Glass welded ceramic composite vacuum plate and production method thereof

A technology of ceramic composite and vacuum panels, which is applied to building components, thermal insulation, sound insulation, etc., can solve the problems of not reaching the best thermal insulation performance, difficulty in combining thermal insulation materials, and poor thermal insulation performance, so as to achieve firm and reliable bonding and lower temperature , to ensure the effect of heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

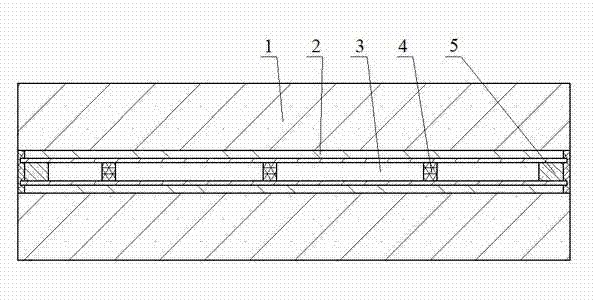

[0040] Embodiment 1: see figure 1 , the glass-welded ceramic composite vacuum panel is composed of a panel 1, a connecting layer 2, a vacuum chamber 3 and a support 4, and the panel 1 is composed of a ceramic plate or ceramic tile or soft tile or mosaic with a thickness of 2-12 mm; the connecting layer 2 is High-temperature-resistant adhesives can be selected from high-temperature-resistant phenolic resin adhesives, epoxy resin adhesives, silicone resin adhesives, polyimide and other organic adhesives that can be cured at room temperature or high temperature, as well as commonly used inorganic adhesives or organic-inorganic composite adhesives; 3. It is welded by low-carbon steel plate with a thickness of 0.3-1.0mm; the support 4 is made of metal, ceramics, glass or polymer, and is distributed in a vacuum in a dot matrix by printing, printing, spraying, mechanical layout, etc. In the cavity 3, the supporting height of the support 4 is preferably 0.15-1.0 mm, and the diameter o...

Embodiment 2

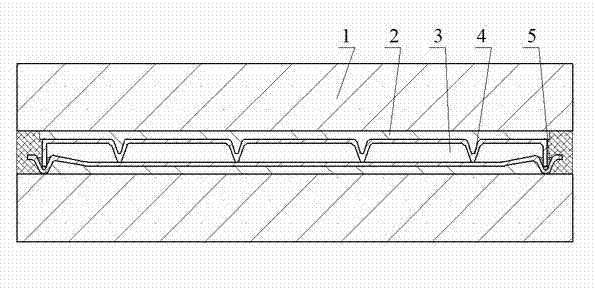

[0041] Example 2: See Example 1 and figure 2 , basically the same as Example 1, except that the low-carbon steel plate forming the vacuum chamber 3 is directly punched out of the support 4 and sealing grooves for edge sealing during stamping, and glass solder is placed in the sealing grooves.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com