Method for operating a coriolis mass flowmeter

A mass flow and Coriolis technology, applied in mass flow measurement devices, direct mass flow meters, measuring flow/mass flow, etc., can solve the problem that sensor-assisted methods and methods cannot detect, cannot install sensors, and cannot simply Describe issues such as the effect of temperature gradients on the sensitivity and zero point of Coriolis mass flow meters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

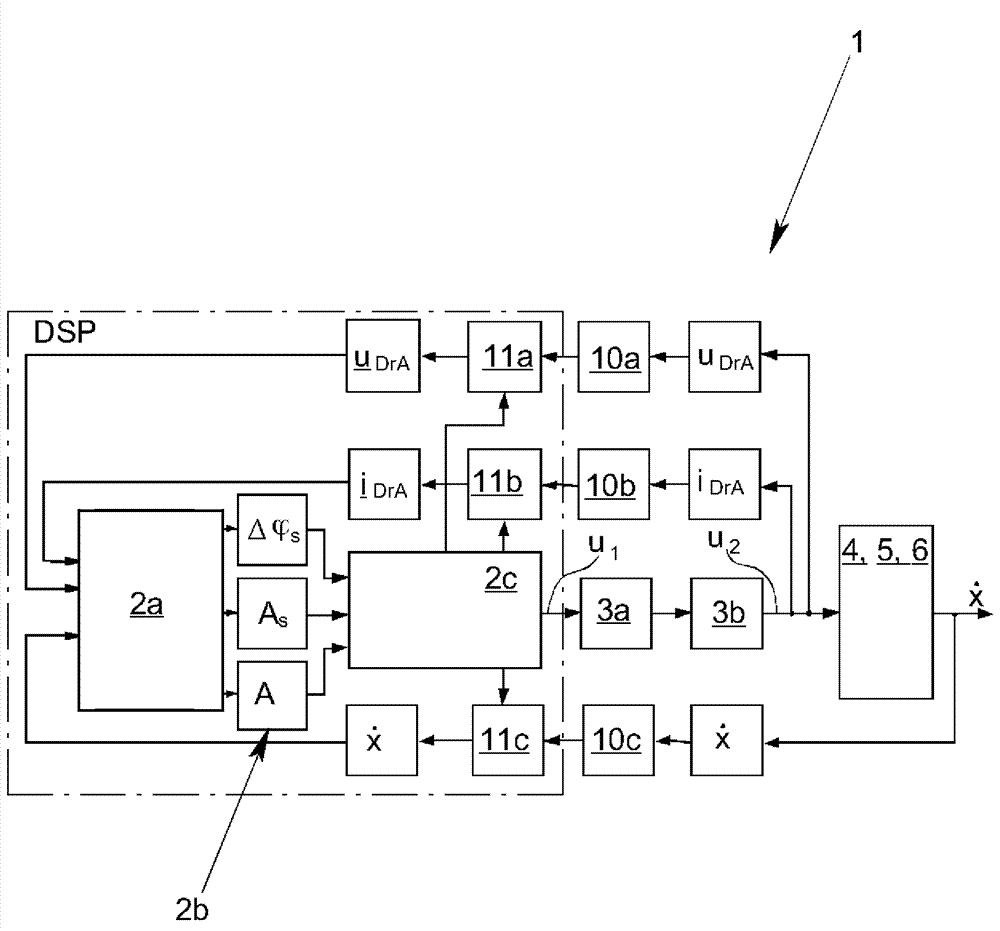

[0025] exist figure 1 1 first schematically shows a Coriolis mass flowmeter 1 with a regulator 2 implemented in a digital signal processor, an electrical servo 3 and an electrical drive 4 as a vibration generator. The electrical servo 3 generates an electrical excitation signal u for exciting the electrical drive 4 2 , wherein the electrical drive 4 excites the measuring tube 5 to vibrate in the first natural mode. The excited vibrations of the measuring tube 5 are detected by the vibration receiver 6 as a vibration measurement variable, wherein the measurement tube velocity is firstly detected as the vibration measurement variable . The temporal phase difference, ie the time offset (Zeitversatz) Δ, is then determined as a derived vibration measurement variable from the measuring tube velocities on the input and output sides. t .

[0026] exist figure 1 The Coriolis mass flowmeter 1 is shown in two parts. One half of the Coriolis mass flowmeter 1 actually forming a unit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com