House edge beam member

A technology for edge beams and components, applied in joists, girders, trusses, etc., can solve problems such as increased risk factor, frame structure deformation, and increased safety hazards for users, to prevent collapse and settlement, improve shear resistance, increase holistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be briefly described below in conjunction with the accompanying drawings.

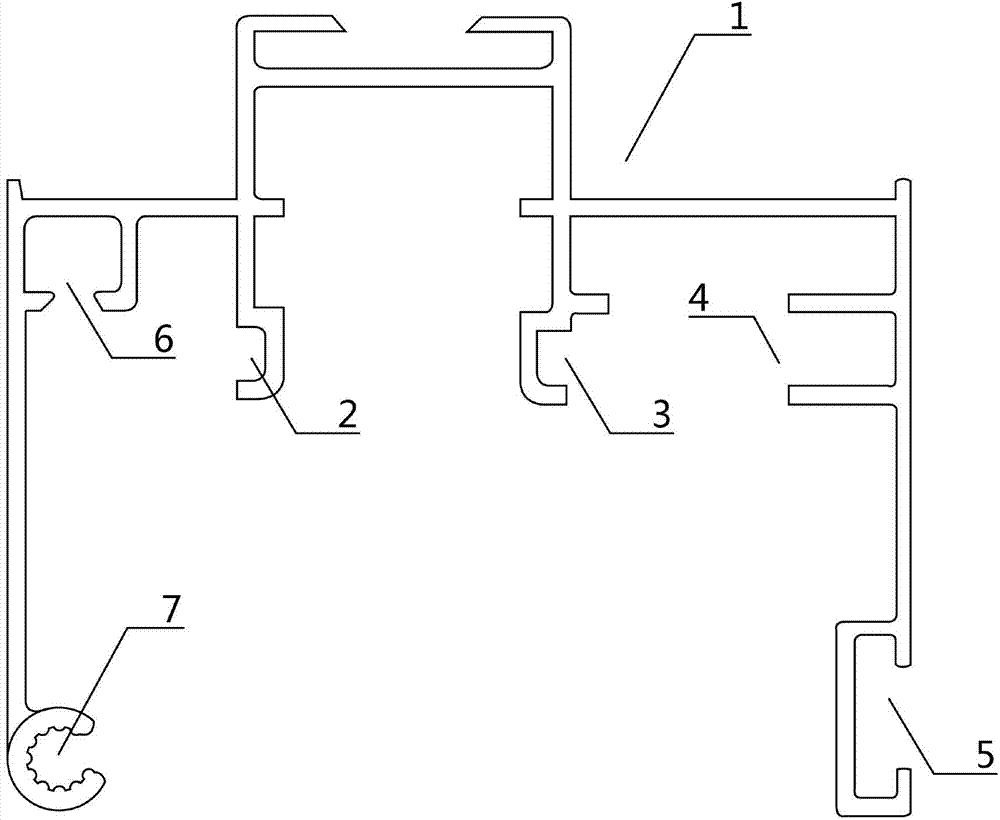

[0012] like figure 1 A side beam component of a house is shown, which is characterized in that it consists of a main frame 1, an inner hanging opening 2, an outer hanging opening 3, a double-layer insert plate 4, an outer fixing bayonet 5, an inner fixing bayonet 6 and a fixing ring 7, The inner hanging port 2 is located on the inner side of the main frame 1, the inner hanging port 2 is fixedly connected with the main frame 1, the outer hanging port 3 is located on the other side of the inner hanging port 2, and the outer hanging port 3 is connected to the main frame 1 is a fixed connection, the double-layer board 4 is located on the other side of the external hanging port 3, the double-layer board 4 is fixedly connected to the main frame 1, and the external fixing bayonet 5 is located on the double-layer board 4 In the lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com