Continuous casting device and method of large-section round billet

A large-section, round billet technology, applied in the field of continuous casting equipment for large-section round billets, can solve the problems of segregation deterioration, shrinkage cavity, low production efficiency, etc., achieve continuous and semi-continuous casting, and increase the effective section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

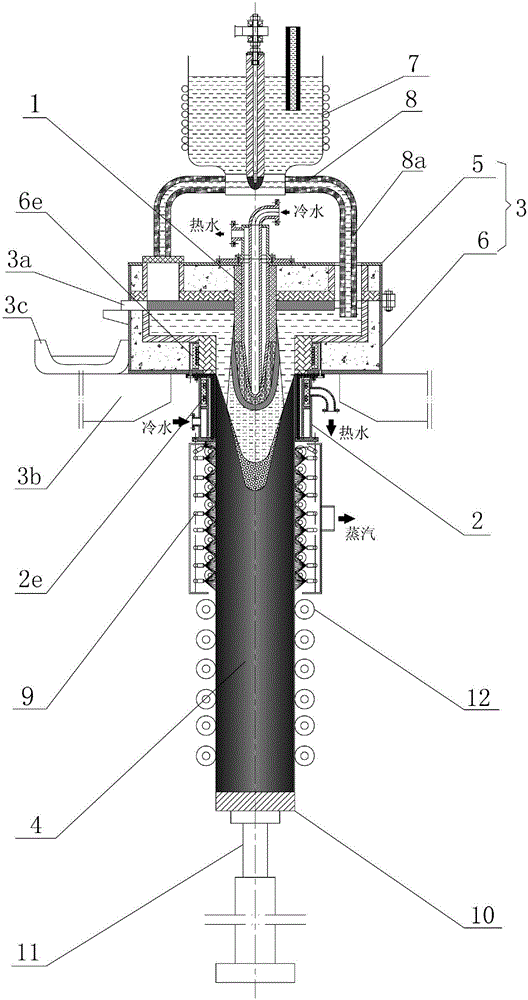

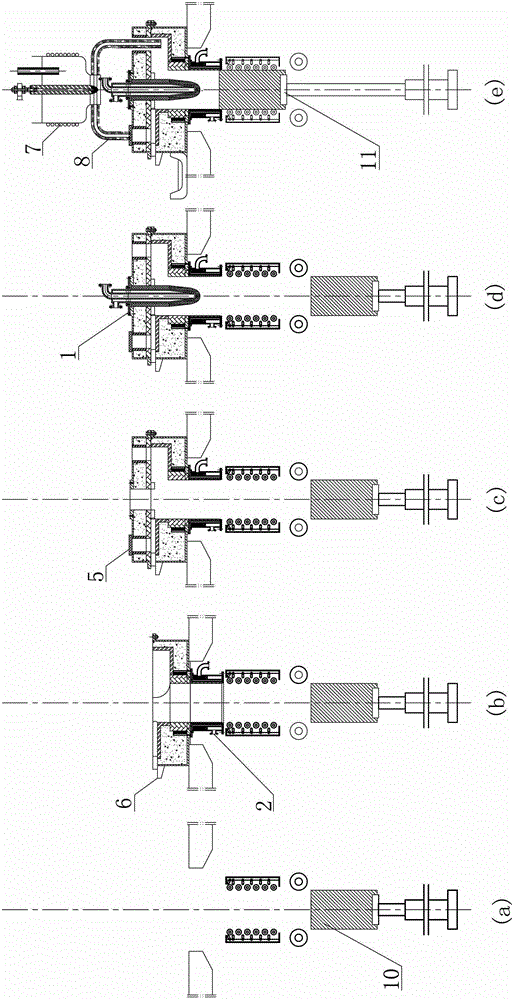

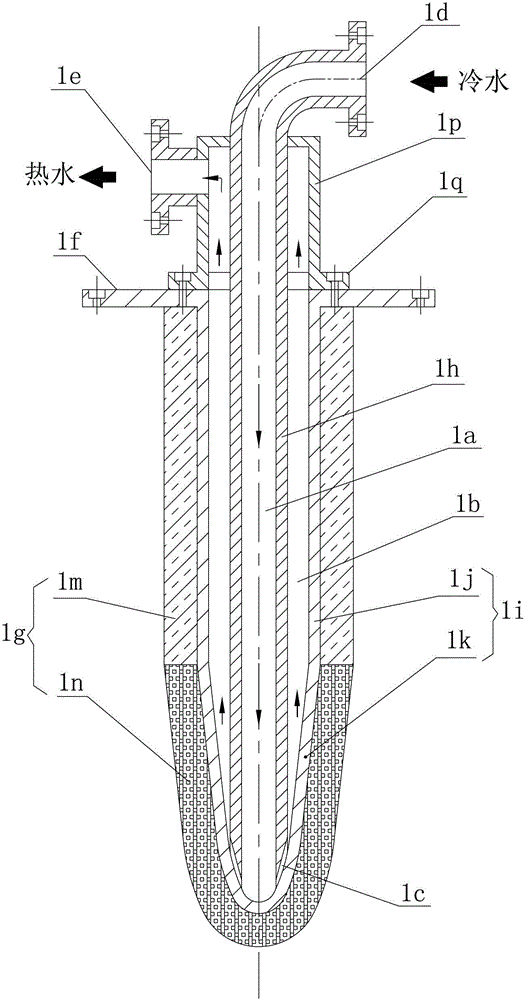

[0026] like figure 1 and figure 2 As shown, the continuous casting device for a large cross-section round billet proposed by the embodiment of the present invention includes an inner mold 1, an outer mold 2, an upper cover mechanism 5, a base mechanism 6, and a cylindrical dummy ingot with a solid circular cross section. Device 10, tundish 7 with heating and strand distributor 8. The insides of the upper cover mechanism 5 and the base mechanism 6 communicate with each other, and the upper cover mechanism 5 and the base mechanism 6 are fixedly connected up and down to form an annular molten metal pool 3 . The outer crystallizer 2 is fixedly connected under the base mechanism 6; the inner crystallizer 1 is an inverted rocket head structure, and the inner crystallizer 1 is fixedly connected to the upper cover mechanism 5, and the lower part of the inner crystallizer 1 It penetrates the inside of the upper cover mechanism 5 and the base mechanism 6, so that the lower part of th...

Embodiment approach 2

[0081] The embodiment of the present invention also proposes a method for casting a large-section continuous casting slab, which includes the steps of:

[0082] A. Provide inner crystallizer 1, outer crystallizer 2, upper cover mechanism 5 and base mechanism 6; the inside of base mechanism and upper cover mechanism 5 communicate with each other, upper cover mechanism 5 and base mechanism 6 are fixedly connected up and down; outer The crystallizer 2 is fixedly connected under the base mechanism 6; the inner crystallizer 1 is an inverted rocket-head structure, and the inner crystallizer 1 is fixedly connected to the upper cover mechanism 5, and the lower part of the inner crystallizer 1 passes through It is arranged inside the upper cover mechanism 5 and the base mechanism 6, so that the lower part of the inner mold 1 is located inside the outer mold 2, and is concentrically surrounded by the outer mold 2;

[0083] B. Provide a cylindrical dummy 10 with a solid circular cross se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com