Method and device for sorting tobacco leaves through hairbrush rollers

A brush roller and sorting device technology, which is applied in the field of machinery, can solve the problems of labor-consuming, low work efficiency, and high labor intensity, and achieve the effects of reducing labor intensity, ideal use effect, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

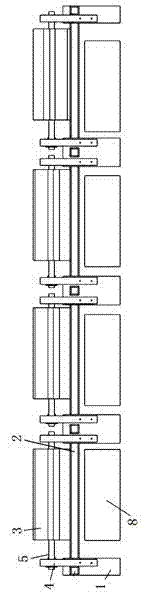

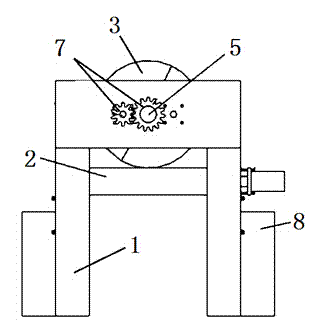

[0014] Embodiment 1 of the present invention: the method of sorting tobacco leaves by using a brush roller, a brush roller is set above the conveyor belt, and the graded tobacco leaves are transported by the conveyor belt, and after the tobacco leaves are transported to the designated brush roller, The brush roller is controlled by the motor to rotate forward or reversely, so that the tobacco leaves on the conveyor belt are brushed into the tobacco leaf collection boxes on both sides of the conveyor belt to realize automatic tobacco leaf grading and sorting, so as to improve the sorting efficiency of tobacco leaves.

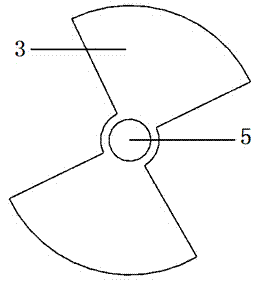

[0015] The structure of the tobacco leaf sorting device is shown in the figure, including a support 1 provided with a conveyor belt 2, and three evenly distributed brush drums 3 are arranged above the conveyor belt 2, and the brush drum 3 is provided with symmetrical concave holes on the surface. The hollow drum of the groove, the axial direction of the brush drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com