A rotary valve and a five-tube adsorption tower using it, and an oxygen generator

A rotary valve and adsorption tower technology, which is applied in the field of household or medical oxygen production equipment, can solve the problems of high noise, no rotary valve, slow oxygen production efficiency, etc., and achieve high oxygen concentration and flow rate, good user experience and stable work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

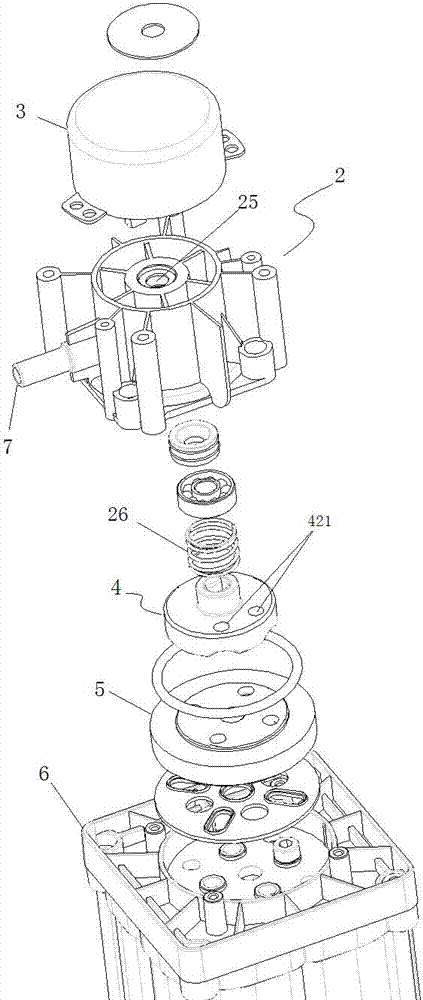

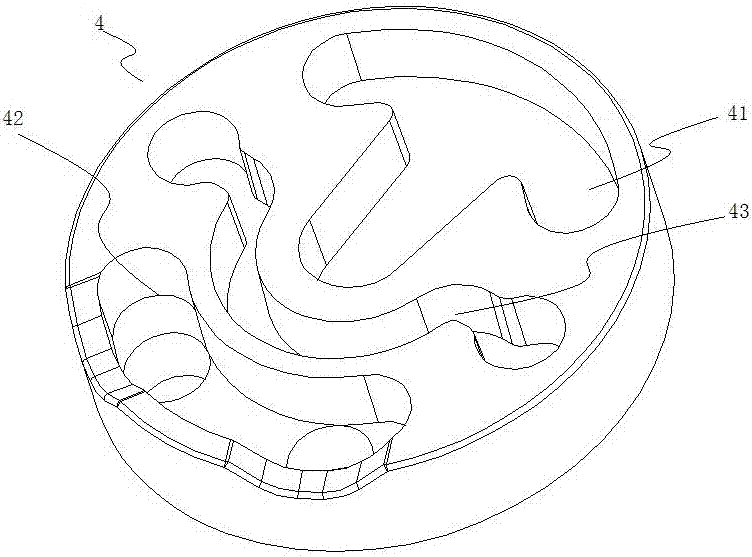

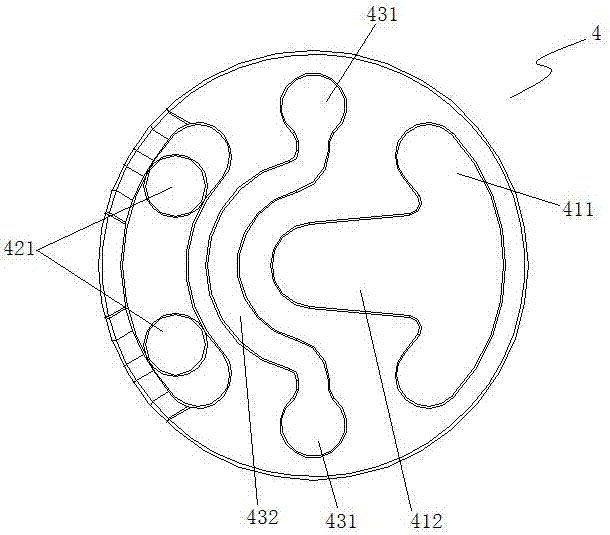

[0056] Such as Figure 1~4 As shown, a rotary valve includes a semi-closed separation chamber 2 with an open bottom, an air inlet nozzle 7 is arranged on one side of the separation chamber 2, a through hole N25 is opened on the top of the separation chamber 2, and the top of the separation chamber 2 A motor 3 is installed, the transmission rod of the motor is inserted into the through hole N25 and extends into the inner cavity of the separation chamber 2, the free end of the transmission rod of the motor is connected with a moving valve plate 4, and the lower end of the moving valve plate 4 is fitted with a static valve Plate 5, the movable valve plate 4 can rotate freely relative to the static valve plate 5; a spring 26 is arranged between the top of the movable valve plate 4 and the inner cavity top wall of the separation chamber 2, and the spring 26 connects the movable valve plate 4 and the static valve plate Tablet 5 is pressed tightly.

[0057] The static valve plate 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com