Gear hobber sharpening machine

A gear hob, grinding machine technology, applied to milling cutters, grinding workpiece supports, metal processing equipment, etc. The effect of reducing the amount of wear, increasing the service life and reducing the amount of wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

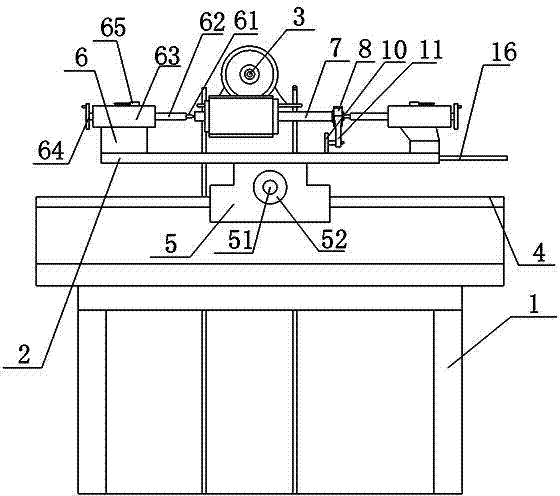

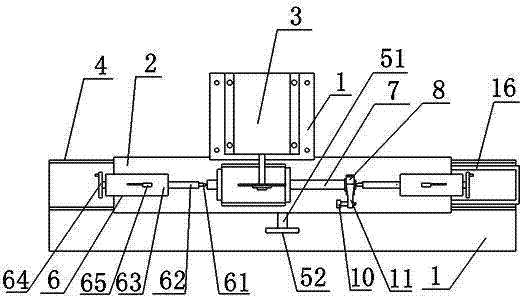

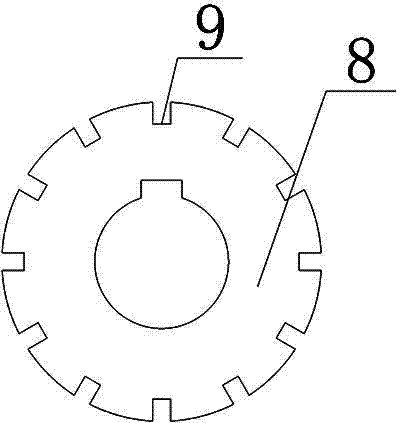

[0017] Such as figure 1 with figure 2 Shown, a kind of gear hob grinding machine, it comprises frame 1, mobile platform 2, gear positioning tooling and grinder 3, guide rail 4 is installed on the described frame 1, the bottom of described mobile platform 2 A sliding seat 5 is provided, and the sliding seat 5 can move along the guide rail 4. The left and right ends of the mobile platform 2 are equipped with thimble devices 6. The gear positioning tool includes a gear shaft 7, and the gear shaft 7 rests on the Between the two thimble devices 6, an index plate 8 is installed on the right end of the gear shaft 7, as image 3 As shown, the index plate 8 is provided with a groove 9 having the same number of teeth as the gear, and the mobile platform 2 is also provided with a positioning column 10, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com