Three-position lock-ring inertial synchronizer of amphibian vehicle

An amphibious and lock ring technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve problems such as not being suitable for design requirements, and achieve the effects of reducing production costs and maintenance costs, light weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

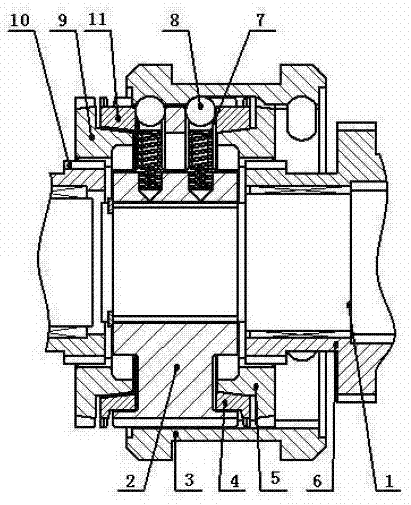

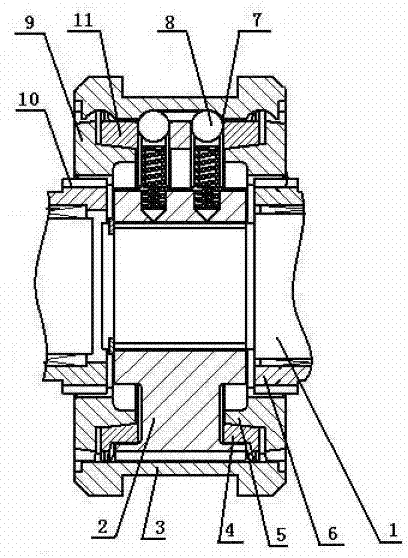

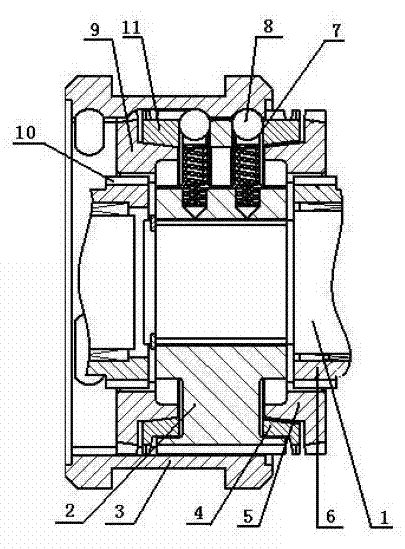

[0011] Embodiment, with reference to the accompanying drawings, a three-gear locking ring type inertia synchronizer for amphibious vehicles, including an input shaft 1, is characterized in that a spline hub 2 is installed on the input shaft 1 with a spline, and the spline hub 2 is right The side is equipped with gear shaft one 6 for driving the ship, and the left side is equipped with the gear shaft two 10 for driving the vehicle; between the right side of the spline hub 2 and the gear shaft one 6, the conical marine ring gear 5 and the conical surface dial are housed. Dynamic lock ring 1 4, between the left side of the spline hub 2 and the gear shaft 2 10, a tapered vehicle ring gear 9 is installed, and a tapered surface toggle lock ring 2 11 is installed on the tapered vehicle gear ring 9 An adapter sleeve 3 is movably installed on the outside of the conical surface marine gear ring 5, the conical surface toggle lock ring 1 4, the spline hub 2, the conical surface toggle lock...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap