Tensioner

A tensioning device and control device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as non-rotation, single tensioning and positioning function, deformation of pipe workpieces, etc., to reduce deformation, Improve efficiency, avoid contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with the best embodiment shown in the accompanying drawings, it will be further described in detail.

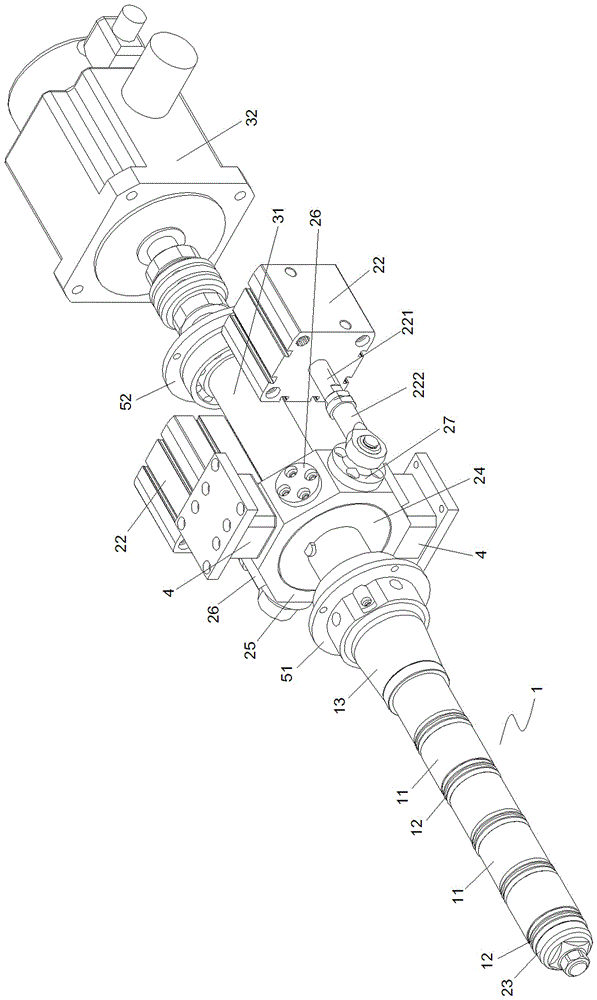

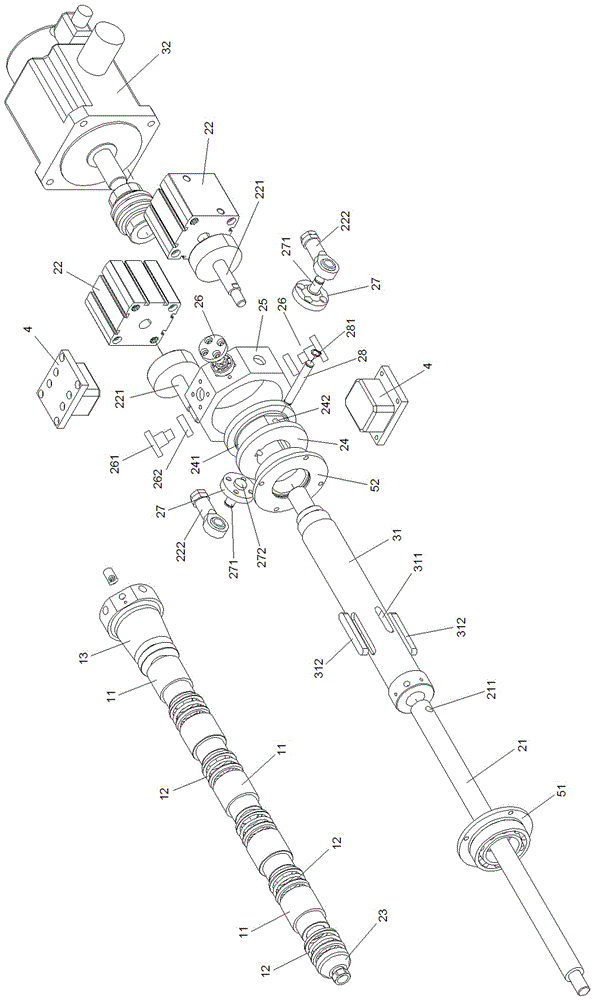

[0022] Such as figure 1 and figure 2 As shown, the tensioning device of the present invention mainly includes a support member 1 on which pipe workpieces are sleeved and a control device, and the control device further includes a tensioning mechanism and a rotating mechanism. They are described below.

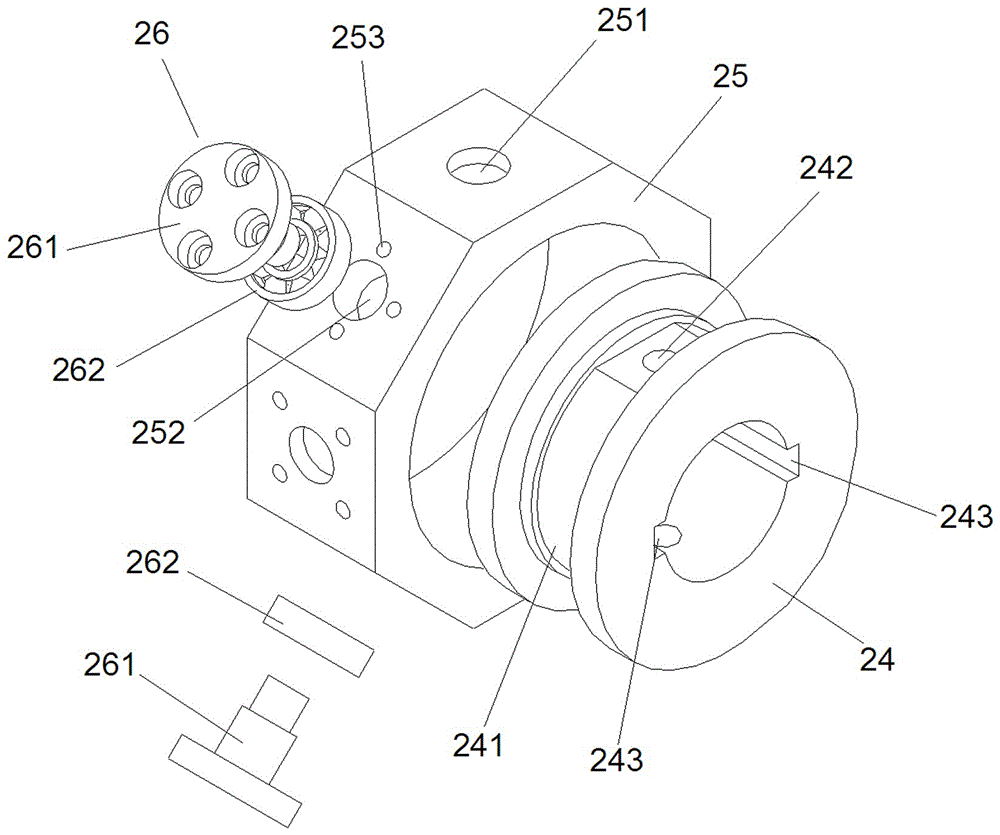

[0023] The support member 1 is roughly columnar and includes a plurality of expansion sleeves 11 connected front and rear, rubber rings 12 sandwiched between adjacent expansion sleeves 11 and an expansion sleeve seat 13 fixed to the rearmost expansion sleeve 11 . Such as Figure 4 As shown, the outer diameter of the front part of the expansion sleeve 11 is smaller, and the outer diameter of the rear part is larger, and a vertical step 113 is formed at the junction of the front and rear parts. When assembling, the front part of the rear expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com