Coating method of positive/ negative electrode plate of lithium ion battery and positive/ negative electrode plate

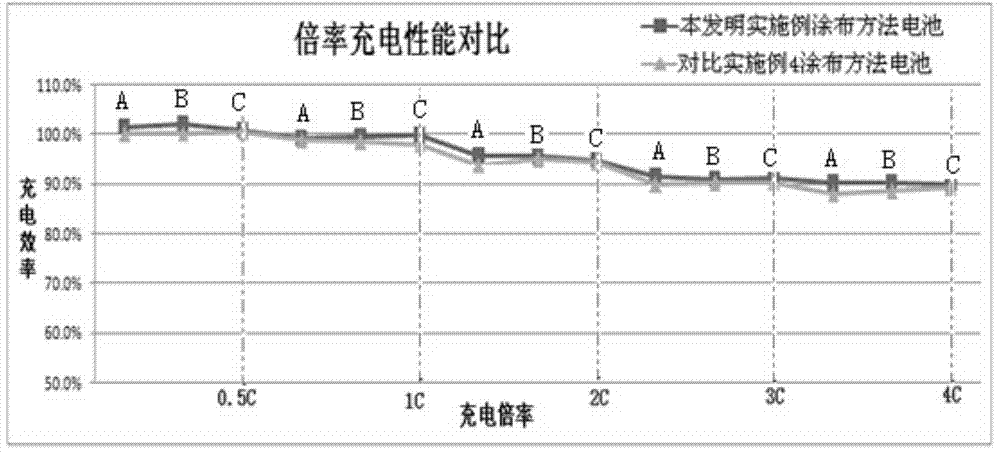

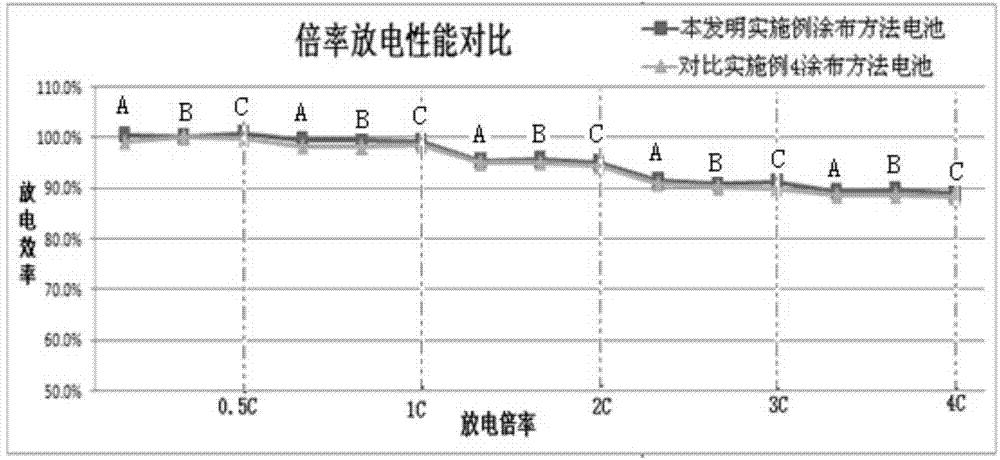

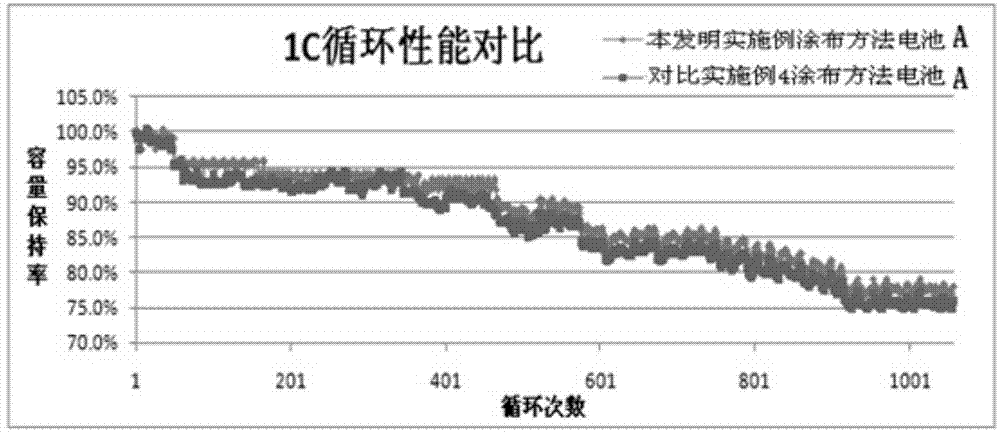

A technology of lithium ion battery and negative pole piece, which is applied to the coating of positive/negative pole piece of lithium ion battery, and the field of positive/negative pole piece, can solve the problem of lack of systematic research and control of the conductivity of the coated pole piece, charging and discharging. The problems of poor rate and large internal resistance of the battery can achieve the effect of battery rate charge-discharge and cycle performance improvement, resistivity reduction and uniform distribution.

Active Publication Date: 2015-07-08

YINLONG ENERGY CO LTD

View PDF4 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The basic principle of the traditional coating process is to require the positive and negative electrode slurry to be baked and dried after passing through the oven of the coating machine, and the adhesion of the coating should be qualified. However, there is no sys

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a coating method of a positive/ negative electrode plate of a lithium ion battery and a positive/ negative electrode plate. The coating method comprises the step of conveying positive electrode size or negative electrode size to a coating machine to coat, wherein a drying box of the coating machine is divided into a front high temperature area, a medium low pressure area and a rear high temperature area; the temperature and circulating air quantity of each section are shown as follows: the temperature of the drying box in the front high temperature section is 125 to 135 DEG C and the circulating air quantity is 35 to 30Hz; the temperature of the drying box in the medium low temperature section is 105 to 125 DEG C and less than that of the drying box at the front high temperature section, and the circulating air quantity is 30 to 45Hz; the temperature of the drying box in the rear high temperature section is 125 to 135 DEG C and more than that of the drying box at the medium low temperature section, and the circulating air quantity is 35 to 50Hz. With the adoption of the coating method, the resistivity of the plate can be reduced; the conductivity can be improved; the inner resistance of the battery can be reduced; the charge-discharge rate and circulating performance of the battery can be improved.

Description

technical field [0001] The invention relates to the field of lithium ion batteries, in particular to a method for coating positive / negative pole pieces of lithium ion batteries and the positive / negative pole pieces. Background technique [0002] As the application fields of lithium-ion batteries become more and more extensive, the client's requirements for its performance are also getting higher and higher. The basic principle of the traditional coating process is to require the positive and negative electrode slurry to be baked and dried after passing through the oven of the coating machine, and the adhesion of the coating should be qualified. However, there is no systematic research and analysis on the electrical conductivity of the coated electrode. control. If the resistivity of the coated pole piece is too high, it will lead to large internal resistance of the battery, poor charge and discharge rate and poor cycle performance. Therefore, it is obviously necessary to e...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B05D1/28B05D3/02H01M4/13H01M4/139

CPCY02E60/10

Inventor 付强蔡惠群詹世英李海军陈晓龙严章术马美品魏银仓张兵

Owner YINLONG ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com