Glass welded metal vacuum insulated panel and production method thereof

A technology of vacuum insulation board and glass solder, which is applied in the direction of insulation improvement, climate change adaptation, building components, etc., can solve problems such as cold bridges and thermal insulation performance not reaching the best state, achieve thin thickness, and solve edge cold bridges problems, effects of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

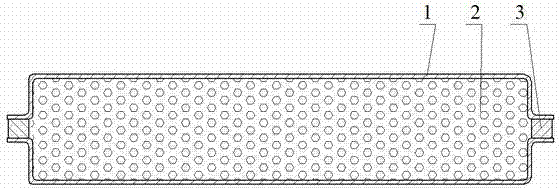

[0029] Embodiment 1: see figure 1 , the glass-welded metal vacuum insulation panel consists of an outer shell 1 and a core material 2, the outer shell 1 is composed of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core material 2 is glass fiber, pearl sand, perlite, vermiculite, airgel etc., the core material 1 is preferably dried, packed in a plastic bag, pre-vacuumized, and the like. The manufacturing method of the glass-welded metal vacuum insulation panel is as follows: first, two low-carbon steel plates with the same size and a thickness of 0.3 mm are cut to make the shell 1, and the two low-carbon steel plates are folded and formed by stamping; secondly, After drying pearl sand or perlite with a certain particle size in a continuous kiln, put it into a plastic bag and seal it after vacuuming to make it a core material with a small volume and a certain shape; Material 2 is put into the cavity of lower shell 1, and glass solder 3 is coated on the welding par...

Embodiment 2

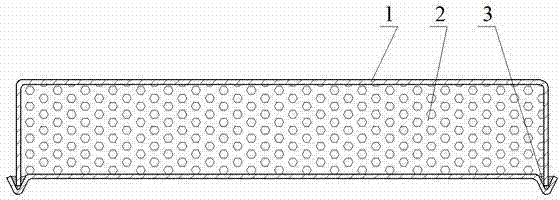

[0030] Example 2: See Example 1 and figure 2 , is basically the same as Example 1, except that the low-carbon steel plate forming the shell 1 is directly stamped out a groove for edge sealing during stamping, and glass solder is placed in the groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com