Variable displacement swash-plate compressor

A variable type, swash plate type technology, applied in liquid variable volume machinery, mechanical equipment, machine/engine, etc., can solve the problems of unstable tilt angle and the influence of the refrigerant pulsation of the actuator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

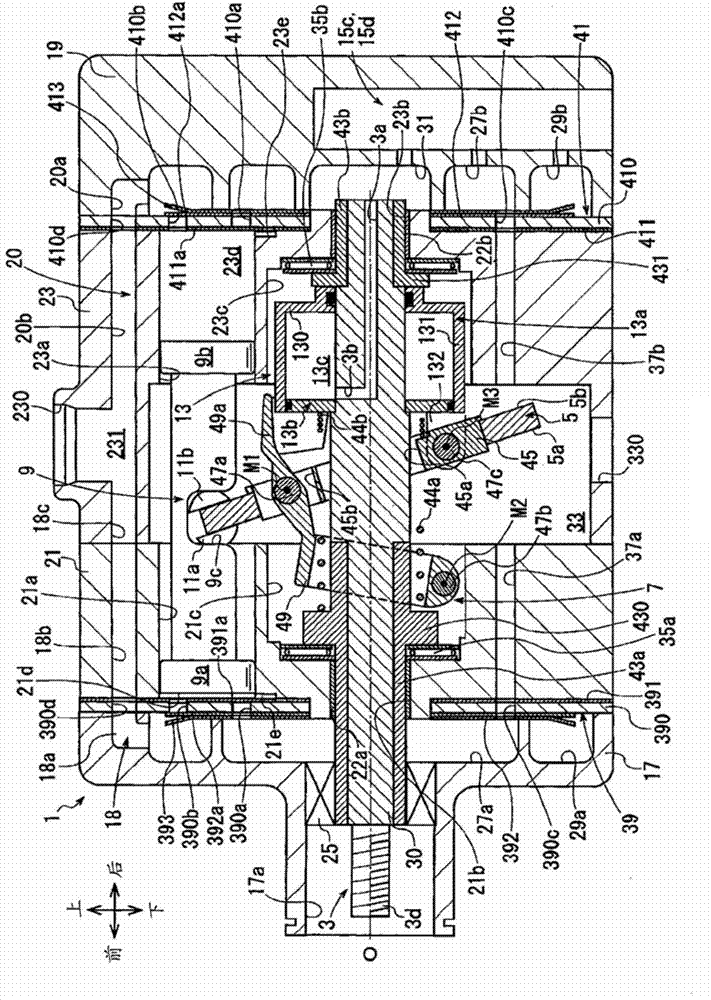

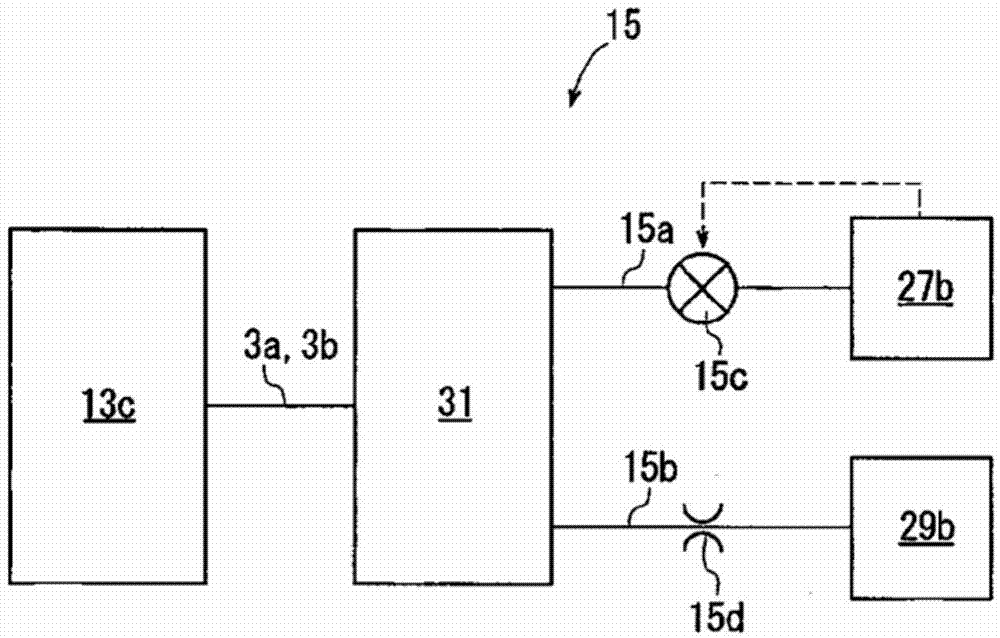

[0023] Such as figure 1 As shown, the compressor of the first embodiment includes: a housing 1, a drive shaft 3, a swash plate 5, a connecting rod mechanism 7, a plurality of pistons 9, a pair of sliding shoes 11a, 11b, an actuator 13 and figure 2 The control mechanism 15 is shown.

[0024] Such as figure 1 As shown, the housing 1 has: a front housing 17 located on the front side of the compressor; a rear housing 19 located on the rear side of the compressor; a first cylinder block located between the front housing 17 and the rear housing 19 21. The second cylinder block 23; and the first valve forming plate 39 and the second valve forming plate 41.

[0025] A protrusion 17 a protruding forward is formed on the front case 17 . A shaft seal 25 is arranged in this projection 17a. In addition, a first suction chamber 27 a and a first discharge chamber 29 a are formed in the front housing 17 . The first suction chamber 27 a is located radially inside the front housing 17 . ...

no. 2 approach

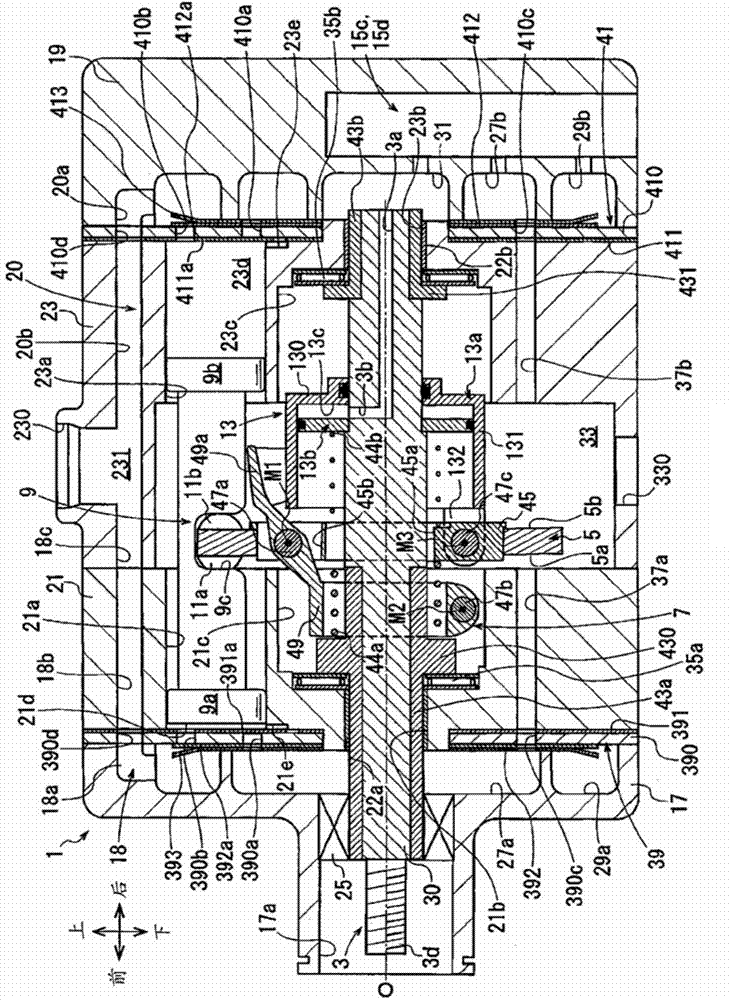

[0098] Such as Figure 4 As shown, the compressor of the second embodiment has: a housing 201, a drive shaft 203, a swash plate 205, a connecting rod mechanism 207, a plurality of pistons 209, a plurality of pairs of sliding shoes 211a, 211b, an actuator 213 and Figure 5 The control mechanism 16 is shown.

[0099] Such as Figure 4 As shown, the housing 201 has: a front housing 217 located at the front side of the compressor, a rear housing 219 located at the rear side of the compressor, a cylinder block 221 located between the front housing 217 and the rear housing 219 and valves Plate 223 is formed.

[0100] The front housing 217 has a front wall 217a extending in the vertical direction of the compressor on the front side, and a peripheral wall 217b integrated with the front wall 217a and extending from the front of the compressor toward the rear. The front case 217 has a substantially cylindrical shape with a bottom formed by the front wall 217a and the peripheral wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com