Metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

A technology of sealing strips and composite panels, applied in climate change adaptation, insulation improvement, building components, etc., can solve problems such as thermal insulation performance not reaching the best state, cold bridge, etc., to save manpower and time, avoid damage, and save material effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

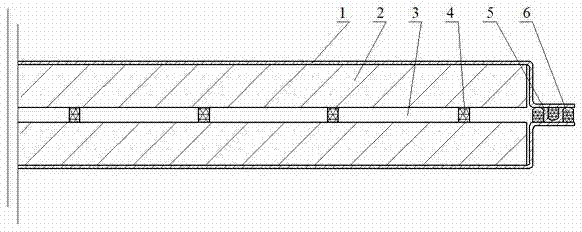

[0035] Example: see figure 1 , the metal vacuum composite panel with sealing strip edge sealing is composed of shell 1, core plate 2, vacuum chamber 3 and support 4, shell 1 is made of low carbon steel plate with a thickness of 0.3-1.0mm; core plate 2 is metal plate, ceramic plate, glass plate, plastic plate or composite plate, etc., preferably 1-2mm thick aluminum alloy plate or 3-5mm thick tempered glass plate, etc.; the support 4 is made of metal, ceramics, glass or polymer, printed , printing, spraying, mechanical layout, etc. are distributed between the core boards 2 in a dot matrix. The supporting height of the support 4 is preferably 0.15-1.0mm, and the diameter of the supporting point is preferably 0.3-1.0mm. The method of making the metal vacuum composite panel with sealing strip edge sealing is as follows: First, cut two low-carbon steel plates with the same size and a thickness of 0.3 mm to make the shell 1, and use stamping to fold and shape the two low-carbon stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com