Simulation experimenting device and method for high-temperature and high-pressure reinforced well wall drilling fluid

A simulation experiment device, high temperature and high pressure technology, applied in wellbore/well components, earthwork drilling, measurement, etc., can solve the problems of invariable fracture width, inability to simulate permeable formations, etc., achieve small experimental errors, complete functions, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

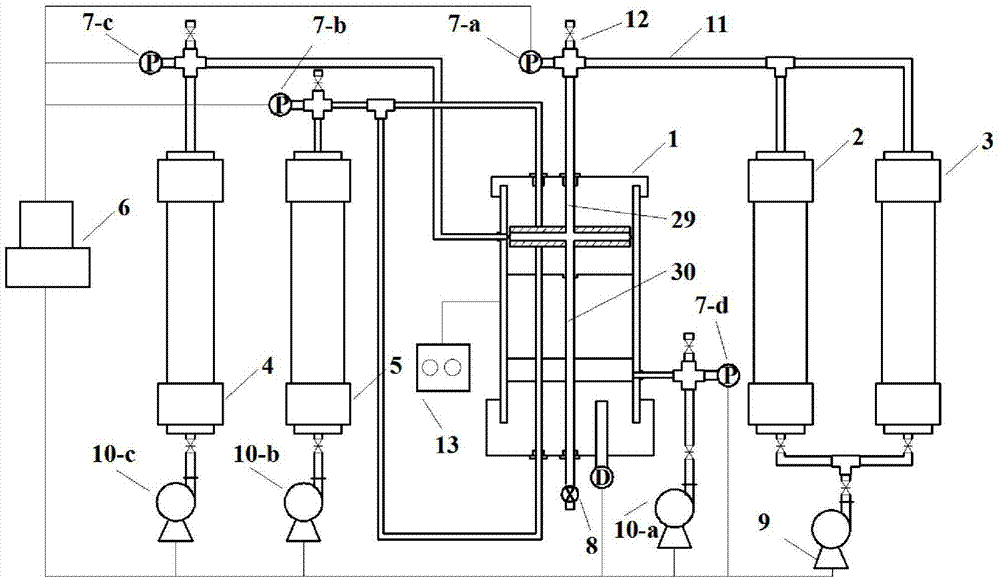

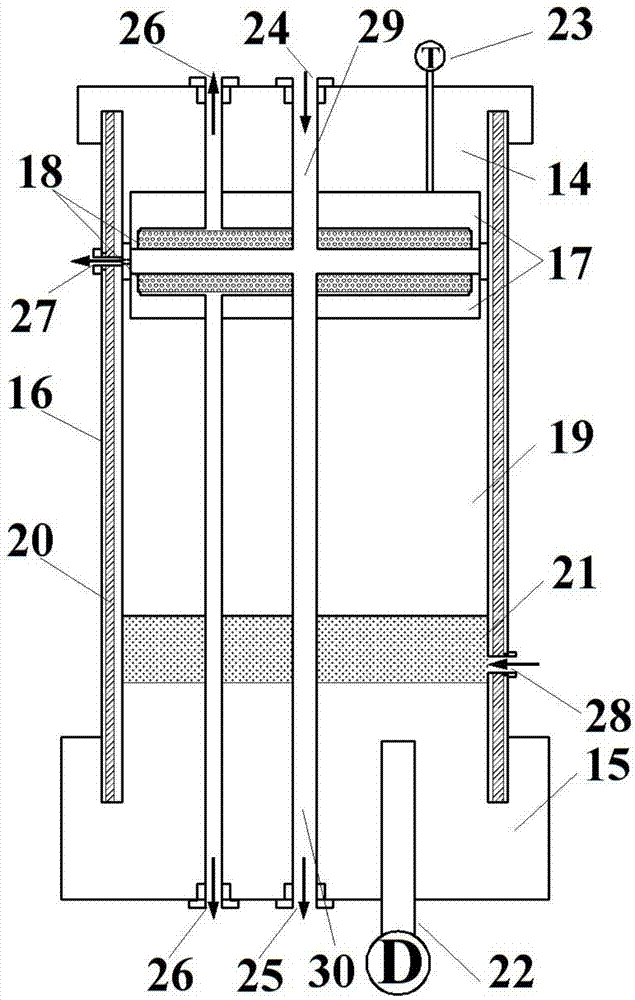

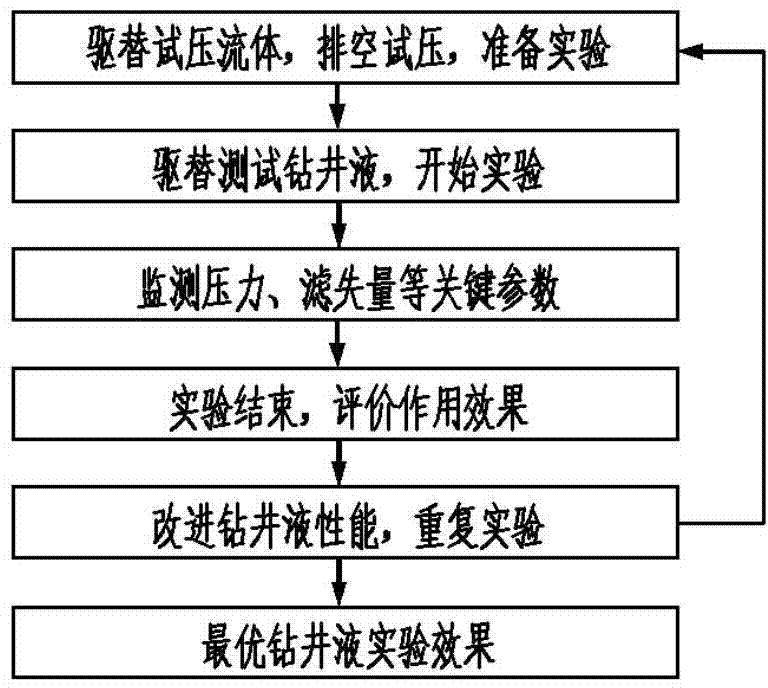

[0044] Such as Figure 1-2 shown.

[0045] A high-temperature and high-pressure borehole wall strengthening drilling fluid simulation experiment device, including a fracture leakage tank system, a drilling fluid delivery system and an industrial computer 6;

[0046] The fracture leakage kettle body system includes a fracture leakage kettle body 1, a pressurizing device, a rock core simulation device, a center pipe and a heating belt 20; the heating belt 20 and the rock core simulation device are arranged on the fracture leakage kettle body; the rock core simulation device is provided with The filtrate outlet 26 on the fracture surface and the filtrate outlet 27 at the tip of the fracture; the pressurizing device is connected to the core simulation device; the central pipe is installed through the core simulation device;

[0047] The heating zone 20 can fully simulate the temperature environment of complex formations; during the experiment, the test drilling fluid can be heate...

Embodiment 2

[0055] A high-temperature, high-pressure borehole wall strengthening drilling fluid simulation experiment device as described in Example 1, the difference is that: the upper center pipe 29 is connected to the delivery pipeline 11 through a high-pressure valve 12, and the heating belt 20 is connected with a temperature controller . By switching the high-pressure valve 12, functions such as circulating the air in the pipeline 11 and releasing pressure can be realized; the temperature controller ensures that the maximum experimental temperature of the heating belt 20 reaches 150°C, and controls the temperature control accuracy to ±1°C.

Embodiment 3

[0057] A high-temperature, high-pressure borehole wall strengthening drilling fluid simulation experiment device as described in Example 1, the difference is that: the plane where the inner side of the upper fluid loss medium sheet is located is on the same plane as the plane where the end of the upper central pipe 29 is located; The plane where the inside of the filter loss medium sheet is located is in the same plane as the plane where the end of the lower central pipe 30 is located; the upper filter loss medium sheet and the lower filter loss medium sheet are sealed with the central hole; the upper filter loss medium sheet and lower filter loss media pieces are ceramic or stainless steel. Ceramic or stainless steel materials are used to simulate fracture surfaces in formations with different permeability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com