Auxiliary tool for replacing insulator and method for replacing insulator using the same

A technology of auxiliary tools and insulators, applied in the direction of overhead lines/cable equipment, etc., can solve the problems of line tripping, large conductor depression force, and large conductor depression force, etc., to avoid tripping accidents, ensure domestic electricity consumption, The effect of the overall structure is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

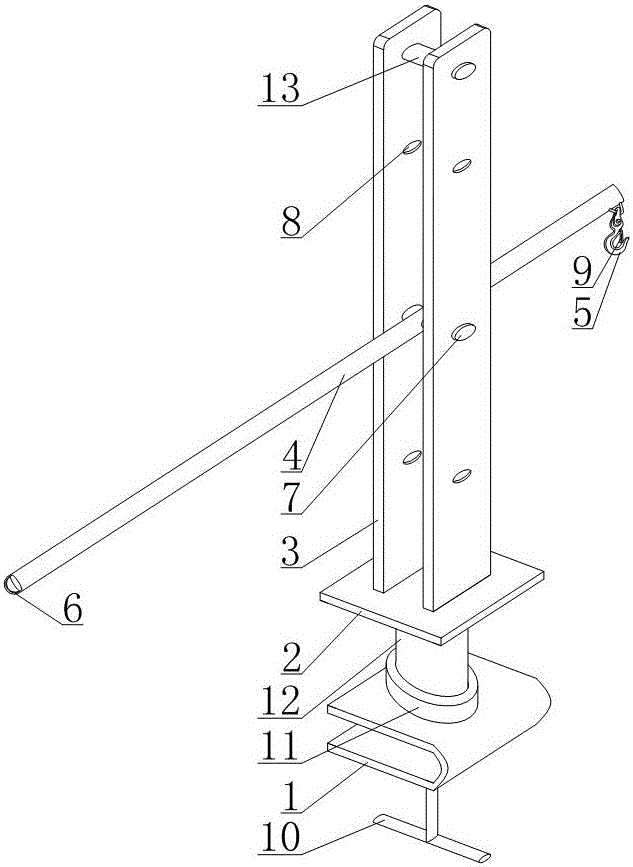

[0021] Such as figure 1 As shown, the auxiliary tool for insulator replacement includes a base 1, a bottom plate 2, a support limit plate 3, a lever 4, a hook 5, a pull ring 6 and a positioning shaft 7, wherein the base 1 of this embodiment is a U-shaped structure, and its The U-shaped opening is located on one side to form a bayonet, and the bottom plate 2 is fixed above the base 1 . In the present embodiment, the supporting limiting plate 3 adopts a vertically arranged rectangular plate, and the number of supporting limiting plates 3 is two. The lever 4 in this embodiment is provided with through holes that run through its opposite sides. The positioning shaft 7 is horizontally arranged and passes through the through holes on the lever 4. The two ends of the positioning shaft 7 are respectively connected with two support limit plates 3. The hooks 5 and the pull ring 6 are connected to the two ends of the lever 4 respectively. In the specific setting of this embodiment, the...

Embodiment 2

[0024] This embodiment makes the following further limitations on the basis of Embodiment 1: the support limiting plate 3 of this embodiment is provided with a plurality of positioning holes 8 passing through its opposite side walls, wherein the plurality of positioning holes 8 The vertical direction of the limiting plate 3 is equidistantly arranged, the number of positioning holes 8 on the two supporting limiting plates 3 is the same and the positions correspond to each other, and the positioning shaft 7 is connected with the supporting limiting plate 3 after passing through the positioning holes 8. The positioning shaft 7 of this embodiment is realized by using bolts, the positioning shaft 7 passes through the positioning holes 8 of the two support limit plates 3, and a nut is sleeved on the positioning shaft 7, and then the positioning shaft 7 is fixed on the support limit plate 3 superior. When the auxiliary tool of this embodiment is applied, the positioning shaft 7 can p...

Embodiment 3

[0026] This embodiment makes the following further limitations on the basis of Embodiment 1 or Embodiment 2: This embodiment also includes a limiting piece 9, one end of the limiting piece 9 is hinged to the connecting end of the hook 5, and the other end is arranged on the hook. 5 and contact with the side where the free end of the hook 5 is located in the half-closed area of the hook 5 . Wherein, the connecting end of the hook 5 is specifically an end of the hook 5 connected to the lever 4, and the free end of the hook 5 is a bent end thereof. When the auxiliary tool of this embodiment is used, the wires leading into the hook 5 are limited by the limiting sheet 9. After the damaged insulator is replaced, the operator on the pole presses down the limiting sheet 9 to take out the wires.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com