One-time molding device for automatic feeding tool parts

A forming device and automatic feeding technology, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor cost input, low work efficiency, difficult molding parts pass rate, etc., and achieve the goal of reducing labor cost Investment, the effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below, the technical solution of the present invention will be described in detail through specific examples.

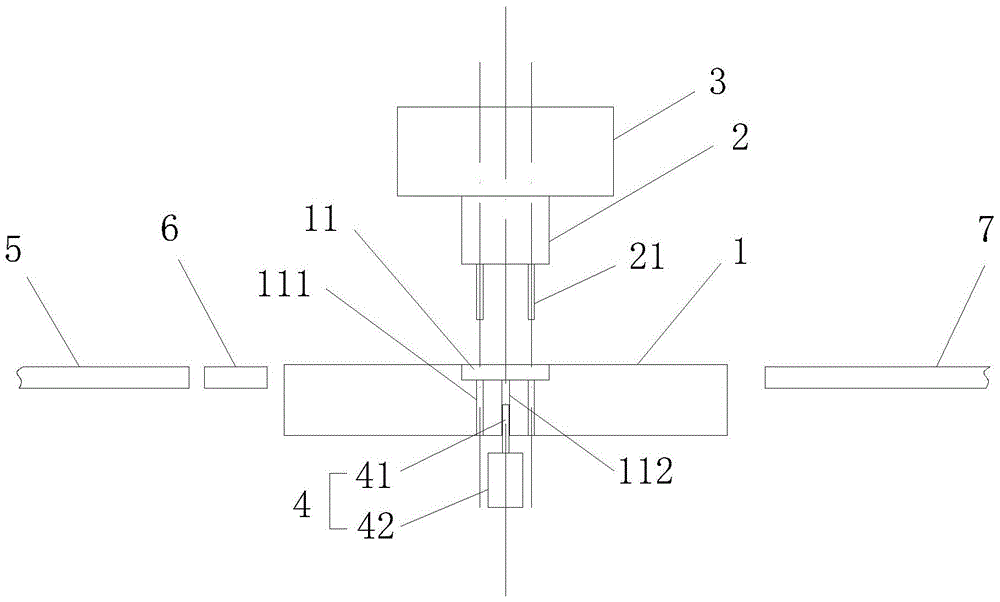

[0014] like figure 1 as shown, figure 1 It is a structural schematic diagram of a one-time forming device for automatic feeding tool parts proposed by the present invention.

[0015] refer to figure 1 , an automatic feeding tool part one-time forming device proposed by the embodiment of the present invention is used for automatic feeding and forming of blades or connecting pieces, including: a feeding device 5 and a forming device arranged side by side.

[0016] The feeding device 5 is arranged on the feeding end of the molding device and is used to convey the blank to the molding device. The feeding device 5 includes a conveying roller and a first drive mechanism for driving the conveying roller for rolling transmission; the both sides of the feeding device 5 conveying line are respectively provided There is a pusher mechanism 6 for trimming the blank, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com