Gel application spraying system for optical fiber cables

An optical fiber cable and ointment technology, applied in the directions of light guides, optics, jetting devices, etc., can solve the problems of difficulty in achieving the best, increasing the application amount, and ointment overflow, and achieves uniform distribution of the ointment and guarantees accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

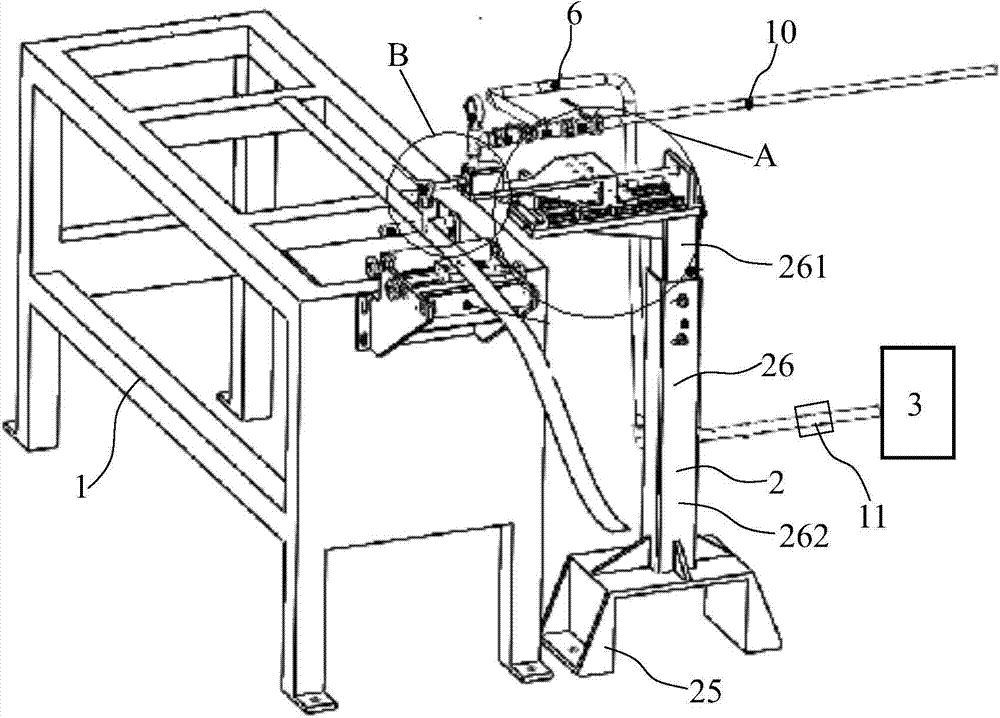

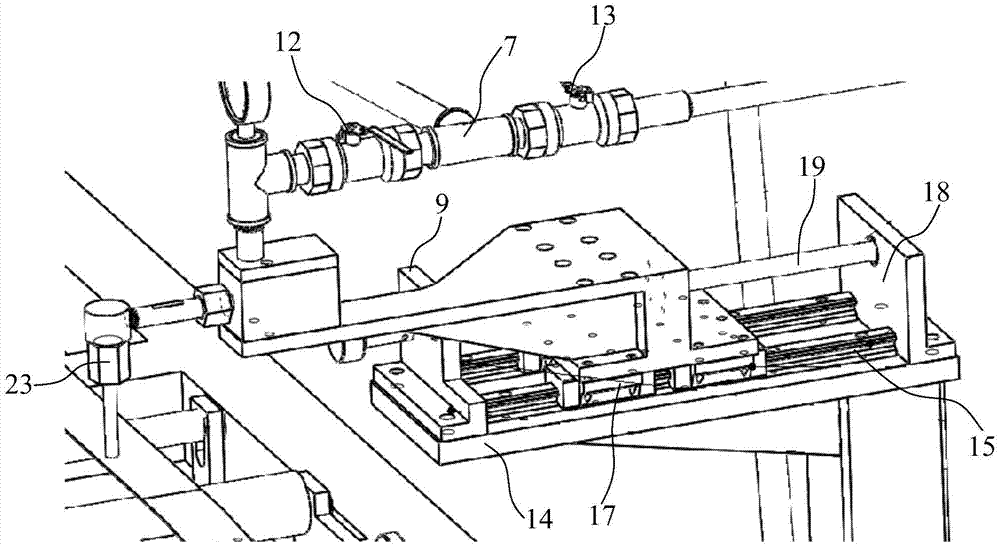

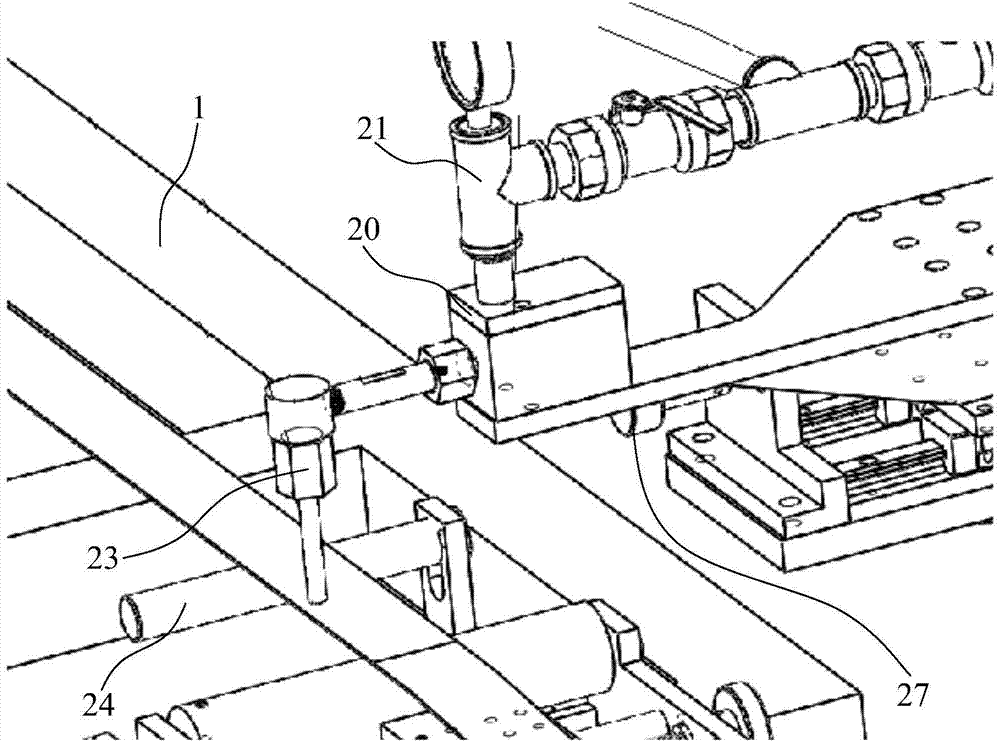

[0029] Embodiment: A spraying system for coating optical fiber and cable with ointment, including a longitudinal package platform 1, a support frame 2, an oil storage tank 3, a spray head mechanism 4 and a support mechanism 5, and the oil storage tank 3 is connected by an oil delivery pipe 6 To the first port of the three-way joint 7, the second port of the three-way joint 7 is connected to the spray head mechanism 9 through the oil inlet pipe 8, and the third port of the three-way joint 7 is connected to the oil storage tank 3 through the oil return pipe 10, so The first valve 11, the second valve 12 and the third valve 13 are respectively installed on the oil delivery pipe 6, the oil inlet pipe 8 and the oil return pipe 10, and the support mechanism 5 is installed on the longitudinal package platform 1;

[0030] The surface of the base 14 of the support frame 2 is fixed with two x-direction rails 15, and the x-direction rails 15 are embedded in the groove of the x-direction s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com