Package Structure Of Light Emitting Diode

A technology for light-emitting diodes and packaging structures, applied in electrical components, electrical solid-state devices, circuits, etc., can solve problems such as damage, increase in electronic components, and shorten the service life of light-emitting diodes, and achieve the effect of improving heat dissipation efficiency and solving heat dissipation problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

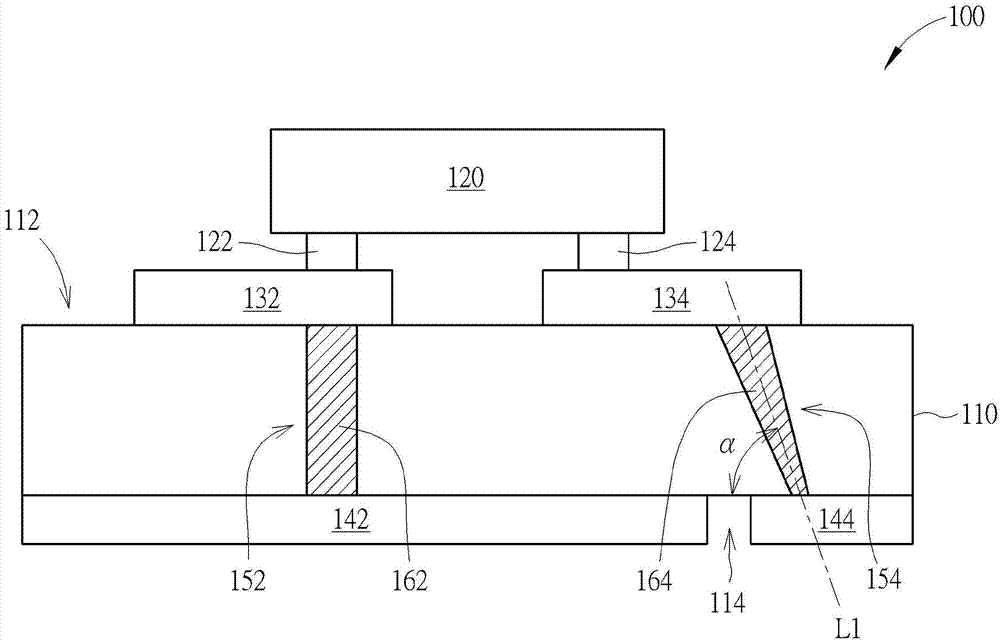

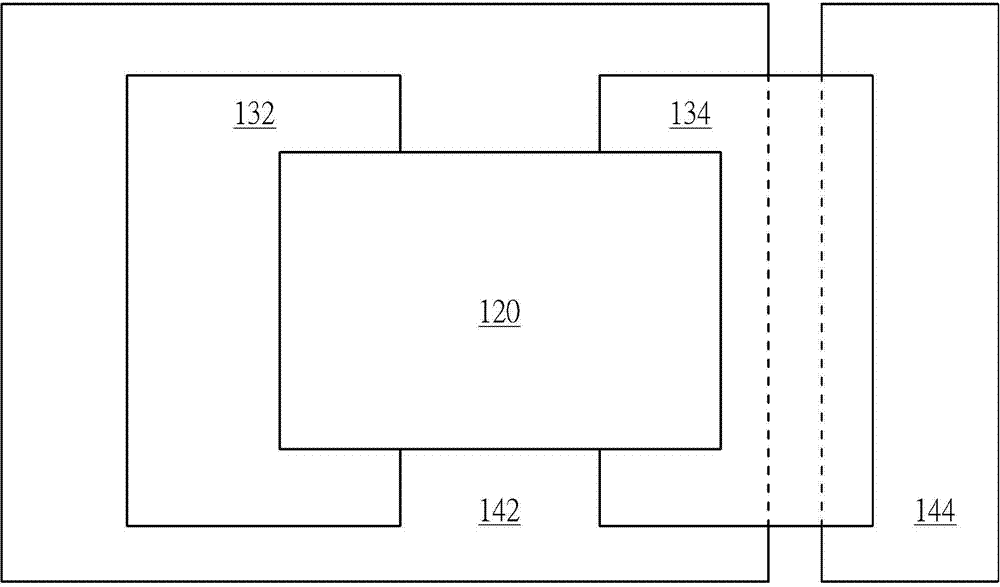

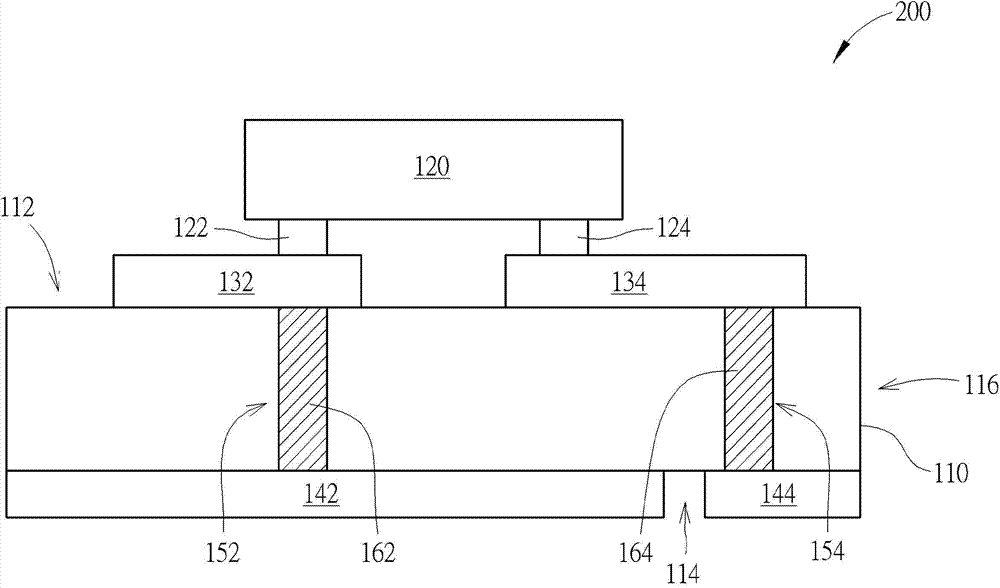

[0012] Please also refer to figure 1 and figure 2 . figure 1 It is a schematic diagram of the first embodiment of the package structure of the light emitting diode of the present invention. figure 2 It is a schematic diagram of the orthographic area configuration of related components of the light emitting diode packaging structure of the present invention on a substrate 110 . like figure 1 As shown, the LED packaging structure 100 of the present invention includes a substrate 110 and a LED die 120 . The substrate 110 has an opposite upper surface 112 and a lower surface 114 . The upper surface 112 of the substrate is provided with two upper metal pads 132 , 134 which are not conductive to each other. The lower surface 114 of the substrate is provided with two lower metal pads 142 , 144 which are not electrically connected to each other. The LED die 120 straddles the upper metal pads 132 , 134 . The LED chip 120 has a first electrode 122 and a second electrode 124 ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com