Permanent-magnet axial-magnetic-field motor with unit-type layered iron core

A permanent magnet motor, axial magnetic field technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machine parts, etc. Efficiency, good effect, the effect of increasing the effective section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

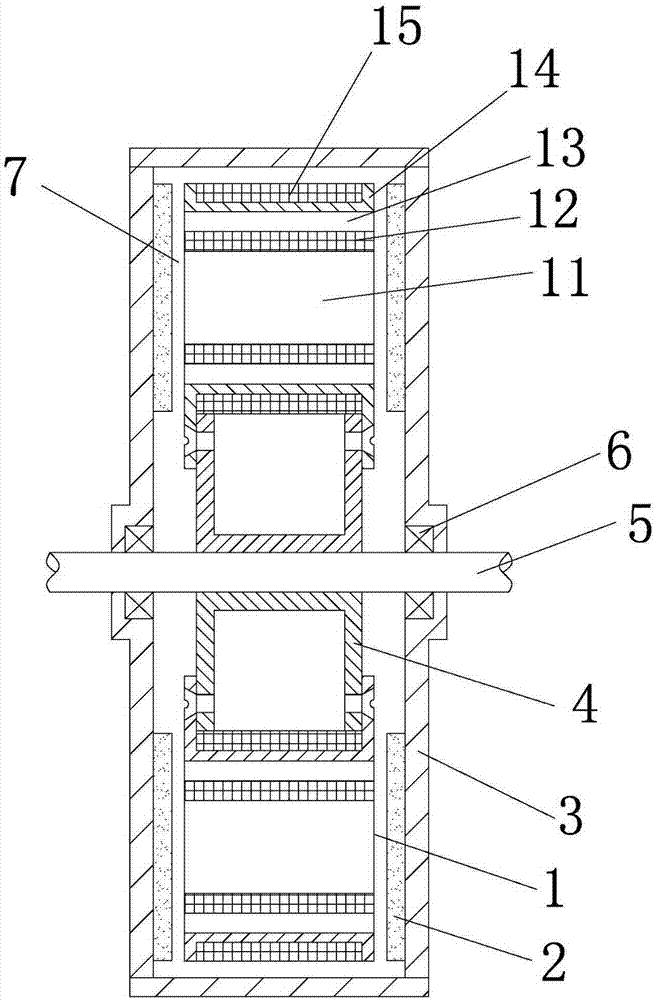

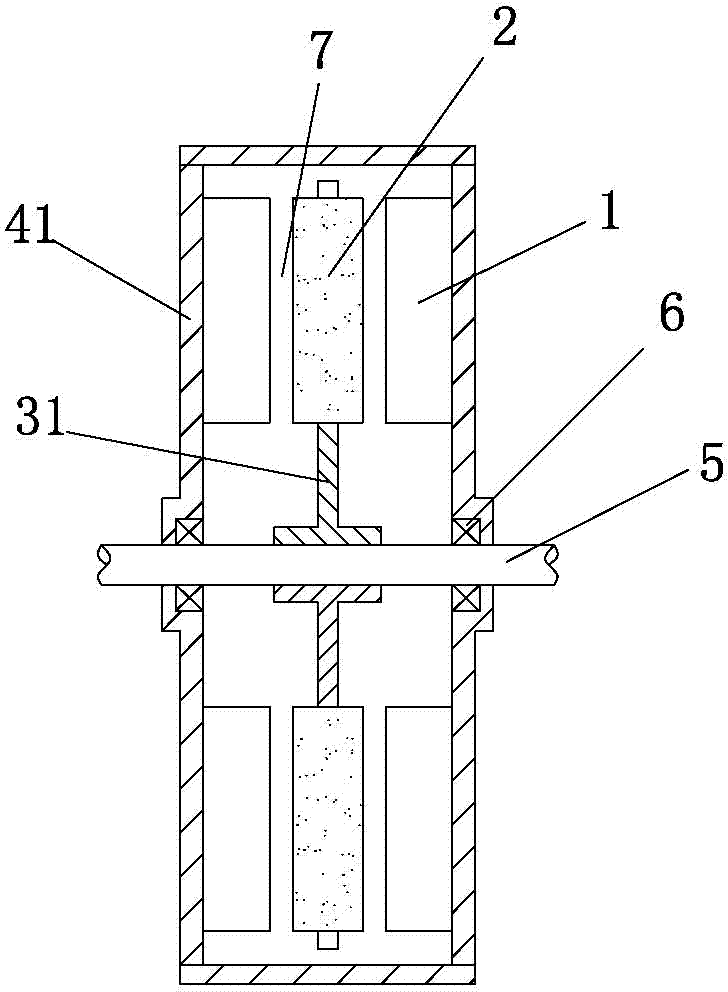

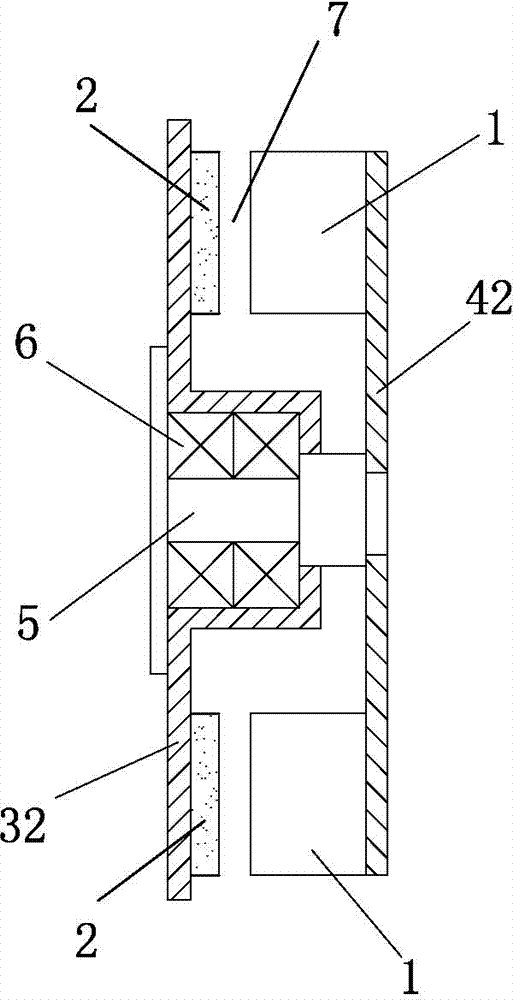

[0016] Depend on Figure 1-7 Given, the present invention includes a layered iron core and an axially magnetized permanent magnet, the layered iron core 1 is fixed on the stator plate 4 to form the stator, the permanent magnet 2 is fixed on the rotor yoke 3 to form the rotor, the stator and the rotor They are all arranged on the shaft 5, the stator and the shaft 5 are fastened together, the rotor rotates around the shaft, the stator and the rotor are arranged opposite to each other in the axial direction, and an air gap 7 is formed between the stator and the rotor to form an axial magnetic field structure. The iron core 1 includes an inner iron core 11, an inner coil 12 wound on the outer circumference of the inner iron core 11, an outer iron core 13 set on the outer circumference of the inner coil 12, and a sleeve 14 se...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap