Clutch device for mini tiller

A clutch device and clutch technology, applied in the field of tillage machines, can solve problems such as the increased gap between the connecting sleeve and the connecting boss, the clutch cover needs to be strengthened, and the connecting boss is easy to be cut, so as to improve the service life and long service life , the effect that is not easy to fail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

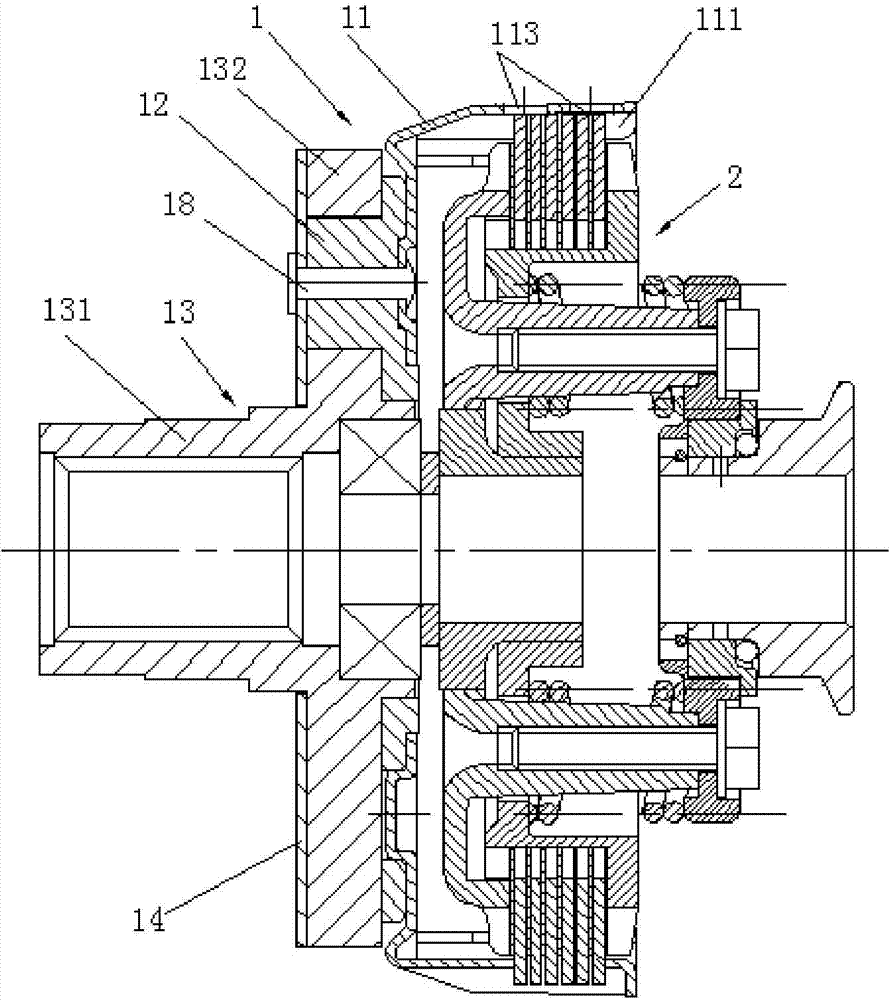

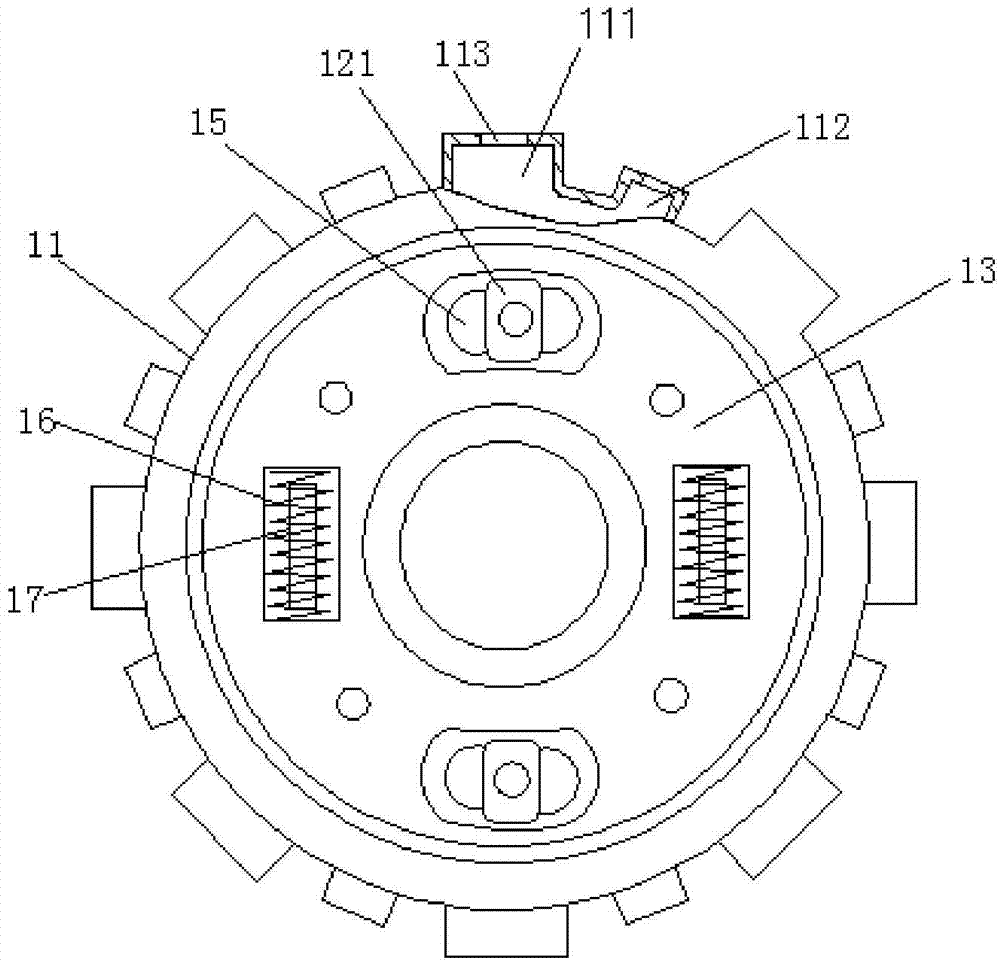

[0015] see figure 1 and figure 2 , a clutch device for a tiller, comprising a clutch cover assembly 1 and a center plate assembly 2 having a driving plate and a driven plate, the clutch cover assembly 1 includes a clutch cover 11 riveted together by rivets 18, a connecting convex plate 12 , Connection sleeve 13 and end plate 14. Clutch cover 11 is made by stamping steel plate. The cover ring of clutch cover 11 is an annular cover with continuous peripheral surface. On the inner side wall of the annular cover, there is an outwardly protruding engagement groove 111. The clutch cover 11 formed by stamping steel plate has a relatively high hardness. The common aluminum alloy cover is greatly improved, and the engaging groove 111 of the clamping active plate is not easy to be worn and stuck, which improves the service life of the clutch. On the annular co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com