Patents

Literature

71results about How to "Eliminate edge stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

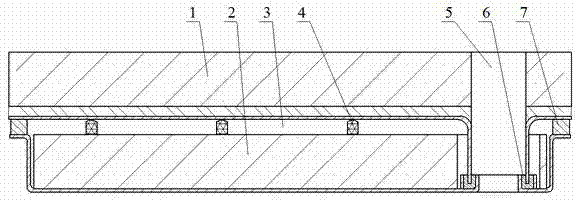

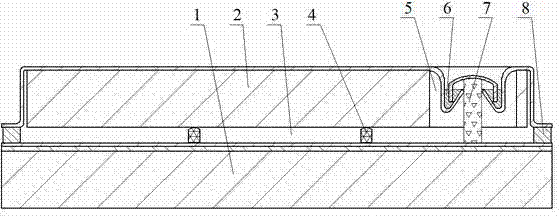

Double-vacuum-layer metal vacuum composite plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746690AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationComposite plate

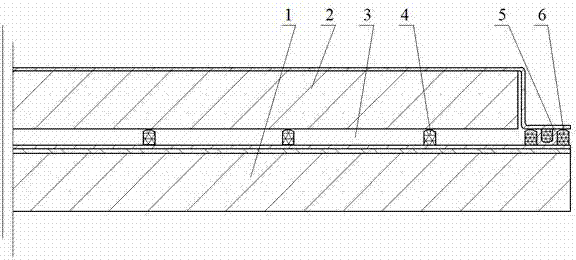

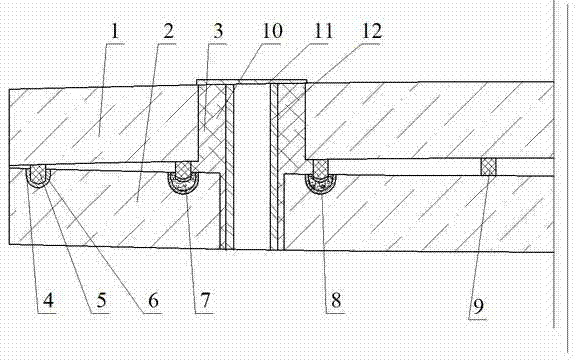

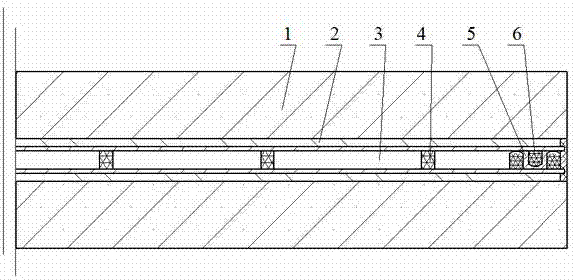

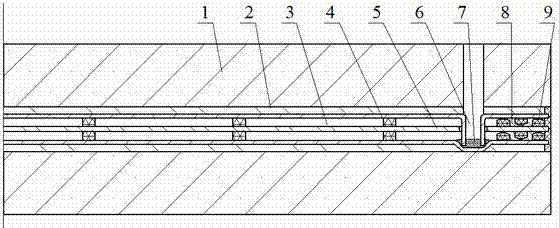

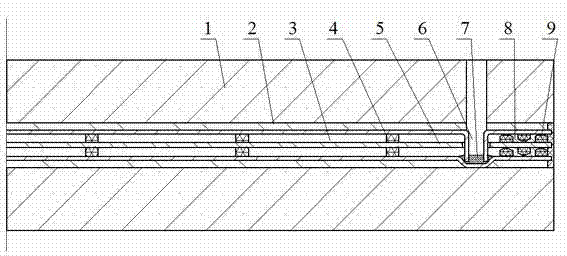

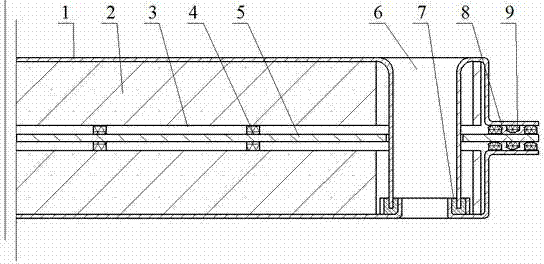

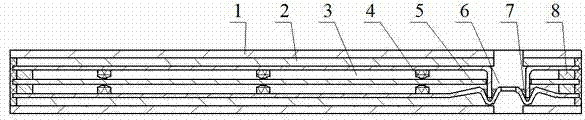

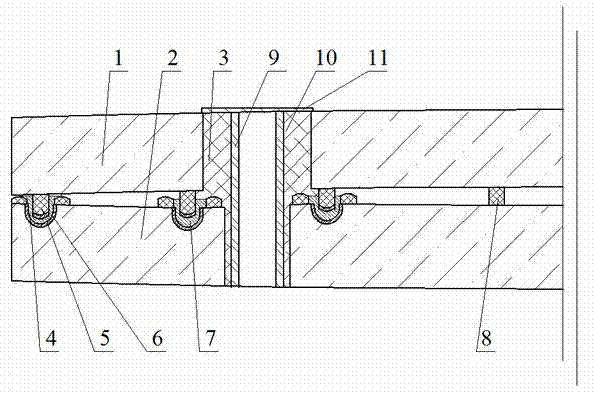

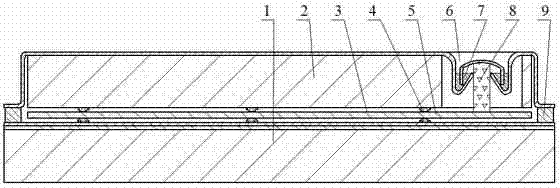

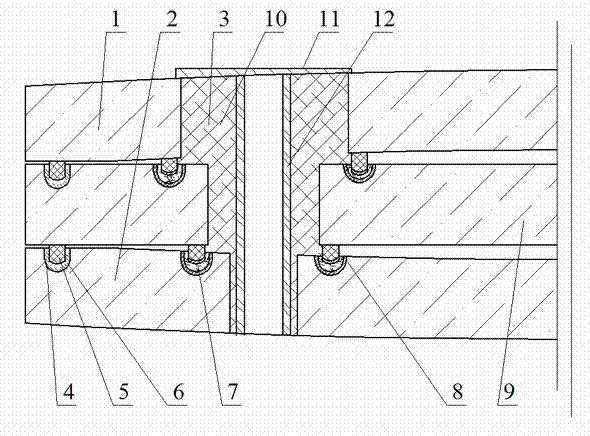

A double-vacuum-layer metal vacuum composite plate with the edge sealed by a seal strip comprises a housing, at least two core plates and a vacuum cavity and is characterized in that the housing is a low-carbon steel plate or a low-carbon steel composite plate, the core plates are located in the vacuum cavity formed through seal welding of the housing, the core plates provide additional strength for the housing and ensure the smoothness of the housing under atmospheric pressure, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers and are independently manufactured or are directly formed on the core plate or the partition plate. A manufacturing method of the double-vacuum-layer metal vacuum composite plate is simple in process, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

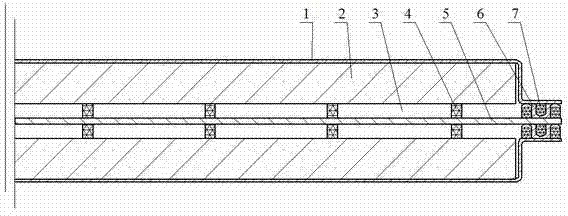

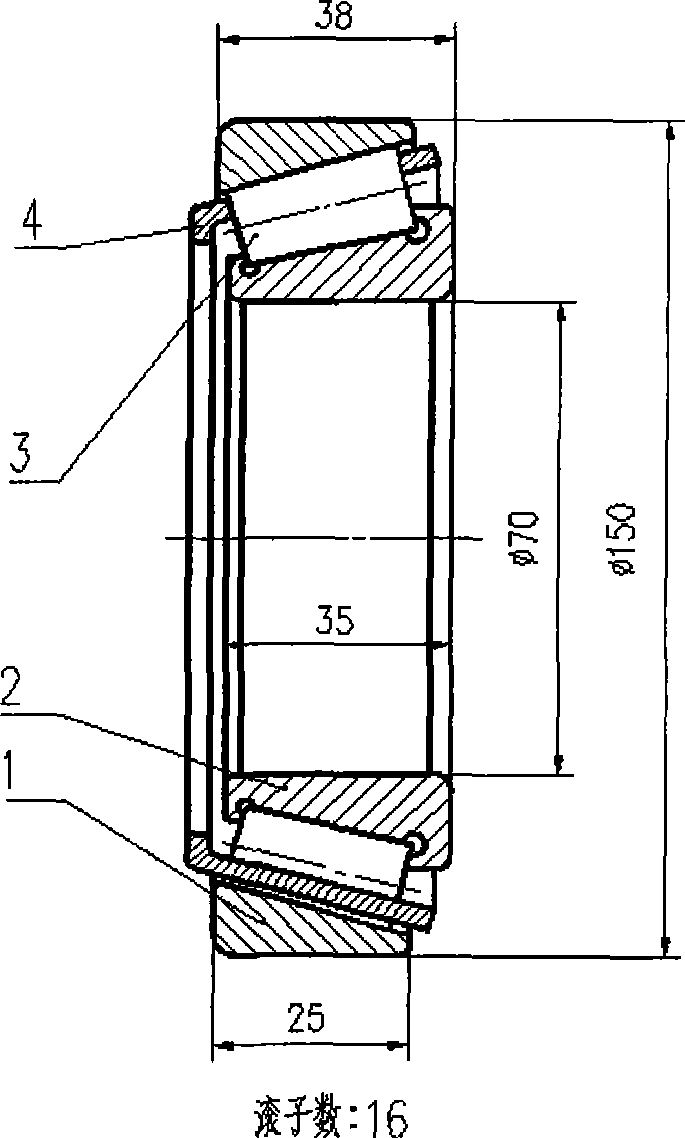

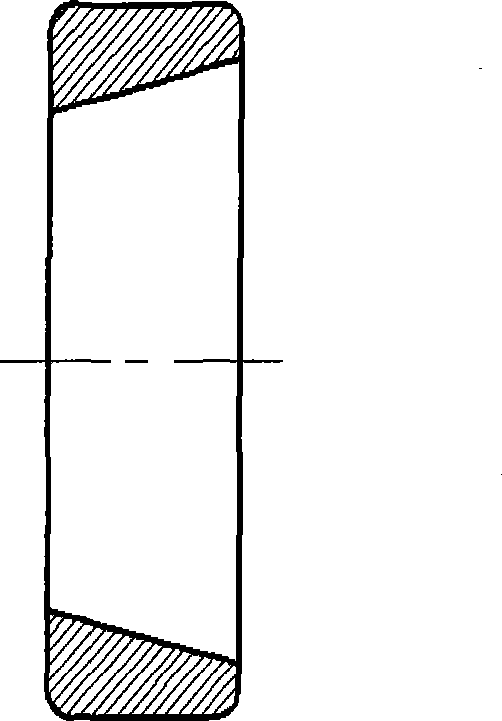

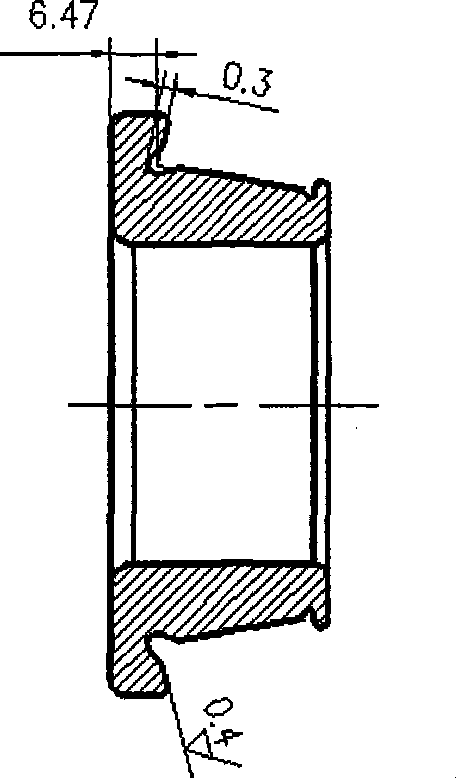

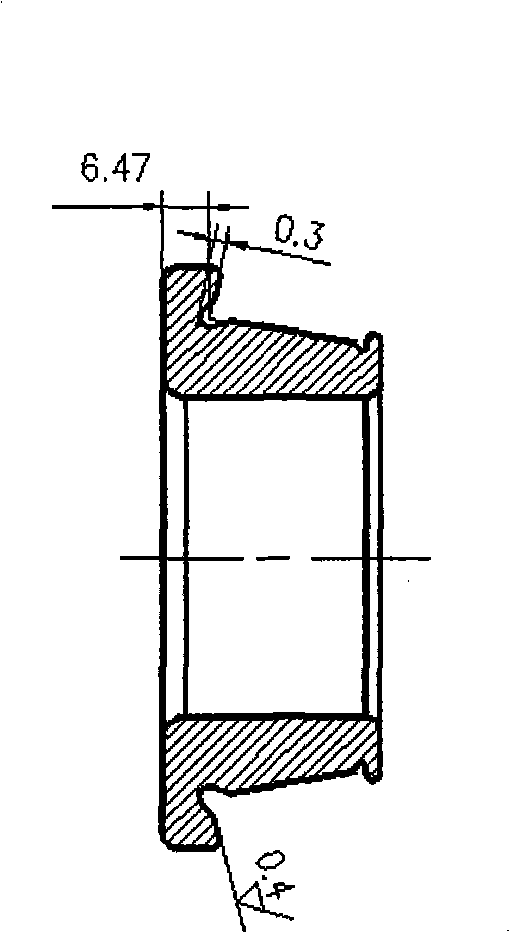

Tapered roller bearing with high strength and low friction torque

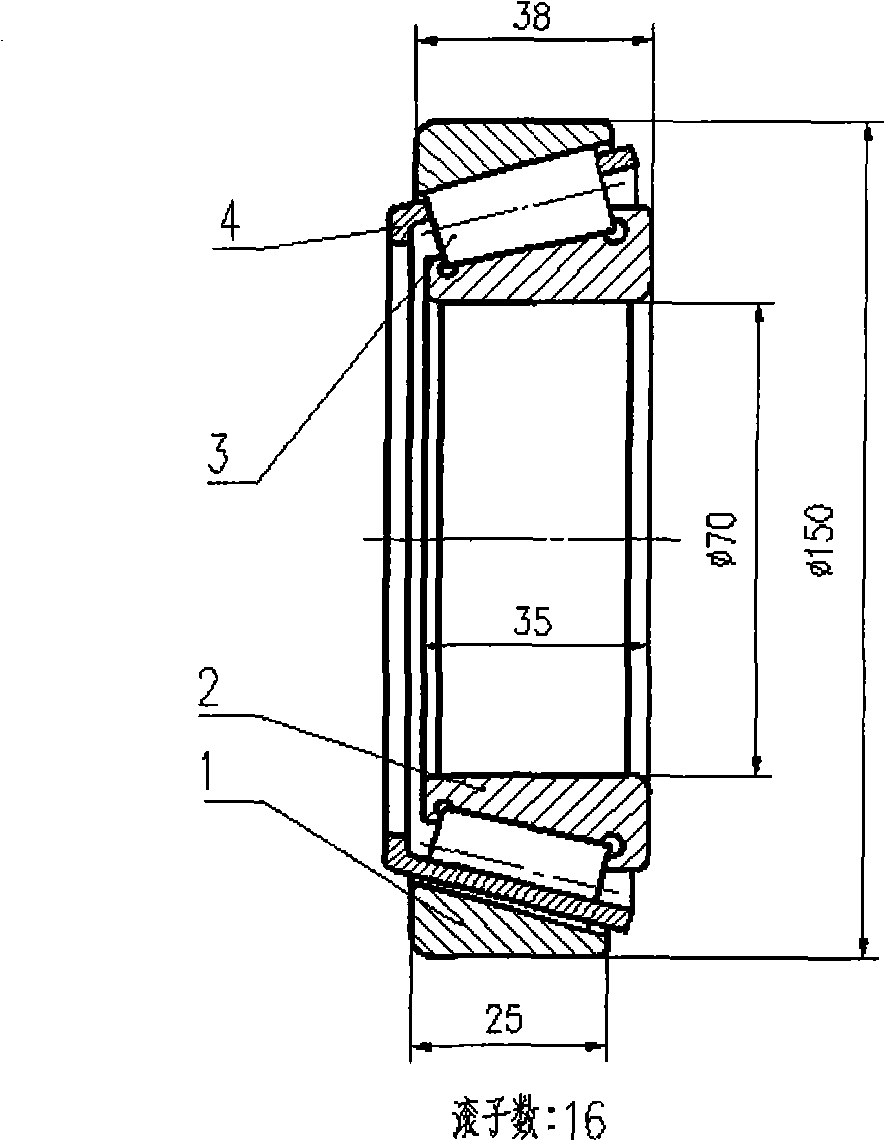

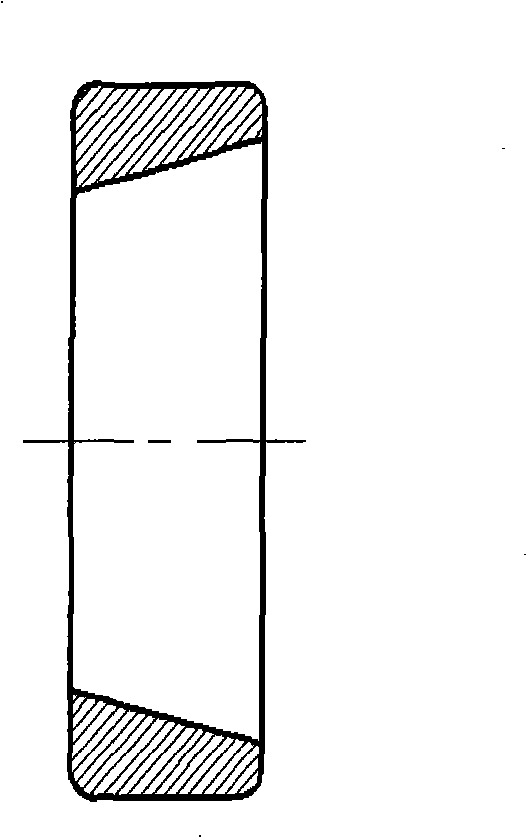

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reduces the energy consumption.

Owner:FUJIAN YONGAN BEARING

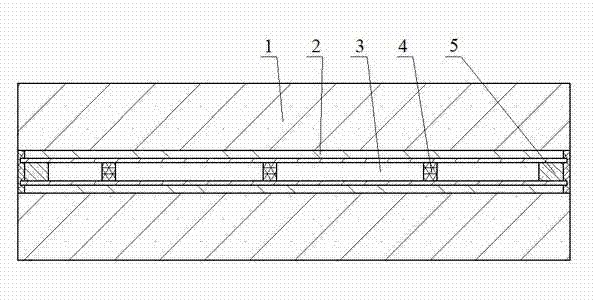

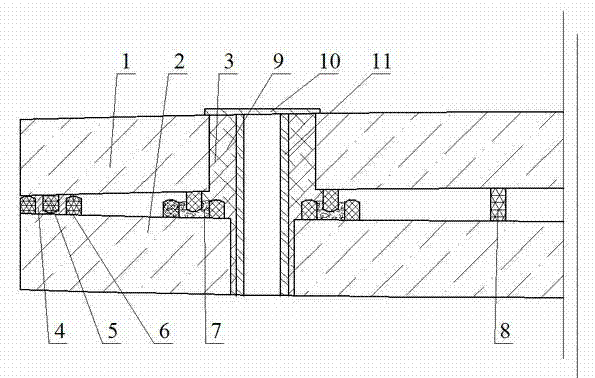

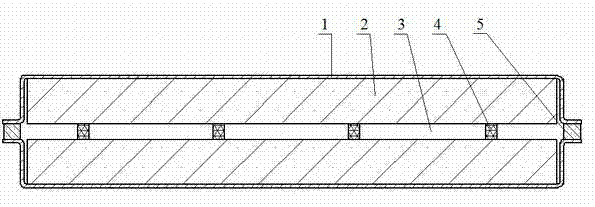

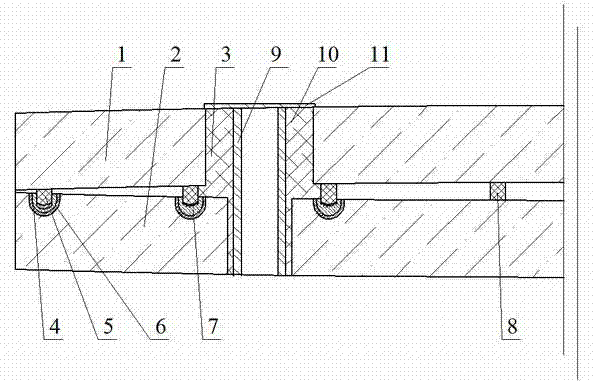

Composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746650AImprove air tightnessImprove sound insulationClimate change adaptationInsulation improvementThermal dilatationAir tightness

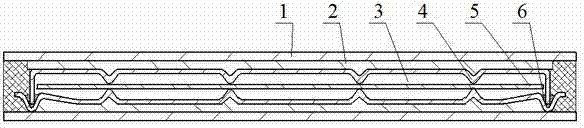

A composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a core plate and a vacuum cavity and is characterized in that the face plate is fixed to the upper surface outside the vacuum cavity in a welding or bonding mode, the core plate is arranged at the bottom of the inside of the vacuum cavity, the vacuum cavity is formed by welding a low-carbon steel plate, the face plate and / or the core plate provide / provides additional strength for the vacuum cavity, the vacuum cavity is welded and sealed by utilizing a glass solder in a vacuum furnace under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the coefficient of thermal expansion of the low-carbon steel plate is matched with that of the glass solder, and a support is arranged in the vacuum cavity and is independently manufactured or is directly formed on the inner wall of the vacuum cavity or the core plate. A manufacturing method of the composite vacuum plate is simple in process, the air impermeability of the vacuum cavity of the composite vacuum plate can be effectively ensured, the service life of the composite vacuum plate can be prolonged, and strength, heat-insulation, sound-insulation and fireproof performance and a decorative function can be improved.

Owner:戴长虹

Glass welded double-vacuum-layer metal composite vacuum plate and production method thereof

InactiveCN104746664AImprove sound insulationSolve the edge cold bridge problemClimate change adaptationInsulation improvementThermal dilatationFire resistance

The invention discloses a glass welded double-vacuum-layer metal composite vacuum plate. The double-vacuum-layer metal composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the panel is made from a metal plate, the panel and the vacuum cavity are integrally formed by the connecting layer, the vacuum cavity is formed by welding thin low carbon steel plates, and the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity; the vacuum cavity is hermetically sealed by a glass solder in a vacuum furnace at high vacuum and high temperature, the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched, a clapboard is arranged in the vacuum cavity and is used for dividing the vacuum cavity into double vacuum layers, and supports are arranged in the vacuum layers and are separately made or directly formed on the vacuum cavity or the clapboard. A production method of the double-vacuum-layer composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Metal-welded sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips and manufacturing method thereof

Metal-welded sealed convex vacuum glass with edges sealed by sealing grooves and sealing strips is disclosed. The convex vacuum glass comprises upper glass and lower glass which are convex glass. The upper glass is provided with one to four air extracting holes. The peripheries of the upper glass and each air extracting hole are provided with sealing strips. Corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves and sealing strips. After being heated, the upper glass and the lower glass are subjected to sheet combination at a high temperature, and the peripheries of the upper glass and the lower glass are welded under elevated pressure by alloy solder in an atmosphere heating furnace. Each air extracting hole is sealed by utilization of metal solder in a vacuum furnace. A sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743825AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; peripheries of the upper glass and each air extracting hole are provided with sealing strips; corresponding positions of the periphery of the lower glass and each air extracting hole are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. Tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass composite vacuum panel with sealing strips and mounting holes and manufacturing method thereof

InactiveCN104746719AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingAlloyComposite plate

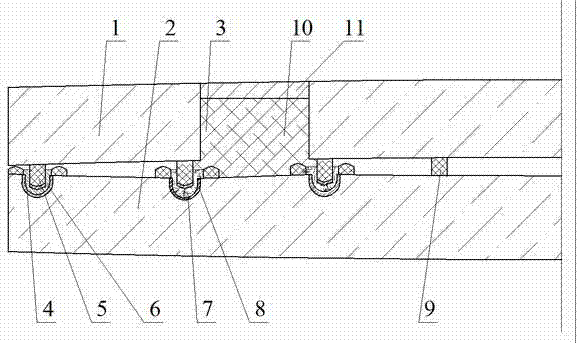

A glass composite vacuum panel with sealing strips and mounting holes comprises a surface plate, a connecting layer and a vacuum chamber and is characterized in that the mounting holes are combined with pumping holes and penetrate through the whole composite plate, the surface plate is a glass plate, the vacuum chamber is a closed chamber formed by a metal plate subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of a low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of the pumping holes preformed in the vacuum chamber with low-temperature solder in a vacuum furnace according to the principle of liquid seal, the low-temperature solder comprises low-temperature metal and alloy solder, and supporting members are arranged in the vacuum chamber. A manufacturing method of the glass composite vacuum panel with the sealing strips and the mounting holes is simple in process. The manufactured glass composite vacuum panel with the mounting holes can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength and thermal insulation, sound insulation and fireproof performance can be improved.

Owner:戴长虹

Glass welded double-vacuum-layer metal vacuum composite plate and production method thereof

InactiveCN104746718AImprove sound insulationImprove the decorative effectCovering/liningsHeat proofingThermal dilatationComposite plate

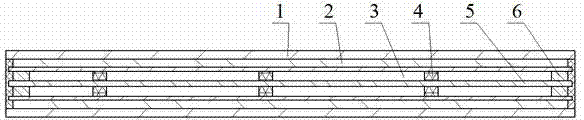

The invention discloses a glass welded double-vacuum-layer metal vacuum composite plate. The double-vacuum-layer metal vacuum composite plate comprises a shell, core veneers and a vacuum cavity, and is characterized in that the shell is made from low carbon steel plates or low carbon steel composite plates, the core veneers are located in the vacuum cavity formed by hermetically welding the shell, the number of the core veneers is at least two and the core veneers are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure and the vacuum cavity is hermetically sealed by a glass solder at high vacuum and high temperature in a vacuum furnace; the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched, a clapboard is arranged in the vacuum cavity and is used for dividing the vacuum cavity into double vacuum layers, and supports are arranged in the vacuum layers and are separately made or directly formed on the vacuum cavity or the clapboard. A production method of the double-vacuum-layer composite vacuum plate provided by the invention is simple in process, and the strength, heat insulation, sound insulation, fire resistance and decorative function can be improved.

Owner:戴长虹

Glass composite vacuum plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746737AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationGlass composites

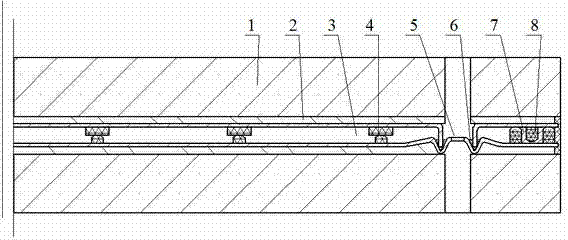

A glass composite vacuum plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a glass plate, the connecting layer enables the face plate and the vacuum cavity to be connected to form a whole, the vacuum cavity is formed by welding a low-carbon steel plate in a vacuum furnace by utilizing a glass solder under the high vacuum and high temperature, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder, and a support is arranged in the vacuum cavity and is independently manufactured or is directly formed on the vacuum cavity. A manufacturing method of the glass composite vacuum plate is simple in process, the manufactured glass composite vacuum plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, the air impermeability of the vacuum cavity of the glass composite vacuum plate can be effectively ensured, the service life of the glass composite vacuum plate can be prolonged, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

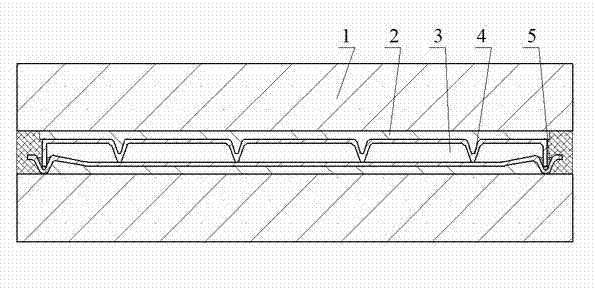

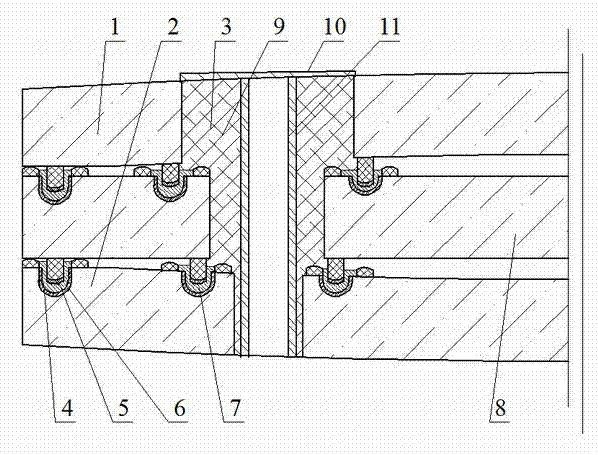

Double-vacuum-layer glass composite vacuum heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746736AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingGlass compositesAlloy

A double-vacuum-layer glass composite vacuum heat-insulation plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a glass plate, the vacuum cavity is a closed cavity formed by welding a low-carbon steel plate and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, the sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the vacuum cavity and a low-temperature solder in a vacuum furnace according to a liquid seal principle, the low-temperature solder includes low-temperature metal and an alloy solder, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer glass composite vacuum heat-insulation plate is simple in process, the manufactured double-vacuum-layer glass composite vacuum heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

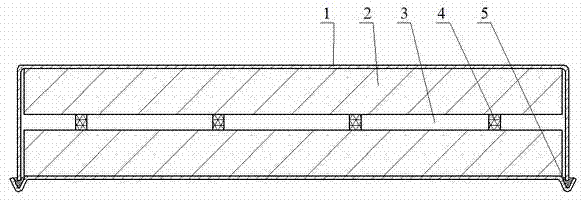

Glass welded metal vacuum insulated panel and production method thereof

InactiveCN104746671AImprove sound insulationImprove fire performanceClimate change adaptationInsulation improvementThermal dilatationComposite plate

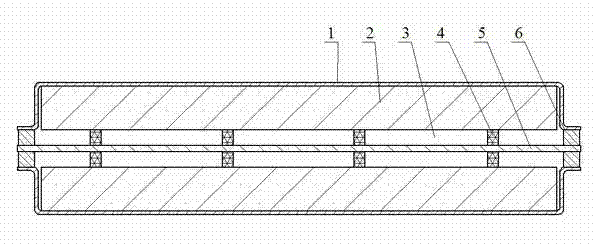

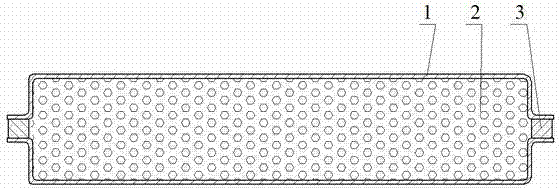

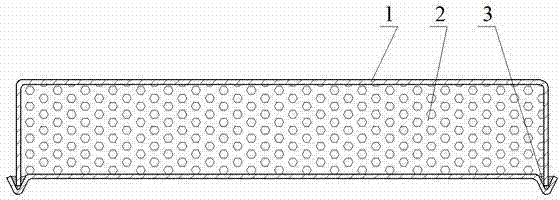

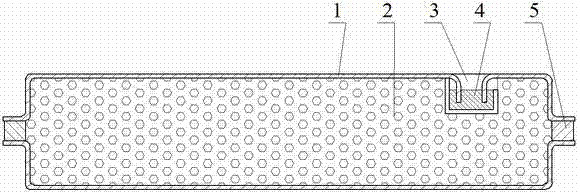

The invention provides a glass welded metal vacuum insulated panel. The glass welded metal vacuum insulated panel comprises a shell, a core material and a vacuum cavity, and is characterized in that the shell is made from either low carbon steel plates or low carbon steel composite plates, the core material is located in the vacuum cavity formed by hermetically welding the shell and is used for providing the additional strength to the shell to ensure the smoothness of the shell at barometric pressure; the vacuum cavity is a sealed cavity formed by welding and sealing a glass solder at high vacuum and high temperature and the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched. A production method of the glass welded metal vacuum insulated panel provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, the air-tightness of the vacuum cavity of the metal vacuum composite plate can be effectively ensured, the service life of the metal vacuum composite plate can be prolonged, and the strength, heat insulation, sound insulation, fire resistance and decorative function can be enhanced.

Owner:戴长虹

Glass welded glass composite vacuum plate welded with mounting hole and production method thereof

InactiveCN104746742AImprove sound insulationSolve the edge cold bridge problemCovering/liningsHeat proofingFire resistanceClosed cavity

The invention discloses a glass welded glass composite vacuum plate welded with a mounting hole. The glass welded glass composite vacuum plate comprises a panel, core veneers and a vacuum cavity, and is characterized in that the mounting hole and an extraction opening are combined, the mounting hole penetrates through the entire core veneers, the panel is fixed on the upper surface of the vacuum cavity by either a welding way or a gluing way and the core veneers are placed at the inner bottom of the vacuum cavity; the panel and / or the core veneers are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, the vacuum cavity is a closed cavity formed by carrying out glass welding at constant temperature and high temperature and sealing at constant pressure to a low carbon steel plate, the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a support is arranged in the vacuum cavity. A production method of the glass composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation, fire resistance and decorative function can be improved.

Owner:戴长虹

Glass welded ceramic composite vacuum plate and production method thereof

InactiveCN104746748AImprove sound insulationSolve the edge cold bridge problemCovering/liningsHeat proofingThermal dilatationCeramic composite

The invention discloses a glass welded ceramic composite vacuum plate. The ceramic composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the panel is made from a ceramic plate or a ceramic tile, the panel and the vacuum cavity are integrally formed by the connecting layer, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity so as to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding and sealing at constant pressure and high temperature and sealing at high temperature in vacuum to low carbon steel plates; the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched, and a support is arranged in the vacuum cavity and is separately made or directly formed in the vacuum cavity. A production method of the ceramic composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, the air-tightness of the stone composite vacuum plate can be effectively ensured, the service life of the ceramic composite vacuum plate can be prolonged, and the strength, heat insulation, sound insulation and fire resistance can be enhanced.

Owner:戴长虹

Glass welded composite vacuum plate with getter and production method thereof

InactiveCN104746723AIncrease vacuumExtension of timeCovering/liningsHeat proofingAir tightnessCarbon steel

The invention discloses a glass welded composite vacuum plate with a getter. The composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the panel is made from either a metal plate or a metal composite plate, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high pressure to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a support and a getter are arranged in the vacuum cavity. A production method of the composite vacuum plate with the getter provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Double-vacuum-layer ceramic composite vacuum heat-insulation plate with edge sealed by seal strip and manufacturing method thereof

InactiveCN104746697AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingThermal dilatationCeramic composite

A double-vacuum-layer ceramic composite vacuum heat-insulation plate with the edge sealed by a seal strip comprises a face plate, a connecting layer and a vacuum cavity and is characterized in that the face plate is a ceramic plate or is made of ceramic tiles, the vacuum cavity is a closed cavity formed by welding a low-carbon steel plate and sealing the edge by utilizing a glass solder under the constant pressure and high temperature and performing high-temperature sealing under the vacuum condition, the seal strip is arranged at the welding position of the edge portion of the low-carbon steel plate, and the low-carbon steel plate is matched with the coefficient of thermal expansion of the glass solder. The sealing is automatic sealing performed by utilizing an air exhaust opening pre-formed in the vacuum cavity and a low-temperature solder in a vacuum furnace according to a liquid seal principle, a partition plate is arranged in the vacuum cavity and divides the vacuum cavity into two to form double vacuum layers, and supports are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer ceramic composite vacuum heat-insulation plate is simple in process, the manufactured double-vacuum-layer ceramic composite vacuum heat-insulation plate can overcome the shortcomings of existing heat preservation plates and vacuum heat-insulation plates, and strength and heat-insulation, sound-insulation and fireproof performance can be improved.

Owner:戴长虹

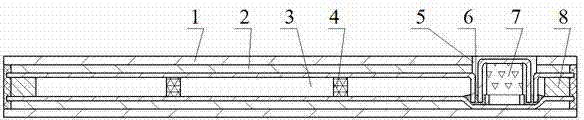

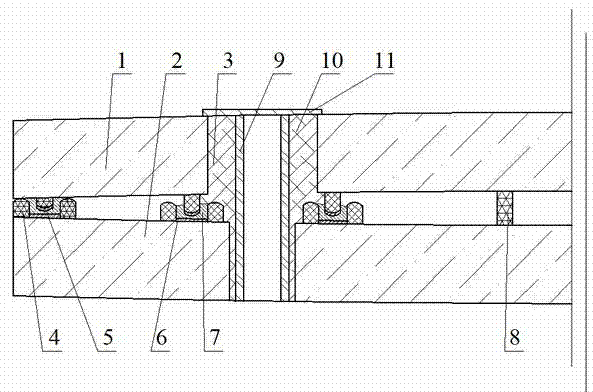

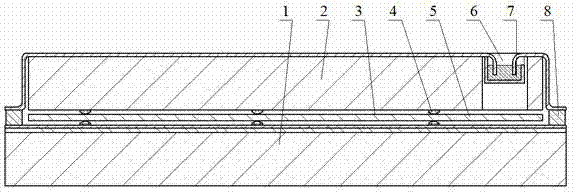

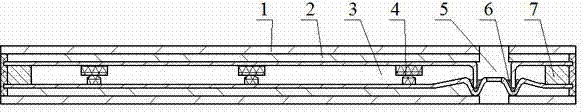

Double-vacuum-layer metal vacuum composite panel with sealing strips and mounting holes and manufacturing method thereof

InactiveCN104746686AImprove air tightnessImprove sound insulationCovering/liningsHeat proofingClosed chamberComposite plate

A double-vacuum-layer metal vacuum composite panel with sealing strips and mounting holes comprises a housing, a core plate and a vacuum chamber and is characterized in that the mounting holes are combined with pumping holes, the housing is a low-carbon steel plate, the core plate is arranged in the vacuum chamber to provide the housing with additional strength to ensure the smoothness of the housing at atmospheric pressure, the vacuum chamber is a closed chamber formed by the housing subjected to glass soldering edge sealing at atmospheric pressure and high temperature and high-temperature opening sealing in vacuum, welding portions of the edge of the low-carbon steel plate are provided with the sealing strips, the opening sealing is the automatic sealing of the pumping holes preformed in the housing with low-temperature solder in a vacuum furnace according to the principle of liquid seal, a separation plate separating the vacuum chamber into two to form double vacuum layers is arranged in the vacuum chamber, and supporting members are arranged in the vacuum layers. A manufacturing method of the double-vacuum-layer metal vacuum composite panel with the sealing strips and the mounting holes is simple in process. The manufactured double-vacuum-layer metal vacuum composite panel can overcome the deficiencies of existing insulation boards and vacuum insulation panels and the strength, thermal insulation, sound insulation and fireproof performance and decorative functions can be improved.

Owner:戴长虹

Glass welded double-vacuum-layer metal composite vacuum plate with mounting hole and production method thereof

InactiveCN104746721AImprove sound insulationSolve the edge cold bridge problemCovering/liningsHeat proofingComposite slabFire resistance

The invention discloses a glass welded double-vacuum-layer metal composite vacuum plate with a mounting hole. The double-vacuum-layer metal composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the mounting hole and an extraction opening are combined, the panel is made from either a metal plate or a metal composite plate, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high pressure to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a clapboard is arranged in the vacuum cavity and is used for dividing the vacuum cavity into double vacuum layers in which supports are arranged. A production method of the double-vacuum-layer metal composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Glass welded metal vacuum insulation board with extraction opening and production method thereof

InactiveCN104746720AImprove sound insulationSolve Welding ProblemsCovering/liningsHeat proofingThermal dilatationAlloy

The invention discloses a glass welded metal vacuum composite insulation board with an extraction opening. The metal vacuum composite insulation board comprises a shell, a core material and a vacuum cavity, and is characterized in that the shell is made from either a low carbon steel plate or a low carbon steel composite plate, the core material is located in the vacuum cavity and is used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high pressure to the shell and the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and the low temperature solder comprises a low temperature metal and an alloy solder. A production method of the metal vacuum composite insulation board provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Metal-welded convex vacuum glass having installing holes by metal welding at sealed edge of sealing strips

The invention relates to a convex vacuum glass having installing holes by metal welding at sealed edge of a sealing strip, which comprises an upper glass and a lower glass, the installing holes are provided, 1-4 installing holes are provided, at least a sealing strip is respectively provided at circumference of the upper glass and the installing hole, at least two sealing strips are provided at circumference of the lower glass, at least a sealing strip is arranged at the lower glass corresponding to the installing hole, the sealing strip of the upper glass is inserted between sealing strips of the lower glass, the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a metal solder in a vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and usage life is increased.

Owner:戴长虹

Glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips

InactiveCN104743852AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

The invention relates to a glass-welded convex vacuum glass having installing holes with edge sealed by sealing strips, which comprises an upper glass and a lower glass, the installing holes and extraction openings are combined as an integral body, 1-4 installing holes are arranged, at least a sealing strip is provided at circumference of the upper glass and the extraction opening, at least two sealing strips are provided at circumference of the lower glass and the extraction opening, the sealing strip of the upper glass is inserted between the sealing strips of the lower glass; the upper glass and the lower glass are rapidly heated and laminated at high temperature, the circumference can be welded together by pressurizing through a glass solder in a heating furnace, and the extraction opening is performed with on-line enclosing by using molten glass in a continuous vacuum furnace. The vacuum glass and its production method have the advantages that the process is simple and the production efficiency is high, the prepared vacuum glass can eliminate the stress of the sealed edge and can keep the toughening characteristic of the toughened glass, so that toughened vacuum glass can be massively produced, and its usage life is increased.

Owner:戴长虹

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s)

Metal-welded convex double-vacuum-layer glass provided with edges sealed by sealing grooves and sealing strips and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: the convex double-vacuum-layer glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the lower surfaces of the upper glass and the middle glass and the periphery of each mounting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and the mounting hole(s) are provided with the sealing grooves and sealing strips; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and two sealed vacuum layers are formed among the three sheets of glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass welded composite vacuum plate with getter and production method thereof

The invention discloses a glass welded composite vacuum plate with a getter. The glass welded composite vacuum plate comprises a panel, core veneers and a vacuum cavity and is characterized in that the panel is fixed on the upper outer surface of the vacuum cavity by either a welding way or a gluing way, the core veneers are placed in the inner bottom part of the vacuum cavity, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high pressure to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a support and a getter are arranged in the vacuum cavity. A production method of the composite vacuum plate with the getter provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Glass welded metal vacuum composite plate and production method thereof

InactiveCN104746728AImprove sound insulationImprove the decorative effectCovering/liningsHeat proofingThermal dilatationComposite plate

The invention discloses a glass welded metal vacuum composite plate. The glass welded composite vacuum insulation board comprises a shell, core veneers and a vacuum cavity, and is characterized in that the shell is made from either low carbon steel plates or low carbon steel composite plates, the core veneers are located in the vacuum cavity formed by hermetically welding the shell and are used for providing additional strength to the shell to ensure the smoothness of the shell at barometric pressure; the vacuum cavity is hermetically sealed by using a glass solder at high vacuum and high temperature in a vacuum furnace, the coefficients of thermal expansion of the low carbon steel plate and the glass solder are matched, the number of the core veneers is at least two, and a support is arranged between every two core veneers and is separately made or directly formed on the core veneers. A production method of the glass welded metal vacuum composite plate provided by the invention is simple in process, the air-tightness of the vacuum cavity of the metal vacuum composite plate can be effectively ensured, the service life of the metal vacuum composite plate can be prolonged, and the strength, heat insulation, sound insulation, fire resistance and decorative function can be enhanced.

Owner:戴长虹

Glass welded double-vacuum-layer composite vacuum insulation board and production method thereof

InactiveCN104746678AImprove sound insulationImprove the decorative effectClimate change adaptationInsulation improvementPolymer scienceFire resistance

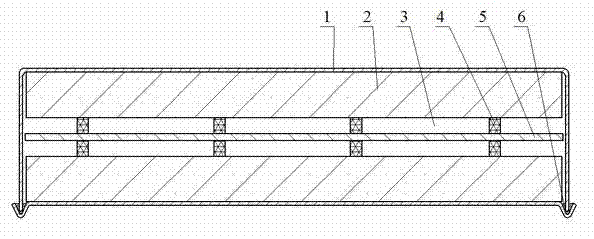

The invention discloses a glass welded double-vacuum-layer composite vacuum insulation board. The double-vacuum-layer composite vacuum insulation board comprises a panel, core veneers and a vacuum cavity, and is characterized in that the panel is fixed on the upper outer surface of the vacuum cavity, the core veneers are placed at the inner bottom of the vacuum cavity, and the panel and / or the core veneers are used for providing additional strength to the vacuum cavity so as to ensure the smoothness of the vacuum cavity at barometric pressure, the vacuum cavity is a closed cavity formed by carrying out glass welding at constant temperature and high temperature and sealing at constant pressure to low carbon steel plates and the sealing is that an extraction opening preformed in the vacuum cavity is sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory; a clapboard is arranged in the vacuum cavity and is used for dividing the vacuum cavity into double vacuum layers, and supports are arranged in the vacuum layers and are separately made or directly formed on the vacuum cavity or the clapboard. A production method of the double-vacuum-layer composite vacuum insulation board provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation, fire resistance and decorative function can be improved.

Owner:戴长虹

Glass welded double-vacuum-layer composite vacuum plate with getter and production method thereof

InactiveCN104746660ALow costIncrease vacuumClimate change adaptationInsulation improvementFire resistanceCarbon steel

The invention discloses a glass welded double-vacuum-layer composite vacuum plate with a getter. The double-vacuum-layer composite vacuum plate comprises a panel, core veneers and a vacuum cavity, and is characterized in that the panel is fixed on the upper outer surface of the vacuum cavity, the core veneers are placed in the inner bottom of the vacuum cavity, the panel and / or the core veneers are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, the vacuum cavity is a closed cavity formed by carrying out glass welding at normal pressure and high temperature and sealing at high temperature to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a clapboard is arranged in the vacuum cavity and is used for dividing the vacuum cavity into double vacuum layers in which supports are arranged. A production method of the double-vacuum-layer composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

InactiveCN104743795AShorten the timeSolve productivityGlass reforming apparatusGlass productionHigh volume manufacturingEngineering

High-temperature-sheet-combination convex double-vacuum-layer glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex double-vacuum-layer glass comprises upper glass, lower glass and middle glass, and is characterized in that: each mounting hole and a corresponding air extracting hole are of an integrated structure; the number of the mounting hole(s) is 1-4; the upper surfaces of the upper glass and the middle glass and the periphery of each air extracting hole are provided with sealing strips; corresponding positions of peripheries of the upper surfaces of the middle glass and the lower glass and each air extracting hole are provided with the sealing grooves; after the three sheets of glass are rapidly heated, peripheries of the three sheets of glass are welded under elevated pressure by glass solder in a heating furnace; each air extracting hole is automatically sealed by utilization of metal solder in a vacuum furnace; and two vacuum layers are formed among the upper glass, the lower glass and the middle glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Tapered roller bearing with high strength and low friction torque

The invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clampeThe invention relates to a tapered roller bearing with high strength and low friction torque, comprising an outer ring, an inner ring, a plurality of rollers and a cage, wherein the rollers are clamped between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curd between the outer ring and the inner ring and used for supporting and realizing relatively rotating; and the cage is used for guiding the rollers to move; a big rib of the inner ring is a convex curved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner rved rib; the root part width of the big rib of the inner ring is larger than 6.47 mm, and the axial depth of an oil groove is smaller than 0.5 mm; the raceway buses and the roller buses of the inner ring and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is smaing and the outer ring are in a logarithm curve convexity shape; the number of the rollers is less than 16, the length of the rollers is smaller than 24 mm, and the convex diameter of a raceway is small; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reducesll; the sphere base surface diameter of the rollers is smaller than 136 mm, and the diameter of the rollers is larger than 21.671 mm. The invention has long service life, saves the energy and reducesthe energy consumption.the energy consumption.

Owner:FUJIAN YONGAN BEARING

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s)

Metal-welded convex vacuum glass provided with edges sealed by sealing grooves and provided with mounting hole(s) is disclosed. The convex vacuum glass comprises upper glass and lower glass, and is characterized in that: the convex vacuum glass is provided with the mounting hole(s); the number of the mounting hole(s) is 1-4; the upper glass and the lower glass are convex glass; peripheries of the upper glass and the mounting hole(s) are provided with sealing strips; corresponding positions of the periphery of the lower glass and the mounting hole(s) are provided with the sealing grooves; after being rapidly heated, the upper glass and the lower glass are subjected to sheet combining at a high temperature, and peripheries of the upper glass and the lower glass and the periphery of each mounting hole are welded under elevated pressure by metal solder in a vacuum furnace; and a sealed vacuum layer is formed between the upper glass and the lower glass. The vacuum glass and a manufacturing method thereof are simple in process and high in production efficiency. The manufactured tempered vacuum glass eliminates edge sealing stress and maintains tempered characteristics of tempered glass. The tempered vacuum glass can be produced in a large scale, and the service lifetime of the tempered vacuum glass can be prolonged.

Owner:戴长虹

Glass welded metal composite vacuum plate welded with mounting hole and production method thereof

InactiveCN104746709AImprove sound insulationSolve the edge cold bridge problemCovering/liningsHeat proofingComposite plateFire resistance

The invention discloses a glass welded metal composite vacuum plate welded with a mounting hole. The glass welded metal composite vacuum plate comprises a panel, a connecting layer and a vacuum cavity, and is characterized in that the mounting hole and an extraction opening are combined, the mounting hole penetrates through the entire composite plate, the panel and / or the connecting layer are used for providing additional strength to the vacuum cavity to ensure the smoothness of the vacuum cavity at barometric pressure, and the vacuum cavity is a closed cavity formed by carrying out glass welding at constant temperature and high temperature and sealing at constant pressure to a low carbon steel plate; the sealing is that an extraction opening preformed in the vacuum cavity is automatically sealed by a low temperature solder in a vacuum furnace according to a liquid sealing theory, and a support is arranged in the vacuum cavity. A production method of the glass welded metal composite vacuum plate provided by the invention is simple in process, the defects of an existing insulation board and an existing vacuum insulated panel can be overcome, and the strength, heat insulation, sound insulation and fire resistance can be improved.

Owner:戴长虹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com