Glass welded metal vacuum composite plate and production method thereof

A composite board, glass solder technology, applied in building components, thermal insulation, sound insulation, etc., to avoid damage, save materials, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

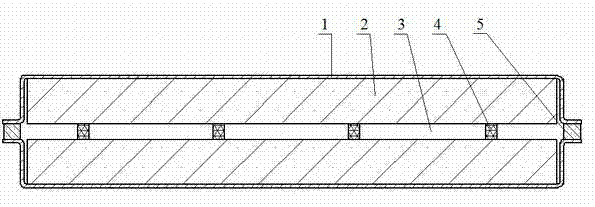

[0032] Embodiment 1: see figure 1, the glass-welded metal vacuum composite board is composed of a shell 1, a core plate 2, a vacuum chamber 3 and a support 4, the shell 1 is composed of a low-carbon steel plate with a thickness of 0.3-1.0mm; the core plate 2 is a metal plate, a ceramic plate, Glass plate, plastic plate or composite plate, etc., preferably 1-2mm thick aluminum alloy plate or 3-5mm thick tempered glass plate, etc.; support 4 is made of metal, ceramics, glass or high polymer, using printing, printing , spraying, mechanical placement, etc. are distributed between the core boards 2 in a lattice, the support height of the support 4 is preferably 0.15-1.0mm, and the diameter of the support point is preferably 0.3-1.0mm. The manufacturing method of the glass-welded metal vacuum composite panel is as follows: First, two low-carbon steel plates with the same size and a thickness of 0.3 mm are cut to make the shell 1, and the two low-carbon steel plates are folded and fo...

Embodiment 2

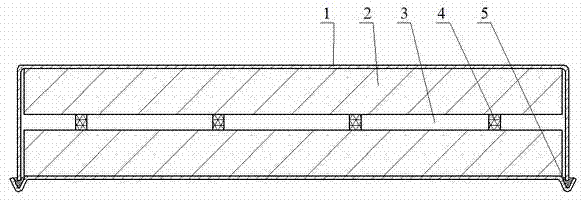

[0033] Example 2: See Example 1 and figure 2 , is basically the same as Example 1, except that the low-carbon steel plate forming the shell 1 is directly stamped out a sealing groove for edge sealing during stamping, and glass solder is placed in the sealing groove.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com