Pressurized oxygenerator

A technology of oxygen generator and air compressor, which is applied in the direction of inorganic chemistry, oxygen preparation, oxygen/ozone/oxide/hydroxide, etc., which can solve the problem that compressed air is not easy to absorb towers, the purity of oxygen generator equipment is reduced, and it is easy to wriggle Even problems such as pulverization, to achieve the effect of accelerating fluidity, simple structure, and reducing creep

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in combination with specific embodiments.

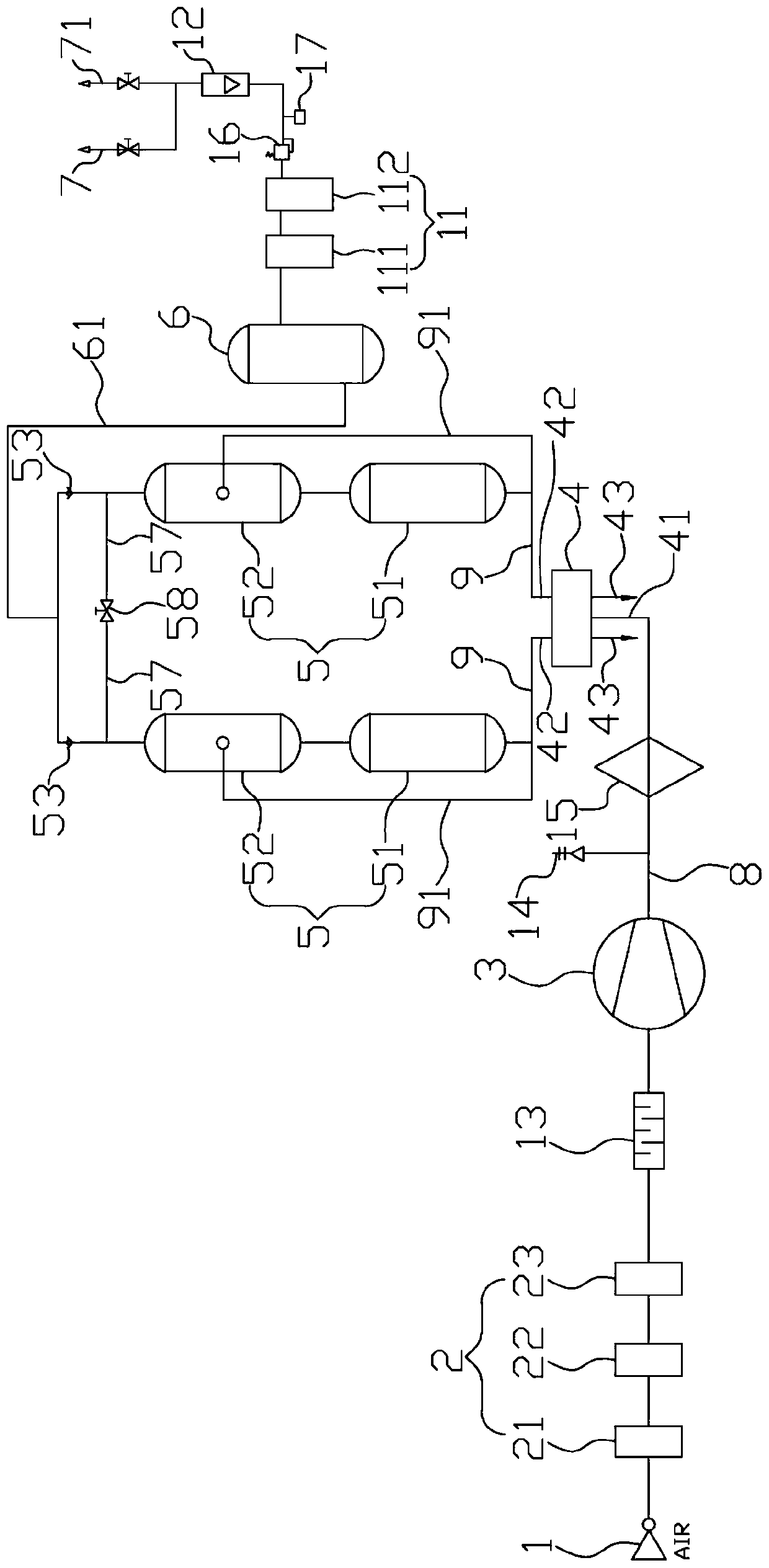

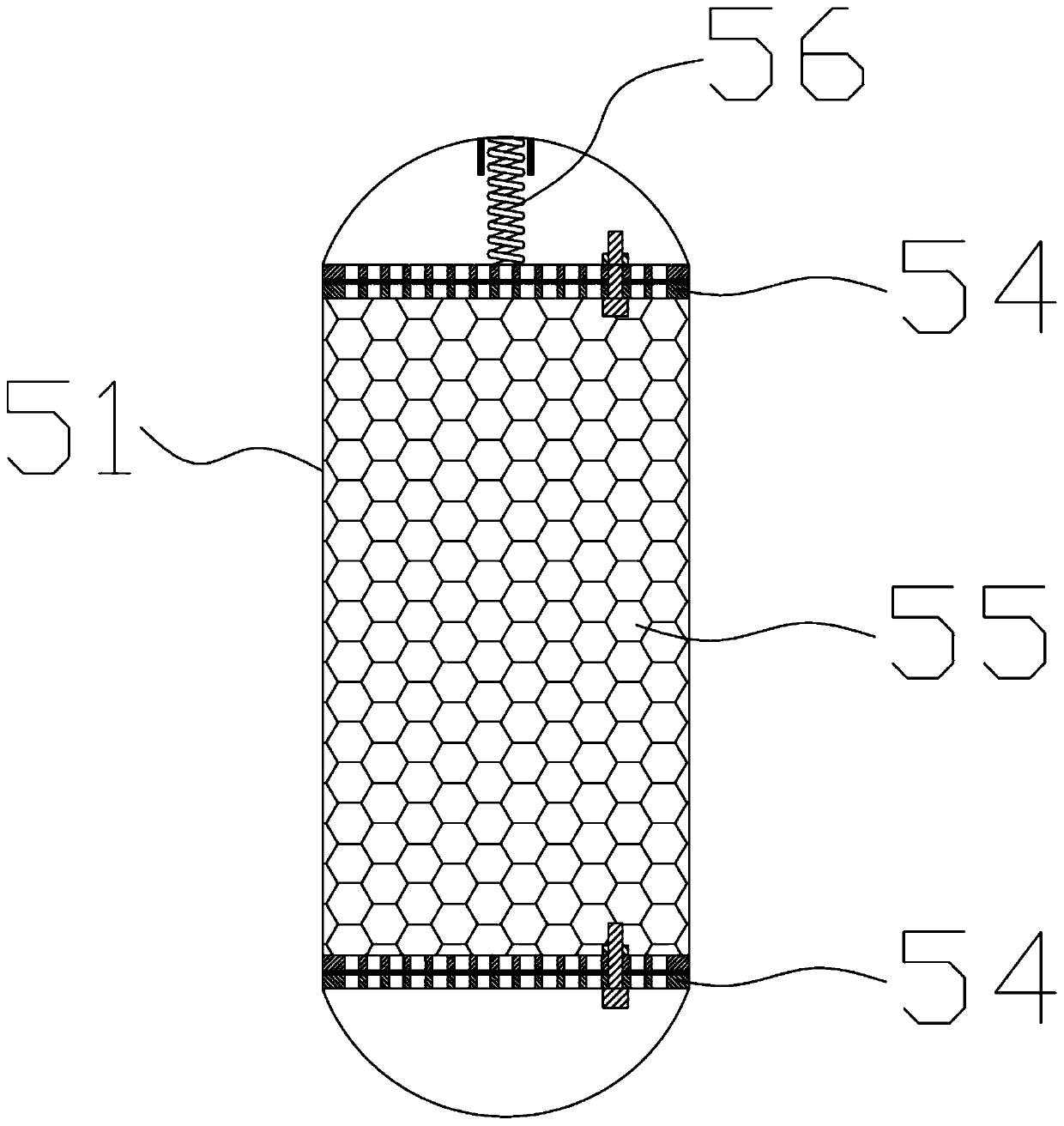

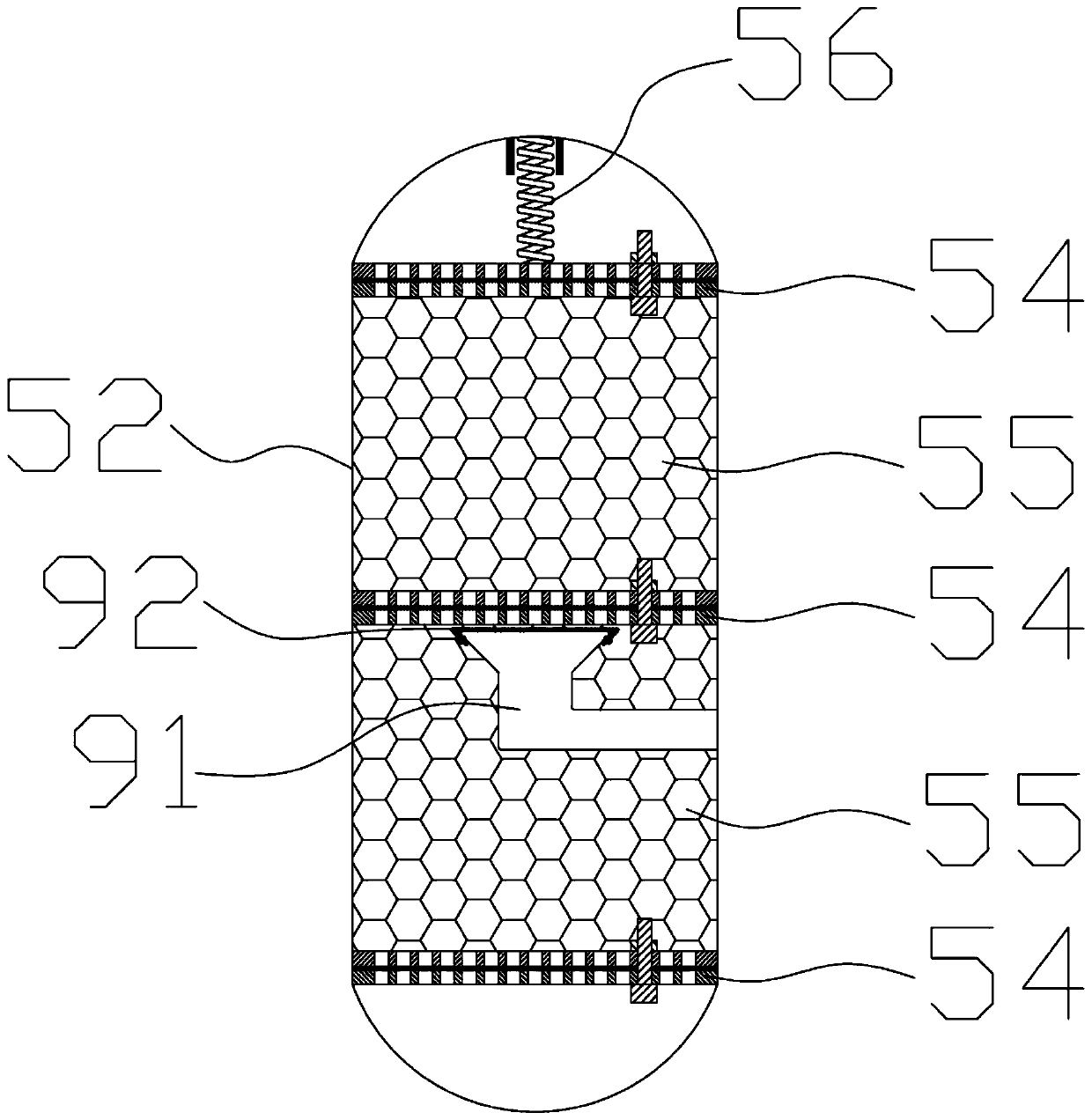

[0023] Such as figure 1 As shown, the pressurized oxygen concentrator according to one embodiment of the present invention includes an air inlet port 1, an air filter group 2, an air compressor 3, a solenoid valve 4, an adsorption tower group 5, an oxygen buffer tank 6 and oxygen Outlet pipeline 7. The air inlet end 1 is communicated with the inlet of the air filter group 2, the outlet of the air filter group 2 is communicated with the inlet of the air compressor 3, and the outlet of the air compressor 3 is communicated with the inlet of the solenoid valve 4 through the intake manifold 8. The air filter group 2 comprises the first air filter 21, the second air filter 22 and the third air filter 23 connected in sequence, and the air is dedusted, degreased and dried, at the outlet of the third air filter 23 and An intake muffler 13 is installed between the inlets of the air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com