flat columnar body, the upper end 7 of its cross section is narrower, the lower end 8 is wider, and the upper end 7 The distance between the bolt head 1 and the lower end 8 is an arc surface on the left side 9 and the right side 10, the lower end of the bolt head 1 is a stable surface 11 in contact with the hub, the upper end 7 is an arc surface, the lower end 8 is a con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com