A generation method of powder-coated sintered support structure for aircraft structural parts based on spatial lattice

A technology for aircraft structural parts and support structures, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve time-consuming and difficult problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] The implementation examples of the present invention will be described in detail below in conjunction with the accompanying drawings. This implementation example is carried out on the premise of the technical solution of the invention. This paper provides detailed implementation methods and specific implementation processes, but the protection scope of the present invention is not limited to the following implementation examples.

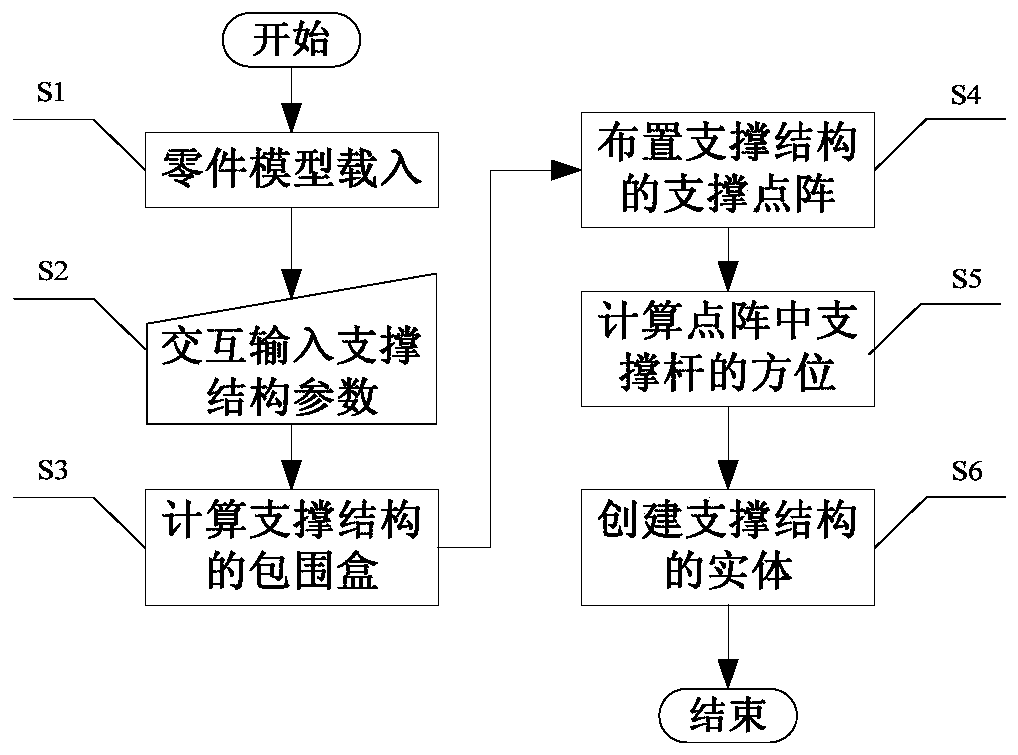

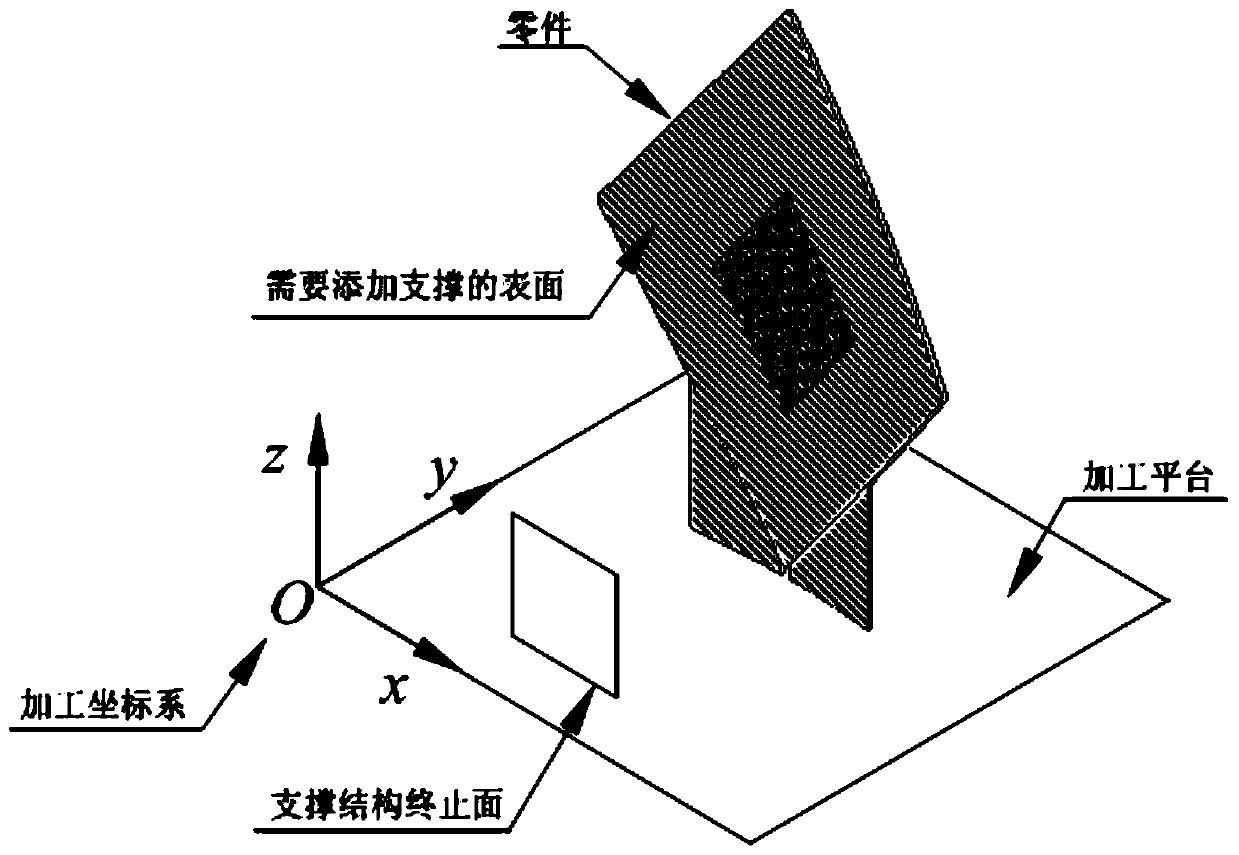

[0094] figure 1 Shown is the specific implementation flow of the support structure generation method proposed by the present invention, and its implementation steps are: 1) The overall flow of the method is: 1) Part model loading; 2) User interactive input of support structure parameters; 3) Calculation The bounding box of the support structure; 4) arrange the support lattice of the support structure in the general outline of the support structure; 5) calculate the orientation of the support rods in the lattice; 6) create the entity of the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com