Locking mechanism for a belt retractor

一种安全带卷收器、锁紧机构的技术,应用在皮带收紧器等方向,能够解决构件磨损等问题,达到好噪声特性、高稳定性、保障耐久性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

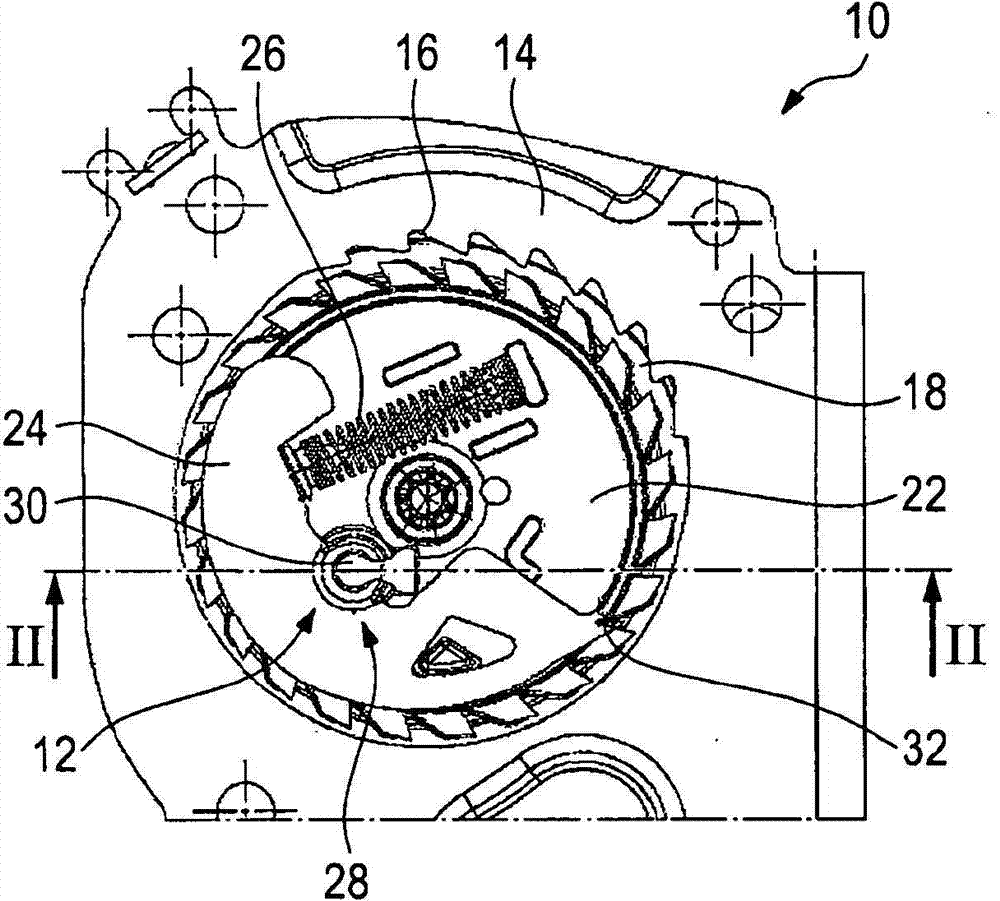

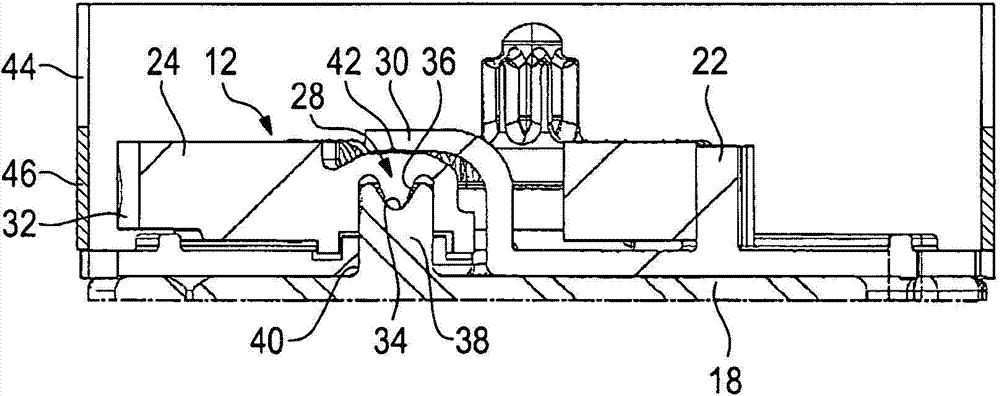

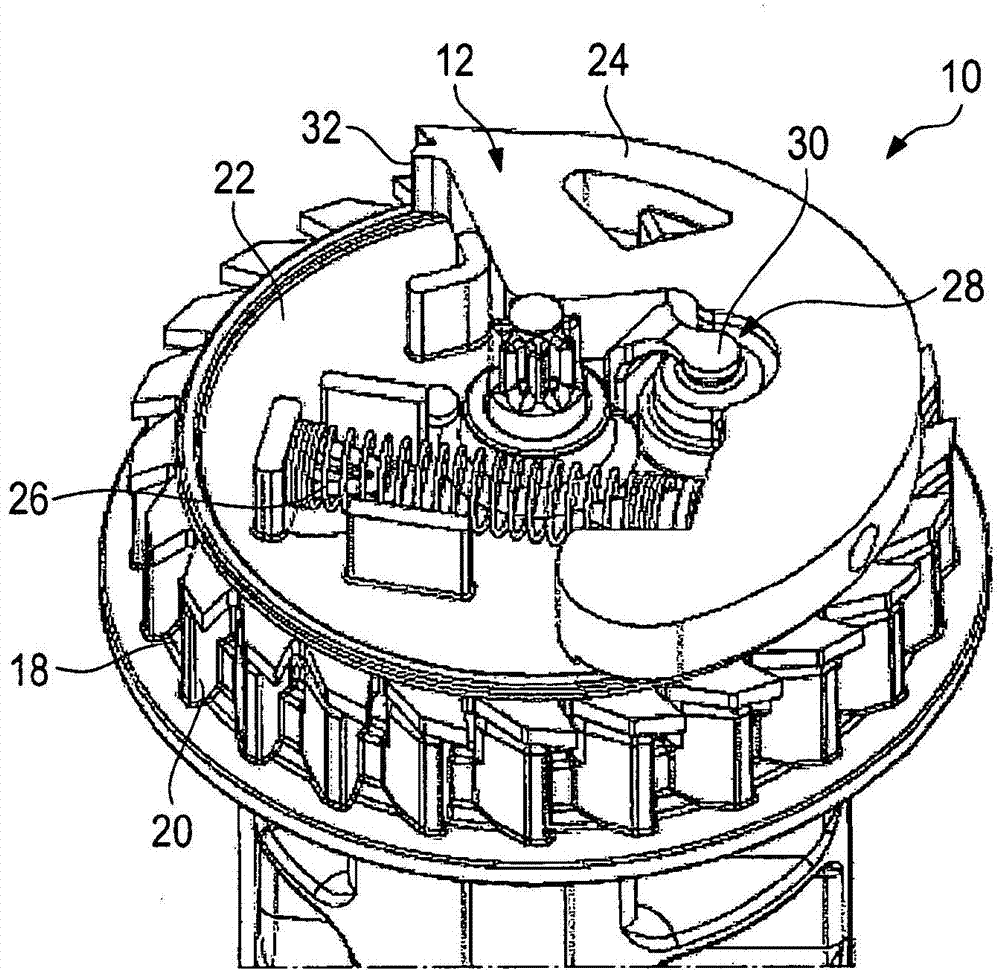

[0022] figure 1 Shown is a seat belt retractor 10 with a locking mechanism 12 according to the invention. The belt retractor 10 has a frame 14 with a toothing region 16 . Furthermore, the belt retractor 10 has a belt reel 18 , the radial edge of which has teeth 20 . The toothing 20 of the belt reel 18 cooperates, if necessary, with the toothing region 16 of the frame 14 in order to lock the rotational movement of the belt reel 18 . Furthermore, the belt retractor 10 has a splice reel 22 which is driven by the belt reel 18 .

[0023] The locking mechanism 12 has an inertia element 24 which is coupled rotatably and prestressed to the engagement disk 22 via a spring 26 . In addition, the inertial element 24 is supported on bearings 28 . In order to stabilize the mounting of the inertial element 24 in the bearing 28 , an elastic holding element 30 , also referred to as a spring element, is provided. In addition, inertial element 24 has a pawl 32 .

[0024] exist figure 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com