Method of setting solder balls on a printed circuit board

A technology of printed circuit boards and solder balls, which is applied in the direction of printed circuits, printed circuit manufacturing, printed circuit components, etc., and can solve the problem of insufficient heat dissipation by opening windows on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objects, features and advantages of the present invention more clearly understood, the specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

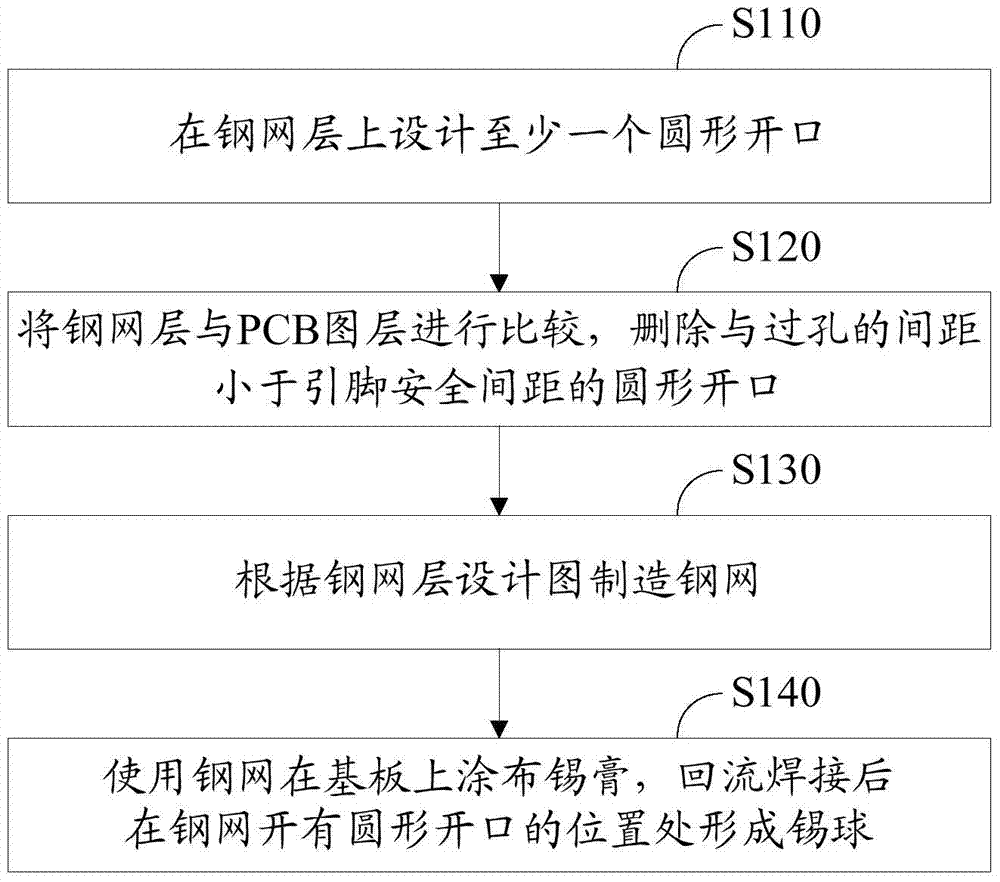

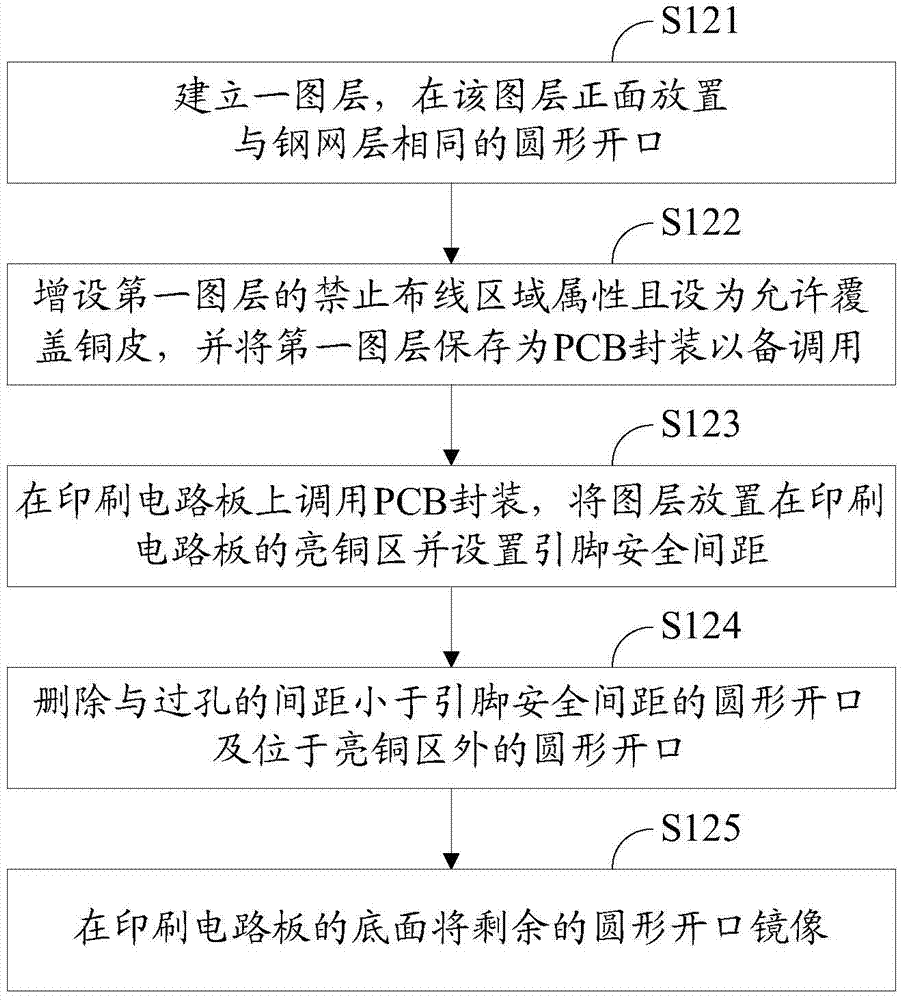

[0017] The present invention enhances the heat dissipation of the printed circuit board by arranging tin balls at suitable positions on the surface of the printed circuit board (PCB), and utilizing the good thermal conductivity of the tin balls. figure 1 It is a flow chart of a method for arranging solder balls on a printed circuit board in one embodiment, including:

[0018] S110, designing at least one circular opening on the steel mesh layer.

[0019] In the manufacturing process of the printed circuit board, it is necessary to apply solder paste on at least one side of the PCB, and the stencil will cover the PCB when the solder paste is applied, so the shape and size of the tin formed on the PCB are Determined by the opening of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com